Crusher Parts & Wear Components for Mining, Aggregate & Cement

Crusher parts encompass all wear and spare components for jaw crushers, cone crushers, HSI impact crushers, VSI crushers, gyratory crushers, and hammer mills. ATF manufactures high-performance jaw plates, mantles, concaves, blow bars, and rotor components in manganese steel grades (Mn13Cr2–Mn22Cr2), martensitic alloys, high-chrome iron, and TiC-reinforced composites. Our parts fit Metso, Sandvik, Terex, Kleemann, and 50+ other OEM brands, delivering 30–60% extended wear life in mining, aggregate, cement, and recycling operations. ISO 9001 certified with 35+ years manufacturing experience.

- 35+Years Experience

- 500+Global Customers

- 50+Countries Served

Premium Crusher Parts for All Equipment Types

ATF manufactures wear parts and spare components for all major crusher types serving the global mining, aggregate, cement, and recycling industries. Our comprehensive range covers jaw crushers, cone crushers, impact crushers, VSI crushers, gyratory crushers, and hammer mills.

Every part is manufactured using advanced metallurgy, precision casting, and rigorous quality control to ensure optimal fit, function, and durability in demanding applications. We specialize in high-wear components including jaw plates, cone mantles and concaves, blow bars, rotor tips, and liner assemblies.

⚡ Extended Service Life

Advanced materials and heat treatment processes deliver superior wear resistance compared to standard replacements. Typical improvements of 30–60% over conventional parts.

🔧 Perfect OEM Fit

Precision manufacturing ensures exact OEM specifications for proper installation and performance. Reverse-engineered to match original tolerances.

🌍 Global Compatibility

Parts engineered for all major equipment brands including Metso, Sandvik, Terex, Kleemann, and 50+ other manufacturers worldwide.

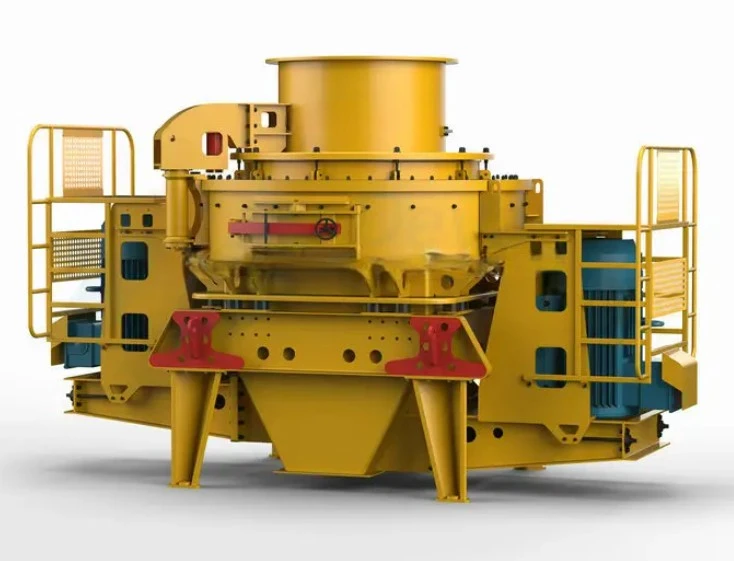

HSI Impact Crusher Parts

Premium blow bars, impact plates, and wear liners for horizontal shaft impactors. Optimized for limestone, concrete recycling, and soft to medium-hard materials in aggregate and recycling operations.

Key Applications

- Aggregate production and road building

- Concrete and asphalt recycling

- Limestone and dolomite processing

- Secondary and tertiary crushing stages

Available HSI Wear Parts

Impact Plates

Side Liners

Rotor Components

Curtain Chains

Material Options

Martensitic steel, high-chrome iron (Cr26–Cr28), and ceramic MMC (metal matrix composite) blow bars available. Material selection matched to feed material abrasiveness and impact energy requirements.

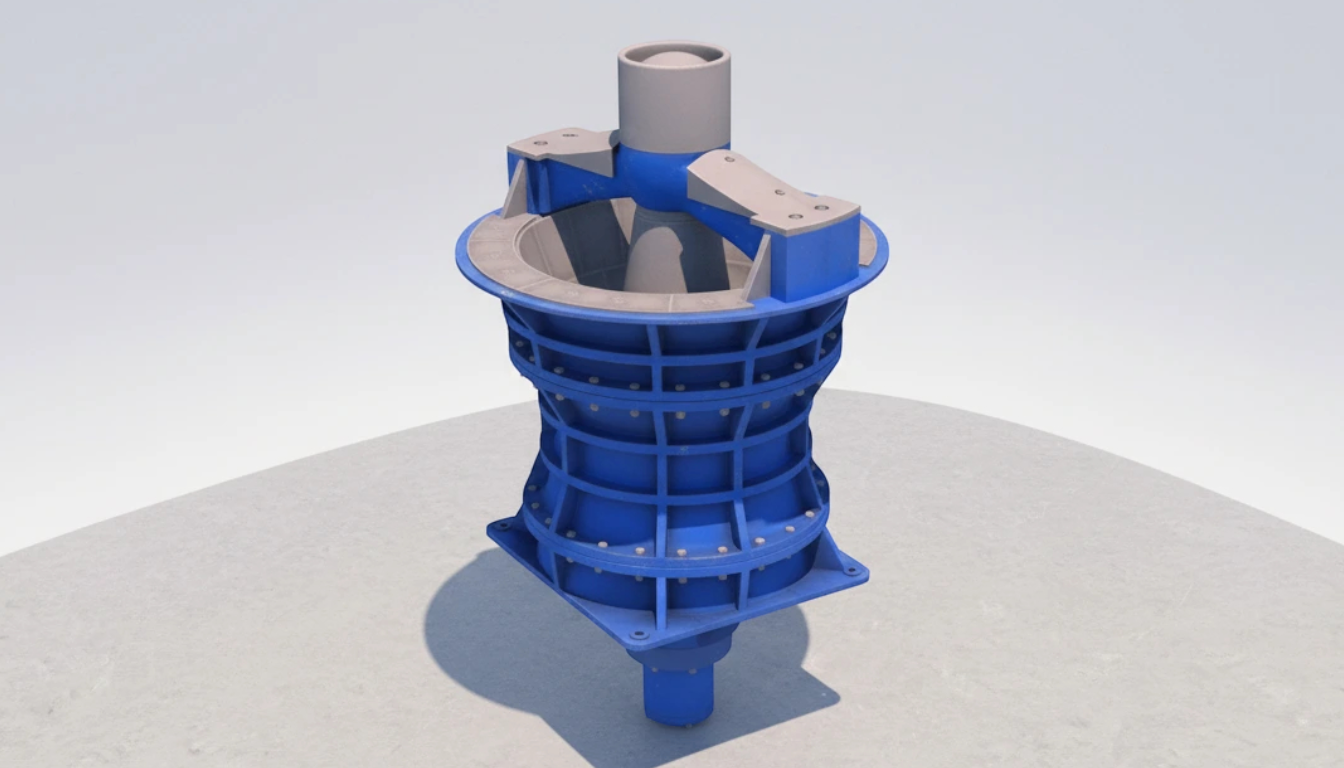

Cone Crusher Parts

High-performance mantles, concaves, and bowl liners for all cone crusher models. Designed for secondary and tertiary crushing of hard, abrasive materials with superior wear resistance through work-hardening manganese alloys.

Key Applications

- Hard rock mining operations (iron ore, copper, gold)

- Granite and basalt crushing

- Fine aggregate production

- Secondary and tertiary circuit optimization

Available Cone Wear Parts

Concaves

Bowl Liners

Feed Cones

Socket Liners

Material Options

Manganese steel grades Mn18Cr2 and Mn22Cr2 with optional TiC (titanium carbide) inserts for edge protection. Work-hardening alloys develop surface hardness up to 550 BHN under compression loading.

Jaw Crusher Parts

Durable jaw plates, cheek plates, and toggle components for primary crushing applications. Built to withstand extreme compressive forces and deliver consistent performance in heavy-duty mining and quarry operations.

Key Applications

- Primary crushing in mining circuits

- Quarry and stone processing

- Construction material preparation

- Large boulder reduction (ROM ore)

Available Jaw Wear Parts

Swing Jaw Plates

Cheek Plates

Toggle Plates

Side Liners

Material Options

Manganese steel grades Mn13Cr2 through Mn22Cr2 with standard, super-grip, and recycling tooth profiles. TiC edge reinforcement available for highly abrasive feeds.

Additional Crusher Types

We manufacture wear parts for VSI crushers, gyratory crushers, and hammer mills. Contact our technical team for specifications and availability.

🌪️ VSI Crusher Parts

Precision-engineered rotors, anvils, wear plates, and distribution plates for vertical shaft impactors. Specialized for manufactured sand production, aggregate shaping, and tertiary crushing applications.

Anvils

Wear Plates

🔄 Gyratory Crusher Parts

Heavy-duty mantles, concave segments, and spider components for large-scale gyratory crushers. Engineered for continuous high-volume primary crushing in mining operations processing 5,000+ TPH.

Concave Segments

Spider Caps

🔨 Hammer Mill Parts

Robust hammers, liner plates, grates, and breaker bars for hammer crushers. Optimized for crushing soft to medium-hard materials in cement raw material preparation and mineral processing.

Liner Plates

Grate Bars

OEM-Compatible Crusher Parts for Leading Equipment Brands

Our crusher wear parts are reverse-engineered to match OEM specifications. We manufacture aftermarket jaw plates, mantles, concaves, and blow bars for all major crusher brands worldwide.

All Brands

Don’t see your exact model? We reverse-engineer parts for virtually any crusher. Contact our engineering team with your equipment details for a custom solution.

Manufacturing Excellence

Every ATF crusher part is manufactured in our ISO 9001 certified facility using advanced metallurgy, precision casting, and comprehensive quality control processes.

🏭 Advanced Foundry Operations

State-of-the-art casting facilities with automated production lines, electric arc furnaces, and controlled cooling systems ensure consistent quality and dimensional accuracy across all production runs.

🔬 Metallurgical Expertise

In-house metallurgical laboratory with spectrometer analysis, hardness testing, and impact testing capabilities. We develop and validate specialized alloys including Mn13Cr2, Mn18Cr2, Mn22Cr2, and high-chromium iron compositions optimized for specific crushing applications.

✅ Quality Assurance

Rigorous chemical analysis, hardness testing, dimensional inspection, and visual examination at every production stage. Full traceability from raw material to finished product with heat number tracking.

35+ Years Experience

500+ Part Models

Complete Technical Support

Comprehensive support services to ensure optimal crusher performance and maximum part longevity throughout the equipment lifecycle.

🔧 Part Selection Guidance

- Application-specific material recommendations

- Wear life projections based on your feed material

- Cost-per-ton optimization analysis

📐 Custom Engineering

- Reverse engineering for obsolete or discontinued parts

- Custom profile designs for specific applications

- TiC insert placement optimization

🚚 Global Logistics

- Worldwide shipping with door-to-door delivery

- Expedited options for urgent requirements

- Customs documentation and export compliance

📞 Technical Assistance

- Installation guidance and best practices

- Troubleshooting support for wear issues

- Performance optimization recommendations

Industries We Serve

ATF crusher parts power operations across four major industry sectors, each with unique requirements for material selection and wear performance.

Mining & Quarrying

Engineered wear parts for high-tonnage operations in hard rock mining, iron ore, copper, gold, and aggregate extraction.

- Primary and secondary crushing circuits

- High-impact abrasive applications

- Extended service life in demanding conditions

Aggregates Production

Optimized crusher parts for consistent product gradation in sand, gravel, and crushed stone operations.

- Manufactured sand (M-sand) production

- Road base and construction aggregates

- Stable CSS for specification compliance

Recycling & C&D

Rebar-tolerant wear parts for concrete recycling, asphalt reclamation, and demolition waste processing.

- Concrete and demolition waste

- Asphalt and RAP processing

- Contamination-resistant designs

Cement Production

Reliable wear parts for continuous-duty limestone crushing in cement plants and lime operations.

- Limestone and cement raw materials

- Raw mix preparation crushing

- High-availability requirements

Crusher Parts – Frequently Asked Questions

Common questions about crusher wear parts, material selection, compatibility, and ordering.

What crusher types do you manufacture parts for?

We manufacture wear parts for all major crusher types used in mining, aggregate, cement, and recycling operations:

- Jaw Crushers: Fixed and swing jaw plates, cheek plates, toggle plates, side liners

- Cone Crushers: Mantles, concaves, bowl liners, feed cones, socket liners

- HSI Impact Crushers: Blow bars, impact plates, side liners, rotor components

- VSI Crushers: Rotors, anvils, wear plates, distribution plates

- Gyratory Crushers: Mantles, concave segments, spider caps

- Hammer Mills: Hammers, liner plates, grate bars, breaker bars

Are your parts compatible with OEM equipment?

Yes. Our parts are reverse-engineered to match OEM specifications for brands including Metso, Sandvik, Terex, Kleemann, Hazemag, McCloskey, Powerscreen, and many others. We ensure proper fit, mounting dimensions, and performance characteristics. Every part is manufactured to original tolerances with proper metallurgical specifications to deliver OEM-equivalent or better performance.

What materials are used in your crusher parts?

We use specialized alloys optimized for different crushing mechanisms and applications:

- Manganese Steel (Mn13Cr2, Mn18Cr2, Mn22Cr2): For jaw plates, cone liners, and other compression applications. Work-hardening alloys that develop surface hardness under impact.

- Martensitic Steel: For HSI blow bars processing clean, non-abrasive feeds like limestone and recycled concrete.

- High-Chrome Iron (Cr26–Cr28): For highly abrasive applications with lower impact requirements.

- TiC Composites: Titanium carbide inserts for edge protection in high-wear zones.

- Ceramic MMC: Metal matrix composites for impact applications requiring maximum abrasion resistance.

How long do your crusher parts typically last?

Service life varies significantly based on feed material characteristics, operating conditions, and crusher settings. As a general guide:

- Jaw Plates: 400–2,000+ hours depending on material hardness and feed size

- Cone Liners: 1,000–4,000+ hours depending on chamber selection and CSS

- Blow Bars: 400–3,000+ hours depending on material type and rotor speed

We provide estimated service life projections based on your specific application details. Our parts typically deliver 30–60% longer wear life compared to standard aftermarket alternatives.

Do you provide installation and maintenance support?

Yes. We provide comprehensive technical support including installation guidance, proper crusher settings recommendations, and maintenance procedures. Our engineering team can assist with troubleshooting wear issues, performance optimization, and material selection to maximize part life and crushing efficiency. Support is available via email, phone, and video call.

What is the typical lead time for crusher parts?

Lead times vary by part type, size, and quantity:

- Stock Items: 1–2 weeks (common blow bar and jaw plate sizes)

- Standard Production: 4–6 weeks

- Custom or Large Orders: 6–10 weeks

Expedited production and air freight options are available for urgent requirements. Contact us with your specific needs for accurate delivery estimates.

What information do you need for a quote?

To provide an accurate quote, we need:

- Equipment details: Crusher brand, model, and serial number if available

- Part identification: Part numbers, dimensions, or photos of existing parts

- Application context: Feed material type, production tonnage, current wear life

- Quantity: Number of sets or pieces required

- Delivery: Shipping destination and any time constraints

If you’re unsure about specifications, send photos and we’ll identify the correct parts for your equipment.

How do you ensure quality consistency?

Quality assurance is built into every production stage:

- Raw Materials: Certified steel suppliers with spectrometer verification of every heat

- Casting: Controlled pouring temperatures and cooling rates

- Heat Treatment: Process-controlled furnaces with temperature monitoring

- Inspection: Chemical analysis, hardness testing, dimensional verification, and visual examination

- Traceability: Full documentation with heat numbers and test certificates

Our ISO 9001 certified quality management system ensures consistent results across all production runs.

Get Your Custom Crusher Parts Quote in 24-48 Hours

Expert guidance for your crusher wear parts needs. No hassle, no sales pressure.

35+ years serving mining & aggregate operations

Prefer a different method?

Email: info@atfcs.com

Phone: +1 308 465 1950

Or visit our contact page

What Happens Next?

-

1

Instant Confirmation

You’ll receive an email confirmation immediately after submitting.

-

2

Expert Review

Our technical team analyzes your requirements and identifies optimal solutions.

-

3

Custom Quote

Receive comprehensive pricing within 24-48 business hours.

Serving aggregate, mining, cement & recycling industries globally.

OEM-compatible parts backed by ISO 9001 standards.

Your information is protected and never shared.

“ATF delivered exactly what we needed. Fast response, competitive pricing, and parts that lasted 30% longer than our previous supplier.”

— Operations Manager, Chilean Mining Company

Meet Our Leading HSI Wear Parts Engineering Experts

Our team of metallurgical and applications engineers is dedicated to optimizing your crushing performance and reducing your cost per ton. Connect directly with the minds behind ATF’s innovative blow bar solutions.

Bao Xiuru

Product Manager, HSI Wear Parts — 18+ years optimizing HSI blow bar alloys and designs for maximum wear life in aggregate & recycling plants. Specializes in cost-per-ton reduction strategies.

Zhang Lin

Senior Foundry Engineer, Metallurgy Specialist — Over 20 years of hands-on experience in the advanced casting and heat treatment of high-performance wear parts, focusing on metallurgical integrity and alloy innovation.