Industries We Serve — Wear Parts Engineered for Your Operation

Every industry has unique demands—abrasive hard rock in mining, specification control in aggregates, continuous operation in cement, and contamination management in recycling. We engineer wear parts specifically for your operational reality, not generic applications. Tell us your industry, equipment, and challenges—we’ll recommend the right solution.

- 4Core Industries

- 35+Years Experience

- 50+Countries Served

- 500+Equipment Models

Select Your Industry

Each industry presents unique wear challenges. Click your sector to understand your specific requirements and explore relevant wear part solutions.

Mining & Mineral Processing

24/7 operations, abrasive hard rock, extreme tonnages, underground & surface applications

Aggregates & Quarrying

Product specification control, cubicity requirements, mobile & stationary plants

Cement Manufacturing

Continuous production, high temperatures, energy efficiency, Blaine fineness targets

Recycling & Demolition

Variable feed streams, metal contamination, C&D waste, impact resistance priority

Mining Industry: Where Equipment Endures the Harshest Conditions

Mining operations subject wear parts to conditions no other industry matches—continuous 24/7 operation, highly abrasive silica-rich ores, extreme impact forces, and zero tolerance for unplanned downtime. Whether processing copper, gold, iron ore, coal, or industrial minerals, your wear parts must deliver consistent performance under punishing conditions.

Unique Mining Challenges

- Ore Variability: Hardness fluctuates daily—materials must handle both soft overburden and extremely hard ore zones

- Abrasive Content: High-silica ores (quartz, taconite) cause 3-5× faster wear than limestone

- Continuous Operation: 8,000+ hours/year leaves no margin for premature failures

- Remote Locations: Long lead times for replacement parts make wear life predictability critical

- Tonnage Demands: 50,000-200,000+ TPD throughput requires maximum component durability

Material Selection Priorities

- Maximum Wear Life: Premium alloys (Mn22Cr3, TiC inserts) justify higher cost through extended service intervals

- Impact Toughness: Resistance to catastrophic failure from oversized feed or tramp metal

- Work Hardening: Manganese grades that develop surface hardness under operational stress

- Predictable Wear: Consistent wear patterns enabling planned maintenance scheduling

Equipment Categories for Mining

Mining operations typically require wear parts across the complete comminution circuit:

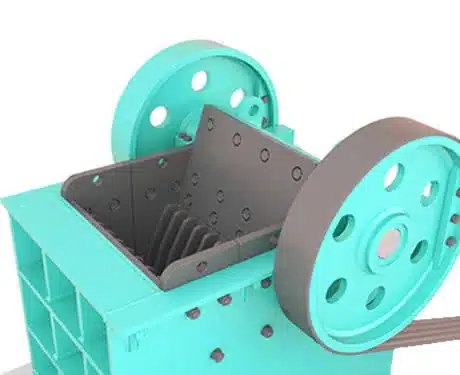

Primary Crushing

Gyratory crushers, large jaw crushers for run-of-mine ore reduction from blast fragmentation to conveyor size.

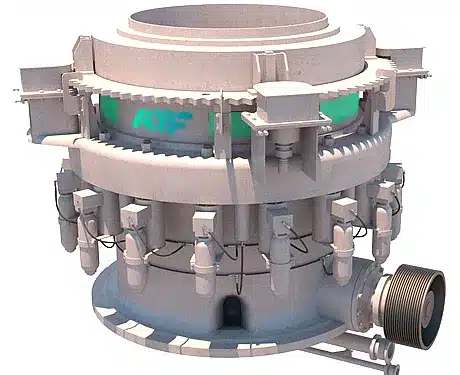

Secondary/Tertiary Crushing

Cone crushers (HP, GP, Symons) for controlled size reduction before grinding circuits.

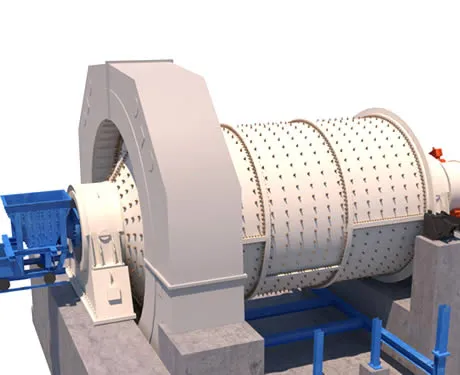

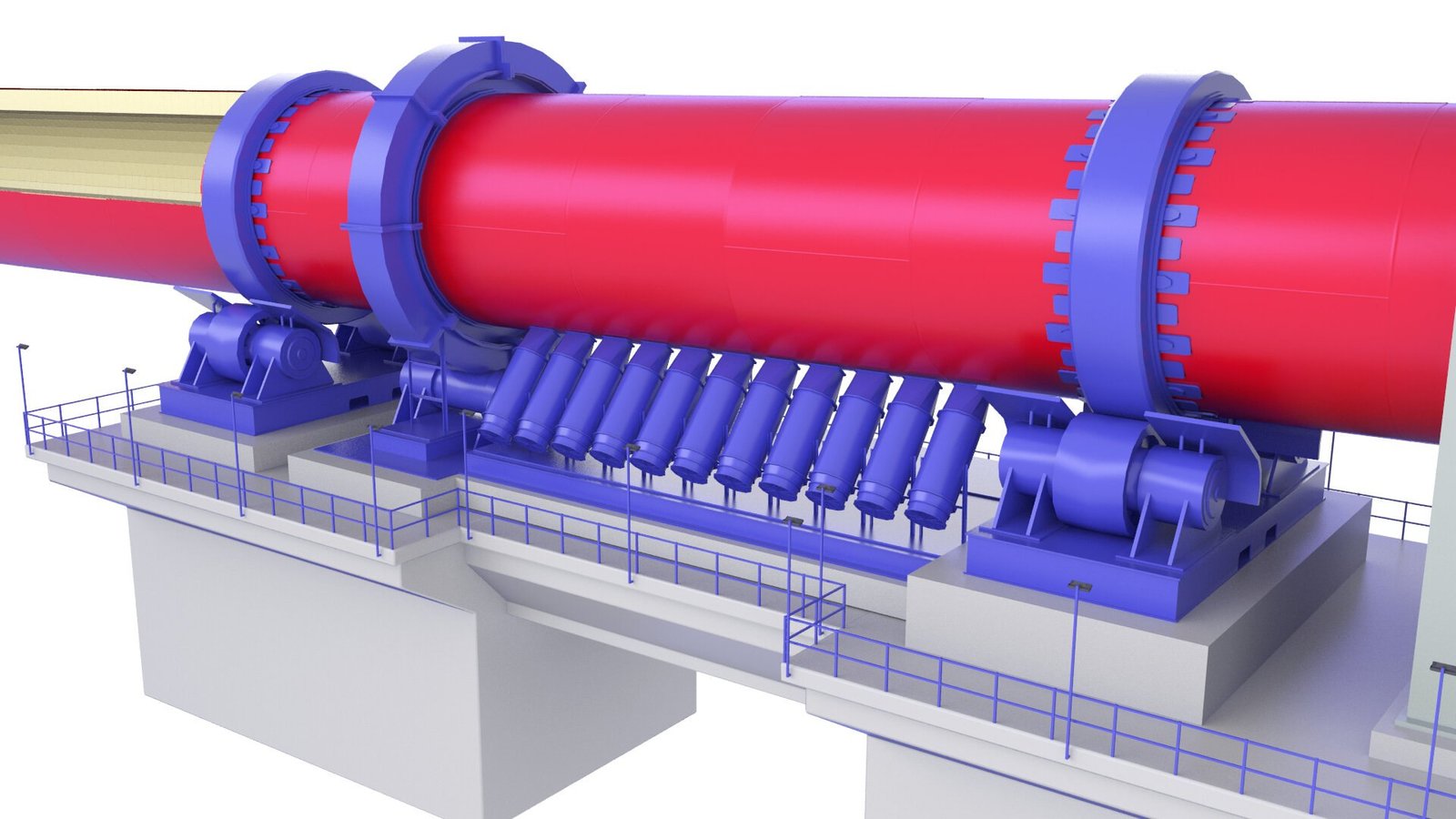

Grinding & Milling

SAG mills, ball mills, rod mills, vertical roller mills for liberation grinding to flotation feed size.

Aggregate Industry: Where Product Quality Defines Success

Aggregate operations face a different challenge than mining—product specification compliance is paramount. Gradation curves, cubicity requirements, and fines content directly impact customer acceptance and pricing. Your wear parts must deliver consistent crushing performance that produces sellable product, not just throughput tonnage.

Unique Aggregate Challenges

- Specification Control: DOT specs, ASTM standards require precise gradation and shape compliance

- Cubicity Requirements: Manufactured sand and asphalt aggregate demand specific particle shapes

- Mobile Operations: Portable plants move between sites—quick changeovers and versatile materials needed

- Cost Sensitivity: Commodity pricing requires competitive cost-per-ton production

- Variable Rock Types: Single quarry may process limestone, granite, and gravel with different wear characteristics

Material Selection Priorities

- Consistent Wear Patterns: Uniform liner wear maintains CSS and product gradation throughout service life

- Profile Optimization: Chamber geometry matched to target product size distribution

- Versatility: Materials that perform across limestone, granite, and recycled concrete

- Cost-Per-Ton Focus: Balance of wear life and material cost for optimal economics

Equipment Categories for Aggregates

Aggregate plants prioritize impact crushers for shape and compression crushers for gradation:

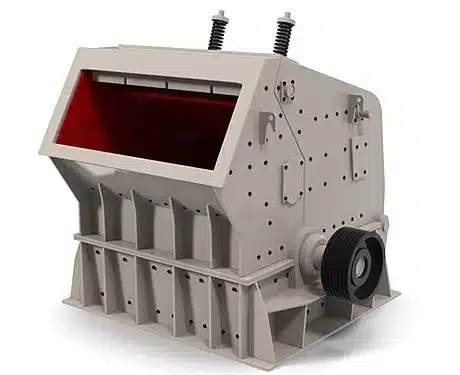

Impact Crushing

HSI and VSI crushers for cubical product shape, manufactured sand, and recycled concrete processing.

Compression Crushing

Cone crushers for controlled secondary/tertiary reduction with precise CSS management.

Primary Reduction

Jaw crushers for quarry face material reduction to secondary crusher feed size.

Cement Industry: Where Continuous Operation is Non-Negotiable

Cement plants operate 330+ days per year with planned shutdowns measured in hours, not days. Unscheduled downtime cascades through the entire production chain—raw mill stoppage affects kiln feed, kiln issues halt clinker production, finish mill problems stop cement dispatch. Your wear parts must deliver predictable service life that aligns with maintenance windows.

Unique Cement Challenges

- Continuous Production: 7,800+ operating hours/year with narrow maintenance windows

- High Temperatures: Clinker at 200-400°C, kiln zones at 1,000-1,450°C require heat-resistant alloys

- Energy Efficiency: Grinding consumes 60-70% of plant electrical cost—liner efficiency directly impacts operating cost

- Product Fineness: Blaine 3,200-4,500 cm²/g targets require consistent grinding performance

- Alternative Fuels: Waste-derived fuels introduce contamination and variable chemistry

Material Selection Priorities

- Predictable Wear: Service life must align with planned shutdown schedules

- Heat Resistance: Hot hardness retention at operating temperatures

- Grinding Efficiency: Liner profiles optimized for specific power consumption

- Thermal Cycling Tolerance: Resistance to cracking from start-stop temperature changes

Equipment Categories for Cement

Cement plants require wear parts from raw material processing through finish grinding:

Raw Material Crushing

Limestone jaw crushers, impact crushers for clay and additives, hammer mills for alternative materials.

Grinding Mills

VRM rollers and tables, ball mill liners for raw meal, coal, and finish cement grinding.

Kiln & Cooler

Heat-resistant components for preheater cyclones, kiln inlet, clinker cooler grates, and clinker breakers.

Recycling Industry: Where Contamination Changes Everything

Recycling operations face a fundamentally different challenge—unpredictable feed streams with embedded metal, rebar, and tramp materials that cause catastrophic wear part failures in seconds. The highest-hardness materials that excel in clean rock applications can shatter on first contact with rebar. Material selection must prioritize impact toughness over maximum hardness.

Unique Recycling Challenges

- Metal Contamination: Rebar, wire mesh, structural steel embedded in concrete cause instant wear part damage

- Variable Feed: C&D waste quality changes daily—clean concrete today, heavily reinforced tomorrow

- Safety Concerns: Brittle wear part failures eject fragments at high velocity

- Mobile Operations: Equipment moves between job sites with varying material characteristics

- Mixed Waste Streams: Asphalt, concrete, brick, block processed together require versatile materials

Material Selection Priorities

- Impact Toughness First: Resistance to catastrophic failure trumps maximum hardness

- Controlled Wear: Gradual wear patterns rather than sudden breakage

- Versatility: Performance across clean and contaminated feed streams

- Safety: Materials that deform rather than shatter under impact

Equipment Categories for Recycling

Recycling operations rely heavily on impact crushing with contamination tolerance:

Impact Crushers

HSI crushers with rebar-tolerant blow bars for C&D concrete and asphalt recycling.

Jaw Crushers

Primary reduction for demolition concrete with structural steel and wire mesh contamination.

Shredders & Hammer Mills

Size reduction for mixed waste, wood waste, and scrap metal processing.

Industry Comparison: How Wear Requirements Differ

Understanding what makes each industry unique helps select the right wear solutions. The same crusher model requires different materials depending on whether it processes copper ore, limestone aggregate, cement raw material, or demolition concrete.

| Factor | Mining | Aggregates | Cement | Recycling |

|---|---|---|---|---|

| Primary Challenge | Extreme abrasion from silica-rich ores | Product specification compliance | Continuous operation requirements | Metal contamination management |

| Operating Hours/Year | 8,000+ (24/7) | 2,500-4,000 (seasonal) | 7,800+ (330+ days) | 1,500-3,000 (project-based) |

| Material Priority | Maximum wear life | Cost-per-ton optimization | Predictable service intervals | Impact toughness |

| Recommended Grade | Mn22Cr3, TiC inserts | Mn18Cr2 standard | High-chrome 18-28% Cr | Martensitic HRC 50-55 |

| Failure Mode Concern | Premature wear-through | Uneven wear affecting gradation | Unscheduled shutdown | Catastrophic breakage |

| Lead Time Tolerance | Low—remote sites need inventory | Medium—seasonal planning | Very low—aligns with shutdowns | High—mobile, project-based |

| Key Equipment | Gyratory, cone, SAG/ball mills | HSI, VSI, cone crushers | VRM, ball mills, kilns | HSI, jaw, shredders |

Industry Success Stories

Real results from operations across mining, aggregates, cement, and recycling—demonstrating how proper material selection and application engineering deliver measurable improvements.

Copper Mine: 45% Cone Liner Life Extension

Challenge: Porphyry copper operation experiencing short cone crusher liner life (780 hours average) with high replacement costs and frequent maintenance shutdowns in remote location.

Solution: Material upgrade from standard Mn18Cr2 to Mn22Cr3 with TiC carbide inserts. Profile optimization improved feed distribution and reduced localized wear patterns.

Results: Liner life increased to 1,135 hours (45% improvement). Annual cost savings of $127,000. Maintenance intervals extended from 32 to 47 days.

Quarry: 75% VSI Rotor Tip Life Improvement

Challenge: Manufactured sand operation using high-cost OEM VSI rotor tips with 220-hour average life in hard limestone. Budget pressures required cost reduction without sacrificing product quality.

Solution: Implemented ceramic MMC composite tips designed specifically for autogenous rock-on-rock crushing applications.

Results: Rotor tip life extended to 385 hours (75% improvement). Cost per ton reduced by 52%. Product cubicity maintained at 0.82. Annual savings: $89,500.

Cement Plant: 69% Ball Mill Liner Life Extension

Challenge: 4.2m × 14m finish cement mill experiencing high power draw and premature liner wear (4,200 hours vs expected 6,000+). Production limitations forced expensive clinker purchases.

Solution: Complete liner profile redesign using chrome-moly white iron (18% Cr, 2.5% Mo) optimized for Blaine fineness target of 3,800 cm²/g.

Results: Liner life extended to 7,100 hours (69% improvement). Power consumption reduced 6.2%. Mill throughput increased 8%. Combined annual savings: $340,000.

C&D Recycler: Zero Blow Bar Breakages

Challenge: Mobile impact crusher processing demolition concrete with heavy rebar contamination. Frequent blow bar breakage causing costly downtime and safety concerns from fragment ejection.

Solution: Switched from brittle high-chrome bars (HRC 62) to tough martensitic steel design (HRC 52-54). Material selection prioritized impact resistance over maximum hardness.

Results: Blow bar breakage eliminated (zero failures in 18 months). Service life: 420 hours average (vs 280 hours with high-chrome). Unscheduled downtime reduced 73%.

Industry Questions & Answers

Common questions about industry-specific wear part requirements, material selection, and operational considerations.

How do I know which material grade is right for my industry?

Why does the same crusher require different materials in different industries?

Can you supply parts for operations spanning multiple industries?

How does operating schedule affect wear part selection?

What makes recycling applications different from virgin rock crushing?

How do cement plant operating temperatures affect material selection?

What lead times should I plan for industry-specific parts?

Do you provide on-site technical support for different industries?

How do I evaluate whether aftermarket parts will perform as well as OEM in my application?

What information do you need to recommend the right parts for my industry?

Explore Our Product Range

Browse wear parts by equipment category. All products available for mining, aggregate, cement, and recycling applications with industry-appropriate material options.

Jaw Crusher Parts

Fixed and swing jaw plates, cheek plates, toggle plates for primary crushing across all industries.

Cone Crusher Parts

Mantles, concaves, feed cones for HP, GP, Symons, and Omnicone crushers in mining and aggregates.

Impact Crusher Parts

Blow bars, impact plates, side liners for HSI and VSI crushers in aggregates and recycling.

Mill & Grinding Parts

SAG, ball, rod, and vertical roller mill liners for mining and cement grinding applications.

Cement Plant Parts

Kiln components, cooler grates, preheater cyclone liners, clinker breaker hammers.

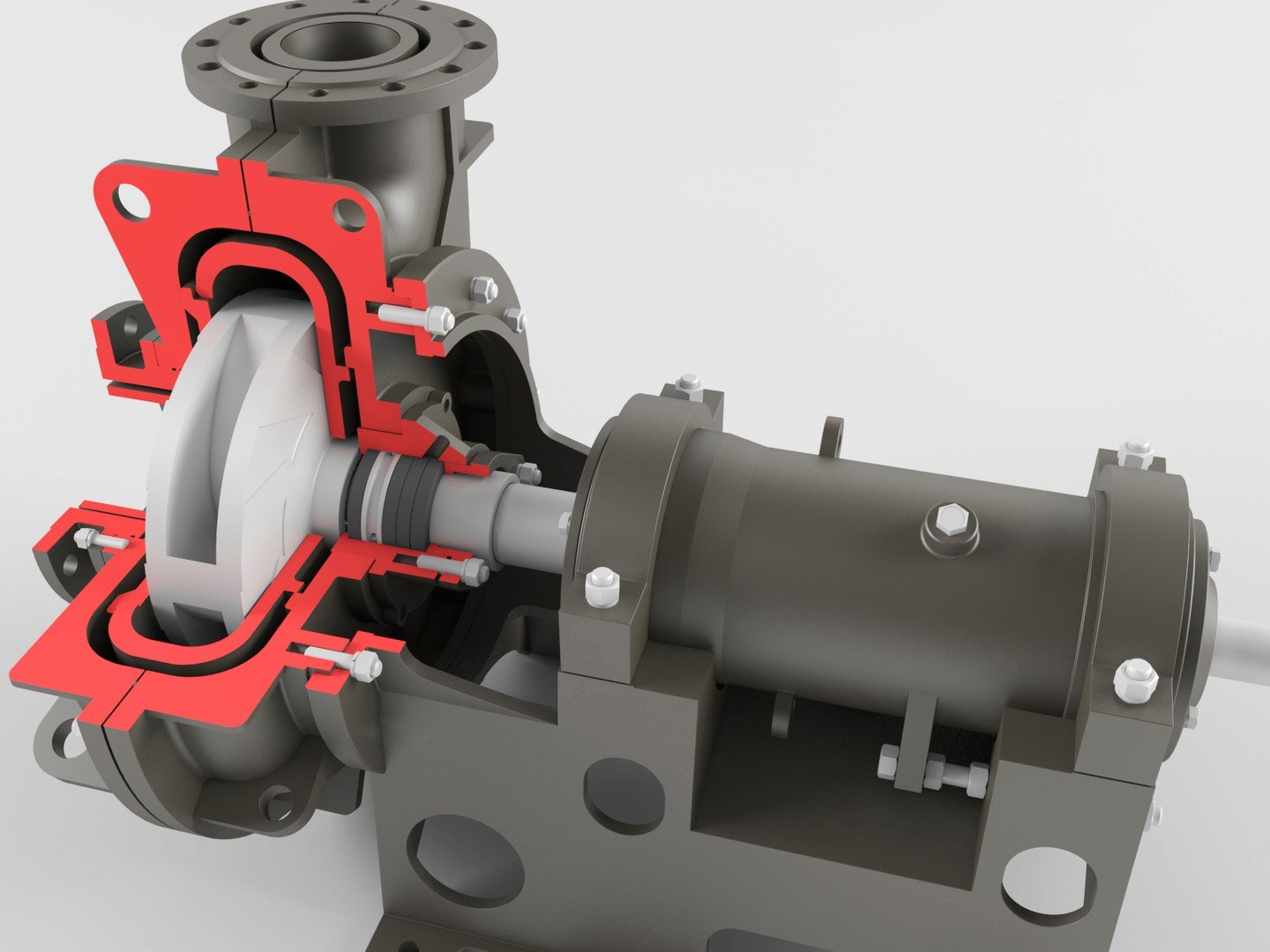

Slurry Pump Parts

Impellers, volute liners, throat bushes for mining and mineral processing pump applications.

Get Your Industry-Specific Quote

Tell us your industry, equipment, and challenges. We’ll recommend the right solution.

35+ years serving mining, aggregates, cement & recycling

Prefer direct contact?

Email: info@atfcs.com

Phone: +1 308 465 1950

What Happens Next?

-

1

Application Review

We analyze your industry, equipment, and operational requirements

-

2

Material Recommendation

Our engineers recommend the optimal solution for your specific application

-

3

Custom Quote

Receive detailed pricing within 24-48 hours

35+ years in mining, aggregates, cement, recycling

Materials matched to your industry requirements

ISO 9001 manufacturing with full material traceability

“ATF understood our cement plant’s specific requirements from the first conversation. The liner recommendations they provided extended our maintenance intervals by 40%.”

— Maintenance Manager, European Cement Producer