Premium Jaw Crusher Parts for Maximum Uptime

Complete wear and spare parts supply for all major jaw crusher brands. Engineered in premium manganese steel (Mn13–Mn22) with OEM-exact dimensions. From jaw plates to eccentric shafts—we stock everything to keep your crusher running at peak performance.

- 35+Years Experience

- 500+Global Customers

- 50+Countries Served

All Crusher Brands

Parts for Metso, Sandvik, Terex, Kleemann, Telsmith, and all major manufacturers

Complete Parts Range

From wear parts to critical mechanical components – everything in stock

Premium Materials

High manganese steel (Mn14Cr2 to Mn22Cr2) with full chemical analysis reports

Precision Engineering

CNC machined components with micron-level accuracy for perfect fit

Browse Jaw Crusher Parts by Category

Premium replacement parts engineered for maximum crusher performance and longevity

Jaw Plates

Premium austenitic manganese steel jaw plates in stationary (fixed) and movable (swing) configurations. Multiple tooth profiles available.

TiC Inserts

All Profiles

Cheek Plates

Upper and lower cheek plates providing critical sidewall protection. High-grade manganese steel with optimized profiles.

Side Protection

Toggle Assemblies

Complete toggle systems including plates, seats, and beams. Engineered as the crusher’s mechanical fuse for protection.

Cast Steel

Pitman Assemblies

Heavy-duty pitman assemblies in cast or fabricated steel. Provides reciprocating motion essential for crushing action.

CNC Machined

Eccentric Shafts

Precision-forged eccentric shafts from high-grade alloy steel. The heart of the jaw crusher converting rotational to reciprocating motion.

Heat Treated

Bearings & Seals

Premium crusher-duty spherical roller bearings and complete labyrinth seal systems from SKF, Timken, FAG.

Sealed Units

Frames & Housings

Structural steel frames and cast housings with precision-machined mounting surfaces. Non-welded construction.

Modular

Accessories & Hardware

Complete range of fastening systems, wedges, adjustment shims, compression springs, and specialized mounting hardware.

Complete Kits

Jaw Plates (Fixed & Movable Jaw Dies)

High-performance jaw plates engineered in Mn13–Mn22 austenitic manganese with optional TiC inserts. Optimized tooth profiles for aggregate, mining, recycling, and cement operations.

Overview & Function

Jaw plates are the primary wear components consisting of a fixed jaw plate mounted to the crusher frame and a movable jaw plate attached to the pitman. The crushing action occurs through compression between these surfaces.

Available Configurations

- Materials: Mn13, Mn18, Mn22 with optional TiC reinforcement

- Tooth Profiles: Standard Quarry, Super Grip, Flat/Non-Corrugated, Recycling

- Mounting: Bolt-on or wedge retention systems

- Brands: Metso, Sandvik, Terex, Powerscreen, Kleemann, McCloskey

Need Detailed Jaw Plate Selection Guidance?

Explore our comprehensive guide covering all manganese grades, tooth profiles, brand compatibility, CSS/nip angle tuning, and service life optimization strategies.

Cheek Plates (Side Liners)

Essential wear protection for crusher chamber sidewalls, preventing premature frame damage and extending equipment life.

High Manganese Construction

Manufactured from Mn14Cr2 to Mn18Cr2 alloys that work-harden under impact, providing extended service life in abrasive conditions.

Contoured Profile

Precision-profiled to match crushing chamber geometry, ensuring optimal material flow and uniform wear distribution.

Secure Mounting

Multiple mounting configurations available for bolt-on installation with precision-drilled holes matching OEM specifications.

Toggle Assemblies (Toggle Plates, Seats & Beams)

Critical safety and force transmission components protecting your crusher from damage due to uncrushable materials.

Toggle System Function

The toggle assembly serves dual purposes: transmitting crushing force from the pitman to the movable jaw, and acting as a mechanical fuse to protect the crusher when uncrushable material enters the chamber.

Complete Assembly Includes

- Toggle Plate (cast steel or cast iron)

- Pitman Toggle Seat (hardened steel)

- Frame Toggle Seat (hardened steel)

- Toggle Beam (cast/fabricated steel)

- Tension Rod & Springs

- Hardware Kit

Toggle Plate Types

Standard Cast Toggle

Single-piece casting designed to fracture cleanly when overloaded. Most economical for routine applications.

Two-Piece Shear Bolt

Calibrated shear bolts fail first, allowing quick field replacement without removing entire assembly.

Heavy-Duty Toggle

Reinforced design for applications with frequent overload conditions or larger feed with potential tramp iron.

Pitman Assemblies (Moving Jaw Assembly)

The heart of the jaw crusher’s crushing action – transferring eccentric shaft motion into crushing force.

Cast Pitman

One-piece casting – Traditional design offering excellent strength-to-weight ratio. Most common in modern crushers.

- Single-piece cast steel construction

- Integrated reinforcing ribs

- Reduced assembly complexity

- Excellent dimensional stability

- Minimal maintenance requirements

Fabricated Pitman

Welded steel plate assembly – Used in some older designs and special applications requiring field modification capability.

- Heavy steel plate construction

- Welded box-section design

- Internal reinforcement

- Repairable in some cases

- Custom fabrication possible

✓ Precision Machined

CNC machining of all critical surfaces to micron-level tolerances

✓ Premium Bearings

SKF, Timken, FAG branded bearings included in assembly

✓ 12-Month Warranty

Comprehensive coverage on materials and workmanship

Eccentric Shafts (Main Shaft)

The power transmission core – precision-forged from high-grade alloy steel to withstand extreme torsional and bending forces.

Manufacturing Excellence

Eccentric shafts are manufactured from high-carbon alloy steel (42CrMo4, 34CrNiMo6) and are always forged, never cast.

Process Steps

- Forging: Superior grain flow and elimination of internal voids

- Heat Treatment: Quenching and tempering for optimal hardness (280-320 HB)

- CNC Machining: Journal surfaces ground to Ra 0.8μm or better

- Balancing: Balanced to ISO 1940 Grade G6.3 or better

Quality Assurance

✓ Material Certification

Mill certificates for steel grade verification

✓ UT Inspection

Ultrasonic testing throughout shaft length

✓ MPI Testing

Magnetic particle inspection on ground surfaces

✓ Full Documentation

Complete dimensional and balance reports

Bearings & Sealing Systems

Premium bearing packages and advanced sealing systems ensuring reliable operation and extended component life.

SKF (Sweden)

Industry-leading quality. Explorer series for exceptional crusher performance.

Timken (USA)

Premium American-made bearings with outstanding reliability reputation.

FAG (Germany)

Precision German engineering with extensive crusher experience.

NSK / NTN (Japan)

High-quality Japanese bearings offering excellent value.

Bearing Types Available

- Spherical Roller Bearings

- Tapered Roller Bearings

- Cylindrical Roller Bearings

- Adapter Sleeves & Nuts

- Bearing Housings

- Complete Bearing Kits

Sealing Systems

- Multi-stage Labyrinth Seals

- V-Ring Seals

- Taconite Seals (Heavy-Duty)

- End Covers & Spacers

- Complete Seal Kits

Why Premium Bearings?

- 2-3x longer service life

- Lower operating temperatures

- Reduced vibration

- Better contamination resistance

- Manufacturer warranty

- Global technical support

Frames, Housings & Accessories

Major structural components and complete hardware range for crusher rebuild and maintenance projects.

Structural Components

- Complete crusher frames (cast/fabricated)

- Frame repair sections

- Bearing housings (pedestal type)

- Adjustment mechanisms & wedge blocks

- Guards & safety covers

- Chutes & hoppers with liners

Accessories & Hardware

- High-tensile fasteners (Grade 8.8, 10.9, 12.9)

- Drive components (pulleys, flywheels, belts)

- Adjustment wedges, shims, gauges

- Lubrication systems & fittings

- Wear protection (apron plates, liners)

- Specialized installation tools

Compatible with All Major Jaw Crusher Brands

We manufacture and supply parts for jaw crushers from all major OEMs worldwide

- C-Series: C63, C80, C96, C100, C105, C106, C110, C116, C120, C125, C130, C140, C145, C150, C160, C200

- LT-Series mobile: LT96, LT106, LT110, LT116, LT120, LT125, LT140, LT160

- Legacy models: NW, NP, ST series

- CJ-Series: CJ206-CJ860 (all models)

- JM-Series: JM806, JM907, JM1006, JM1107, JM1206, JM1312, JM1511

- QJ-Series mobile: QJ240, QJ241, QJ340, QJ341

- JW Series: JW30, JW40, JW42, JW50, JW55

- Pegson: 600×400, 750×500, 900×650, 1000×800, 1200×900

- Brown Lenox: KK Series

- Premiertrak mobile models

- T-Series: T300, T400, T500, T900, T1100

- Titan Series

- Jaw King models

- MOBICAT Series: MC 100, MC 110, MC 120, MC 125

- All mobile jaw crusher models

- Stationary models

Other Major Brands

- McCloskey (J & R Series)

- Powerscreen (Premiertrak)

- Finlay (J-Series)

- Komatsu / Extec

- Parker, Eagle, Trio, KPI-JCI

- Keestrack, Tesab, Hartl

- Chinese: Shanbao, SBM, Liming, Zenith, Hongxing

Don’t see your crusher model listed? We can manufacture parts for virtually any jaw crusher. Contact us with your crusher make, model, and part numbers for a quote.

Premium Materials & Quality Assurance

All jaw crusher wear parts manufactured from certified high-manganese steel with full quality documentation.

Manganese Steel Grades

We supply jaw plates and wear parts in four standard manganese grades:

- Mn13Cr2: Standard grade for moderate impact applications

- Mn14Cr2: Most common all-around grade

- Mn18Cr2: High impact and severe abrasion

- Mn22Cr2: Maximum wear resistance

Manganese steel work-hardens under impact—surface hardness increases from 200 HB as-cast to 400-500 HB in service.

Quality Control Process

1. Material Verification

Mill certificates and chemical composition verification

2. In-Process Inspection

Critical dimensions checked during operations

3. Heat Treatment Control

Temperature monitoring and time recording

4. NDT Testing

Ultrasonic and magnetic particle inspection

5. Final Inspection

100% dimensional verification

6. Documentation

Complete quality package with certifications

Certifications & Standards

- ISO 9001:2015 – Quality management certification

- ASTM Standards – Material specifications compliance

- EN Standards – European material and testing standards

Jaw Crusher Parts Gallery

Complete range of wear components for jaw crushers

Troubleshooting — Read the Wear Pattern

Common jaw liner wear signatures and recommended actions

❌ Top Third Worn Faster

Likely Cause: Open CSS / poor nip angle / uneven feed distribution

Recommended Action: Reduce CSS, improve feed presentation, consider deeper tooth profile

⚠️ Tooth Rounding / Scalloping

Likely Cause: Abrasive fines; inadequate tooth hardness for material

Recommended Action: Upgrade to Mn + TiC reinforcement; adjust CSS to maintain nip angle

📍 Center Localized Wear

Likely Cause: Material bridging / slabby feed characteristics

Recommended Action: Improve scalping operation; consider super-tooth or slab-breaker profile

🔧 Cracking / Chipping

Likely Cause: Tramp metal contamination / mis-seated plates / improper torque

Recommended Action: Improve metal detection; verify seating & torque; prefer higher Mn grade

Frequently Asked Questions

What information do I need to order jaw crusher parts?

We need your crusher make (Metso, Sandvik, etc.), model number (C110, CJ411, etc.), and ideally the OEM part numbers for the components you need. If you don’t have part numbers, photos and measurements can help us identify the correct parts.

Are your parts compatible with OEM equipment?

Yes, our parts are manufactured to meet or exceed OEM specifications. They are direct replacements and will fit and function exactly like original parts. We provide 100% dimensional accuracy guarantee.

What is the typical lead time for jaw crusher parts?

Stock items ship within 1-3 business days. Standard wear parts (jaw plates, cheek plates) typically 2-4 weeks. Major components (pitman, eccentric shaft) 6-12 weeks. We offer expedited service for critical needs.

Do you offer warranties on your parts?

Yes, all our parts come with a manufacturer’s warranty covering defects in materials and workmanship. Wear parts: 3-6 months depending on application. Mechanical components: 12 months standard.

Can you supply parts for older or discontinued crusher models?

Absolutely. We have extensive reverse-engineering capabilities and can manufacture parts for obsolete models. We may need to inspect your existing parts or crusher to ensure perfect fit.

What documentation do you provide with parts?

We provide material certificates (mill certs), heat treatment reports where applicable, dimensional inspection reports, and packing lists. Additional documentation available upon request.

Do you ship internationally?

Yes, we ship worldwide. We have experience with international logistics and can arrange delivery to any location. We handle all export documentation and can ship via air or sea freight.

Can you help with installation and technical support?

Yes, we provide technical support for all our parts including installation guidance, troubleshooting assistance, and maintenance recommendations. Field service support can be arranged for major installations.

How long do jaw plates typically last?

Jaw plate service life varies significantly by application. Soft limestone/dolomite may see 2,000-4,000 hours with Mn13 or Mn18. Hard granite/basalt typically delivers 800-2,000 hours with Mn18 or Mn22. River gravel ranges 1,200-3,000 hours depending on silica content. Concrete recycling sees 600-1,500 hours with proper tooth profile. Iron ore typically achieves 500-1,200 hours with Mn22 + TiC inserts.

These estimates assume proper CSS settings, choke feed conditions, and regular inspection. See detailed service life guide →

What causes premature jaw plate wear?

Common causes include: tooth polishing from fines (pre-screen to remove -10mm material), open CSS operation reducing crushing force, one-side feed creating uneven wear, wrong alloy selection for rock type, and poor seating preventing work-hardening. See our troubleshooting guide for detailed diagnostics.

Which jaw plate tooth profile should I use?

Tooth profile selection depends on your feed and application. Standard/Corrugated is most versatile for general quarrying. Super Grip/Deep Tooth works best for large, irregular, slabby feed. Flat/Non-Corrugated suits soft rock and controlled gradation. Recycling Profile handles concrete/asphalt with rebar. View complete tooth profile guide →

What are the advantages of TiC-reinforced jaw plates?

TiC (Titanium Carbide) inserts provide edge protection in highly abrasive applications: extended edge life (1.5-2× longer than plain manganese), CSS stability through slower tooth rounding, optimal load distribution, and cost effectiveness in siliceous feeds. Best for iron ore, hard granite, quartzite, siliceous gravel. Not recommended for heavy tramp metal risk or recycling with rebar.

How do I choose between Mn13, Mn18, and Mn22 jaw plates?

Select based on rock hardness and abrasiveness. Mn13 (12-14% Mn) suits softer rock like limestone. Mn18 (17-19% Mn) is the most popular grade for granite, basalt, river rock. Mn22 (20-24% Mn) is for very hard, abrasive rock like iron ore. Rule of thumb: start with Mn18 for general quarrying. Detailed material selection guide →

Can jaw plates be rebuilt or refurbished?

Manganese jaw plates can sometimes be rebuilt through hardfacing, but with limitations. Rebuilding works when plates have adequate remaining thickness (>50% original), no cracks, and proper tooth form still visible. However, rebuilt sections don’t work-harden like original cast manganese, and subsequent wear life is typically 40-60% of new plates. Replacement is usually more economical for small-medium crushers.

What installation mistakes cause jaw plate failures?

Common installation errors include: poor seating (gaps behind plate), incorrect torque (over/under-torquing), dirty mounting surfaces, mismatched profiles on fixed vs. movable jaw, and no re-torque after warm-up. Always verify <0.5mm gaps with feeler gauges, follow OEM torque specs, and re-torque after 1-2 hours of operation.

How do I calculate cost per ton for jaw plates?

Cost per ton = (Plate set cost + Installation labor + Downtime cost) ÷ Tons processed. Include all costs: purchase price, crew hours for installation, and lost production during changeout. Premium alloys (Mn22 + TiC) cost more upfront but often deliver lower cost/ton through extended life. Focus on cost per ton, not purchase price alone.

Get Your Custom Quote in 24-48 Hours

Expert guidance for your jaw crusher parts needs. No hassle, no sales pressure.

35+ years serving mining & aggregate operations

Prefer a different method?

Email: [email protected]

Phone: +1 308 465 1950

What Happens Next?

-

1

Instant Confirmation

You’ll receive an email confirmation immediately

-

2

Expert Review

Our technical team analyzes your requirements

-

3

Custom Quote

Receive detailed pricing within 24 hours

Serving aggregate, mining & cement industries

OEM-compatible parts with technical support

Your information is protected and never shared

“ATF delivered exactly what we needed. Fast response, competitive pricing, and parts that lasted 30% longer than our previous supplier.”

— Operations Manager, Chilean Mining Company

Meet Our Jaw Crusher Parts Engineering Experts

Our team of metallurgical and applications engineers is dedicated to optimizing your primary crushing performance and reducing your cost per ton.

Bao Xiuru

Product Manager — 18+ years optimizing jaw plate alloys and corrugation profiles for mining & quarrying operations.

Zhang Lin

Senior Foundry Engineer — Over 20 years of hands-on experience in the advanced casting and heat treatment of manganese steel jaw plates.

Industries We Serve

Mining & Quarrying

Engineered wear parts for high-tonnage operations in hard rock mining, iron ore, copper, and gold extraction.

Aggregates Production

Optimized crusher parts for consistent product gradation in sand, gravel, and crushed stone operations.

Recycling & C&D

Rebar-tolerant wear parts for concrete recycling, asphalt reclamation, and demolition waste processing.

Cement Production

Reliable wear parts for continuous-duty limestone crushing in cement plants and lime operations.

Complete Your Crushing Circuit

Browse our full range of crusher wear parts

Jaw Crusher Plates

Detailed specifications, material options, and tooth profile selection for fixed and swing jaw plates.

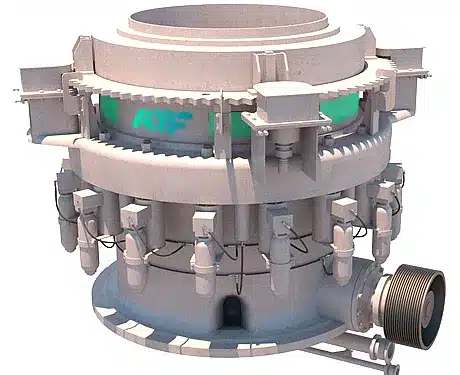

Cone Crusher Liners

Mantles and concaves for secondary and tertiary crushing applications.

HSI Blow Bars

Impact crusher blow bars for aggregate, recycling, and manufactured sand applications.