High-Performance Blow Bars for HSI Impact Crushers

ATF-engineered HSI blow bars consistently demonstrate a quantifiable 2–4× extension in operational wear life in rigorously controlled applications, directly reducing cost-per-ton and extending Mean Time Between Failure (MTBF). This is achieved through precision metallurgy, specifically optimized for diverse duty cycles including concrete recycling, high-abrasion aggregate production, engineered sand manufacturing, and demanding quarrying operations. We offer advanced alloys like manganese steel, martensitic steel, high chrome white iron, and cutting-edge ceramic insert Metal-Matrix Composite (MMC) blow bars. Our parts are compatible with leading brands such as Metso NP-Series, Sandvik QI, Powerscreen Trakpactor, Kleemann MOBIREX, McCloskey, and over 50 other manufacturers.

- 35+Years Experience

- 500+Global Customers

- 50+Countries Served

Selecting Optimal Blow Bars: Our Advanced Alloy Range

Select the optimal metallurgy, precisely engineered for your specific duty cycle and crushing chamber. Each option includes detailed specifications and practical application guidance.

Manganese 18% (ASTM A128 Grade C Equivalent)

Superior balance of wear resistance and extreme toughness for primary impact applications.

Hardness: HB 200-240 (work-hardens to HB 550+)

Chemistry: C 1.1-1.4%, Mn 17-19%, Cr 1.7-2.3% (ASTM A128 Grade C Equivalent)

Impact Strength: Very High (>300 J/cm²)

Typical Life: 130,000 tons (20-30% longer than Mn13 in aggressive applications)

Manganese + Titanium Carbide (TiC) Inserts (ASTM A128 Grade C Equivalent)

Combines manganese toughness with extreme TiC edge reinforcement for enhanced abrasion resistance.

Hardness: HB 200-240 base (work-hardens to 550+ HB) + HV 3200 TiC inserts

Chemistry: Mn base: C 1.1-1.4%, Mn 17-19% (ASTM A128 Grade C Equivalent); TiC rods precision cast-in.

Impact Strength: Very High (>300 J/cm² base)

Typical Life: 800-1,400 hours (30-50% longer than plain manganese in abrasive conditions)

ATF Martensitic Steel Blow Bars (e.g., DIN 1.2704 / ASTM A536 Equivalent)

Engineered for a balanced blend of high abrasion resistance and superior impact tolerance.

Hardness: 48-54 HRC

Chemistry: Low-alloy steel, meticulously quenched & tempered for optimal microstructure.

Impact Strength: Medium-High (100-300 J/cm²)

Typical Life: 400-700 hours in concrete recycling (with moderate rebar)

ATF Martensitic + Ceramic Inserts (DIN 1.2704 / ASTM A536 Equivalent Matrix)

Engineered for a quantifiable 2–4× life extension versus conventional mono-alloys, these Metal-Matrix Composite (MMC) blow bars are specifically optimized for demanding concrete and asphalt recycling operations, minimizing cost-per-ton.

Hardness: 48-54 HRC base (matrix) + HV 1600 (ceramic inserts)

Chemistry: Martensitic steel matrix with precisely cast-in ceramic tiles.

Impact Strength: Medium (50-150 J/cm²), optimized for controlled shock loads.

Typical Service Life: 800-1,600 hours in concrete recycling; 1,000-1,800 hours in asphalt recycling (under controlled feed conditions).

High Chrome Blow Bars (ASTM A532 Class III Type A Equivalent)

Engineered for maximum hardness and wear resistance in clean, highly abrasive feeds.

Hardness: 60-64 HRC white iron

Chemistry: C 2.5-3.5%, Cr 24-28% (ASTM A532 Class III Type A Equivalent)

Impact Strength: Very Low (~10 J/cm²)

Typical Life: 800-1,500 hours in limestone; 600-1,200 hours in mixed aggregates (clean feed)

High Chrome + Ceramic Inserts (ASTM A532 Class III Type A Equivalent Matrix)

Unmatched abrasion resistance for clean, low-impact secondary duty, providing maximum wear life.

Hardness: 60-64 HRC + HV 1600 ceramic

Chemistry: High-chrome white iron matrix (ASTM A532 Class III Type A Equivalent) with precision ceramic inlays.

Impact Strength: Very Low (~10 J/cm²)

Typical Life: 1,200-2,400 hours in clean asphalt; 1,500-2,500 hours limestone secondary

High Chrome + Ceramic Plus (ASTM A532 Class III Type A Equivalent Matrix)

Features extended ceramic insert coverage for the absolute maximum service life in ultra-abrasive applications.

Hardness: 60-64 HRC + extended ceramic coverage (up to 60mm depth)

Chemistry: High-chrome white iron (ASTM A532 Class III Type A Equivalent) with deeper/wider ceramic inserts.

Impact Strength: Very Low (~10 J/cm²)

Typical Life: 1,500-3,000 hours clean limestone; up to 2,400 hours manufactured sand

High Chrome (Lower Hardness) Blow Bars (ASTM A532 Class III Type B Equivalent)

Heat-treated for significantly improved toughness and fracture resistance, ideal for variable conditions.

Hardness: 55-58 HRC (vs. 60-64 HRC standard)

Chemistry: C 2.5-3.5%, Cr 24-28%, precisely heat-treated for enhanced toughness (ASTM A532 Class III Type B Equivalent).

Impact Strength: Low-Medium (20-50 J/cm²)

Typical Life: 1,000-1,800 hours in mixed aggregates with occasional impacts

High Chrome (Lower Hardness) + Ceramic Inserts (ASTM A532 Class III Type B Equivalent Matrix)

Combines enhanced tempered toughness with ceramic edge protection for superior all-round performance.

Hardness: 55-58 HRC base + HV 1600 ceramic

Chemistry: Tempered high-chrome white iron matrix (ASTM A532 Class III Type B Equivalent) with ceramic inserts.

Impact Strength: Low-Medium (20-50 J/cm² base)

Typical Life: 1,200-2,000 hours in mixed aggregates with controlled steel removal

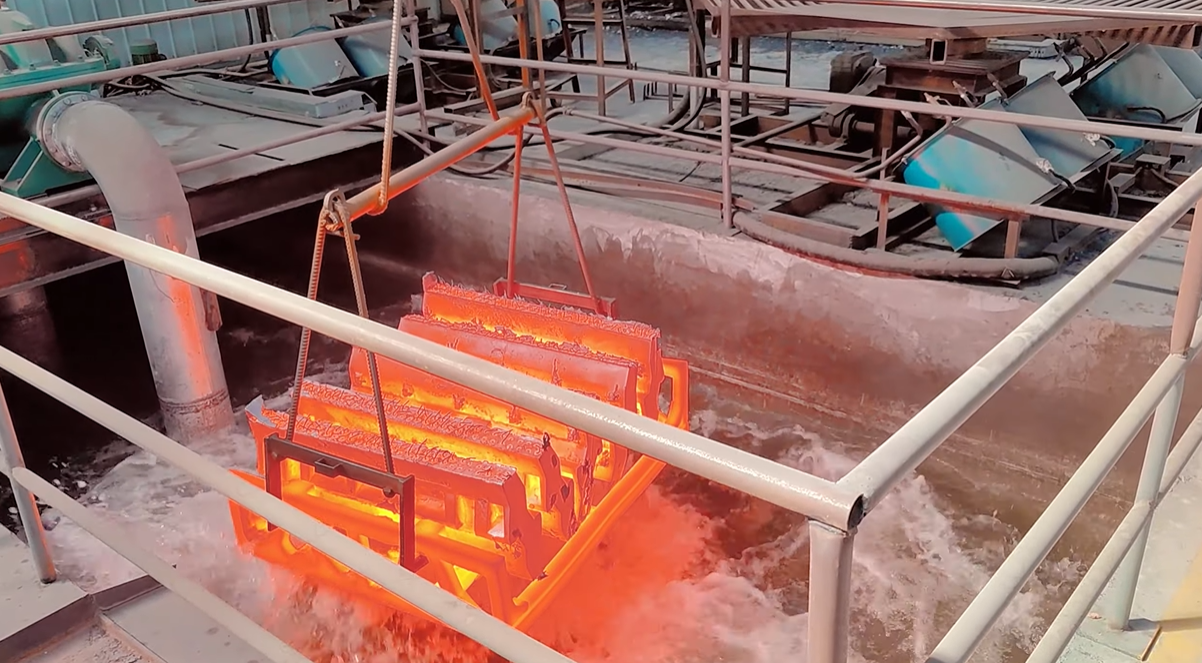

Precision Blow Bar Manufacturing Gallery

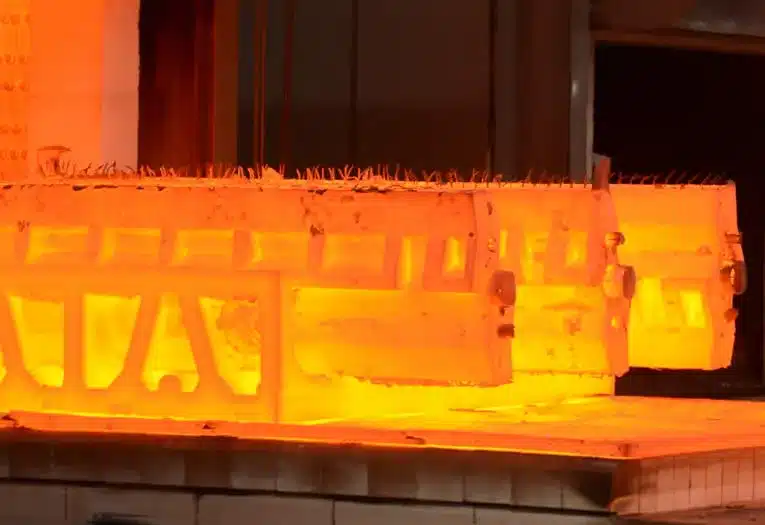

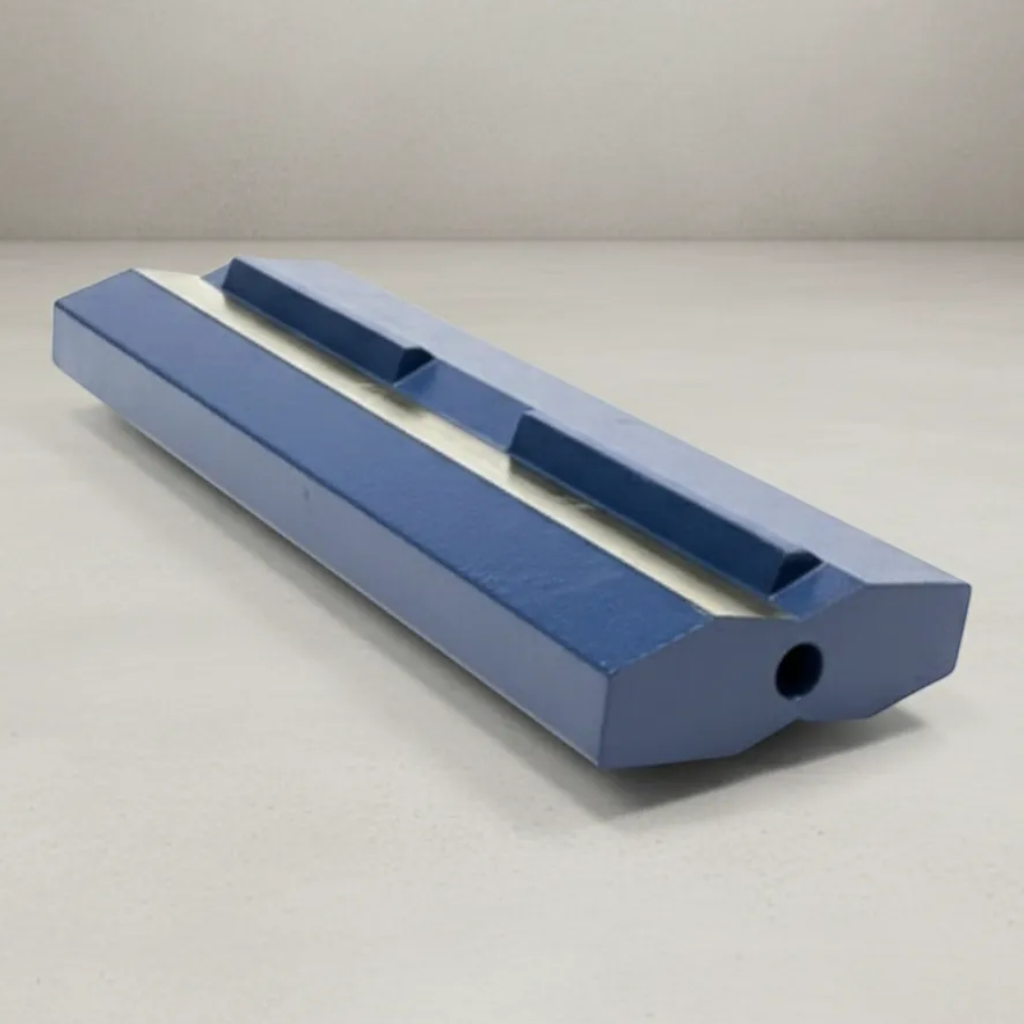

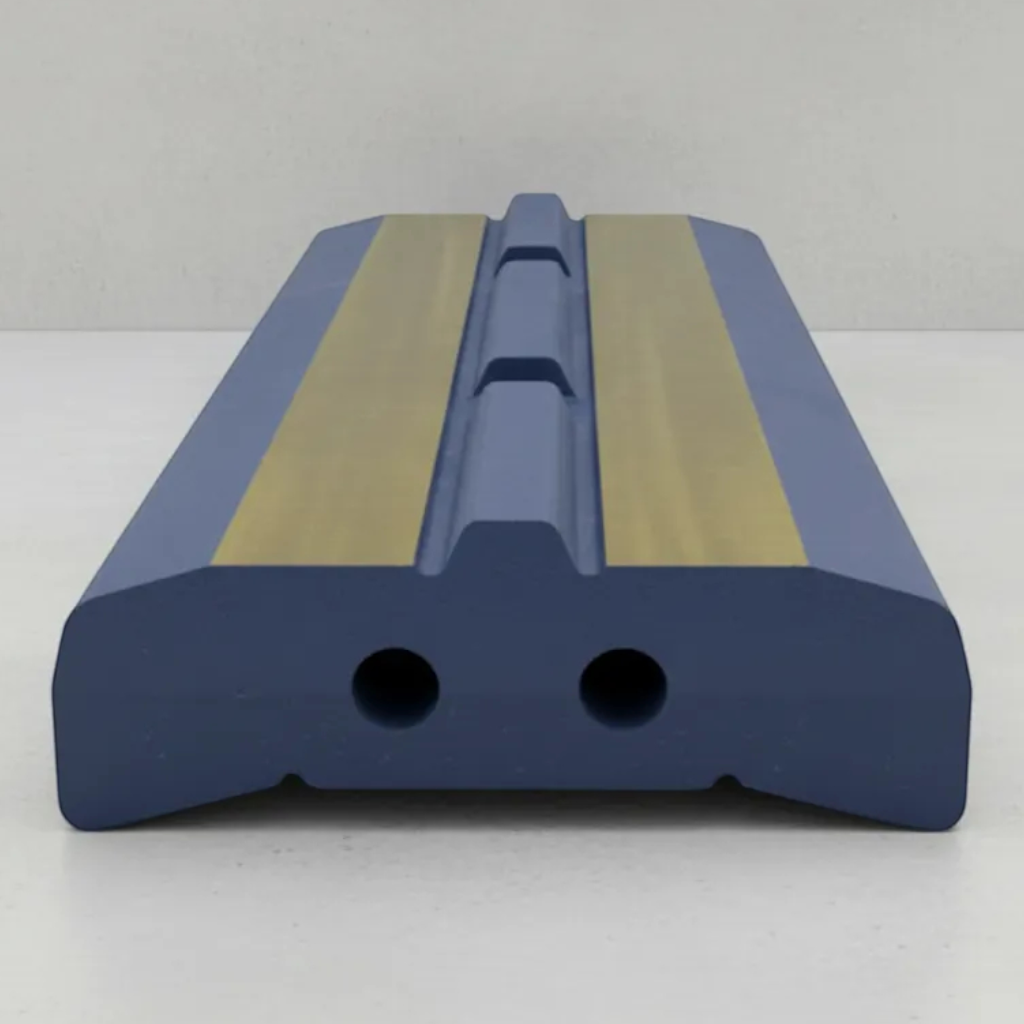

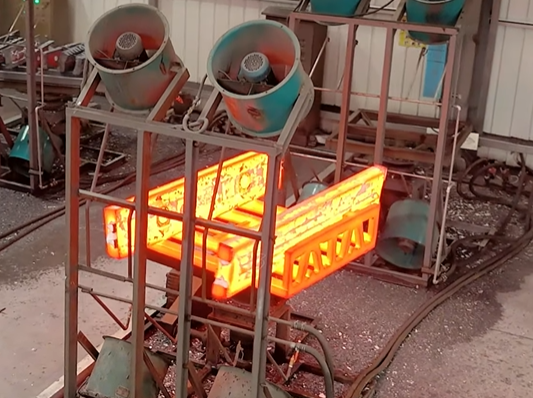

See our rigorous processes: advanced casting, controlled heat treatment, precise finish machining, and stringent quality control.

-

ATF Foundry heat treatment -

Manganese blow bar — Grinding -

Martensitic Ceramic HSI blow bar -

High Chrome + Ceramic HSI blow bar -

Manganese blow bar profile -

Manganese + TiC composite blow bar -

Martensitic blow bar overview -

High Chrome + Ceramic inlays -

Manganese + TiC edge detail -

High Chrome (Lower Hardness) blow bar -

Martensitic ceramic blow bar -

High Chrome Ceramic blow bar -

High Chrome Blow bars -

High Chrome Blow bars -

High Chrome Blow bars

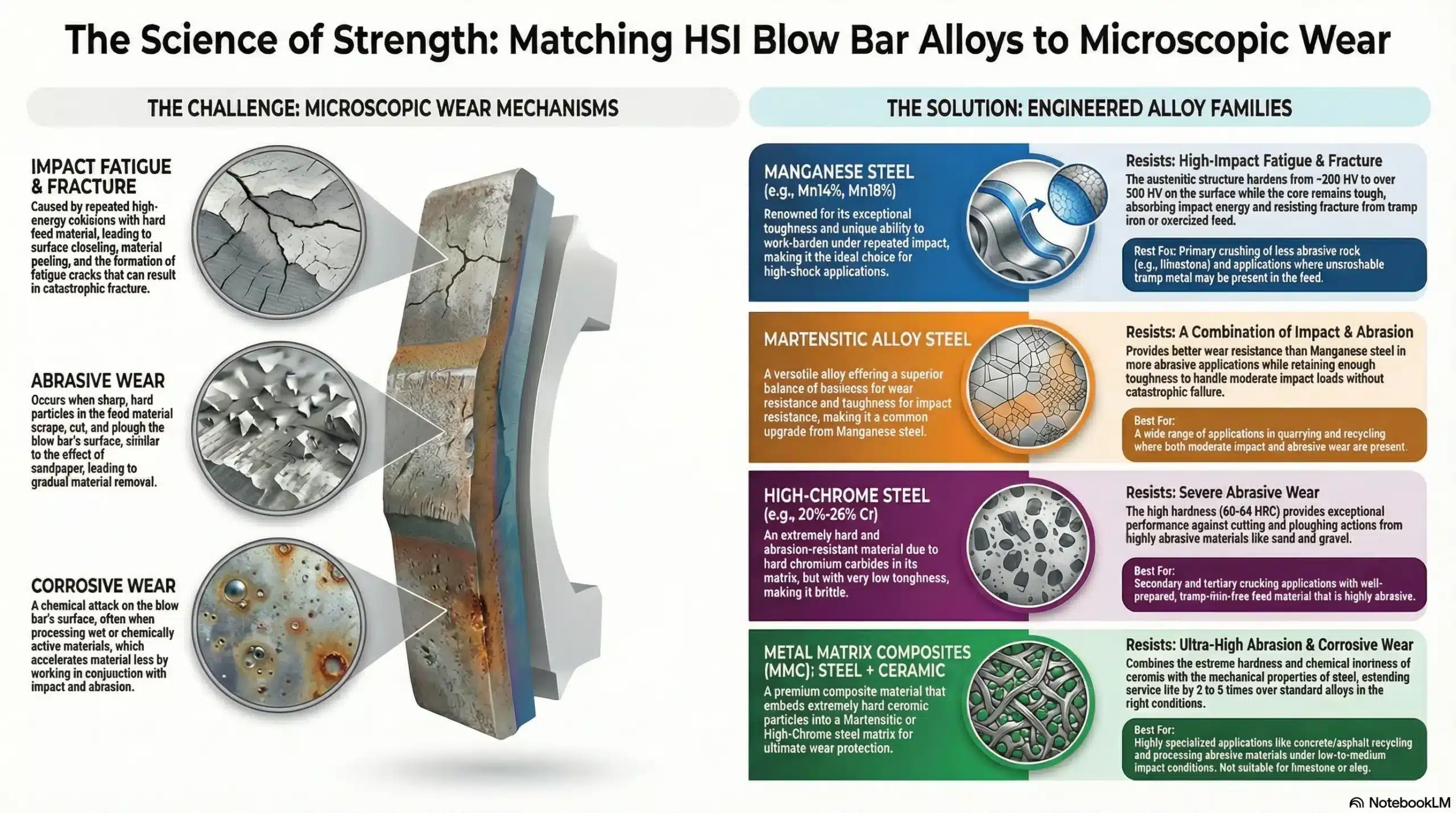

Unlocking Performance: Advanced Wear Science & Metallurgy for HSI Blow Bars

Understanding microscopic wear mechanisms is crucial for optimizing HSI blow bar performance and cost-per-ton. Our proprietary alloys are engineered to counter specific challenges in your crushing environment.

Selecting the optimal HSI blow bar requires a strategic balance of impact vs. abrasion resistance, understanding your expected feed material size and characteristics, and accurately assessing tramp-metal (rebar) risk. Fine-tune your operational efficiency by adjusting rotor speed and curtain gaps (S1/S2) to achieve your target cost per ton and desired product gradation. We integrate deep knowledge of specific wear mechanisms, including micro-abrasion, galling, and spalling fatigue, into our alloy development.

Feed Material Factors

- Top size: Large/variable feed demands tougher alloys (Manganese, Mn+TiC, Martensitic) to prevent catastrophic failure.

- Abrasiveness: High-silica aggregates, manufactured sand, or asphalt = high abrasion. High-chrome + ceramic excels when mechanical shocks are consistently low, mitigating micro-abrasion.

- Fines content: Excessive fines act like sandblasting, accelerating wear. Pre-screen to reduce needless wear and optimize specific energy consumption.

- Moisture: Use only necessary water for dust control; avoid slurry conditions inside the chamber, which can exacerbate erosion corrosion and sticky material buildup.

Crusher Operational Factors

- Curtain gaps (S1/S2): Tighter settings yield finer product and increase load/wear; wider settings produce coarser material and reduce wear. Optimizing CSS is key.

- Rotor speed: Higher RPM increases fines and wear rate exponentially; lower RPM reduces wear but increases oversize. Match speed to desired product shape index (PSI) and alloy capabilities.

- Geometry: Maintain symmetrical settings across impact curtains to prevent uneven wear patterns and rotor imbalance in your HSI impact crusher blow bars.

| Rotor Tip Speed | Wear Rate | Fines Production | Oversize Product | Specific Energy Consumption |

|---|---|---|---|---|

| Lower | ↓ | ↓ | ↑ | ↓ |

| Higher | ↑ | ↑ | ↓ | ↑ |

Maintenance & Control Factors

- Centered, consistent feed promotes rock-on-rock buffering, reduces direct blow bar impact, and ensures even wear distribution.

- Rigorous tramp-metal control (magnets, picking stations, metal detectors) is critical to prevent sudden fracture in brittle high-chrome white iron families.

- Rotation/flip schedule: Implement a proactive maintenance schedule to flip or rotate blow bars before reaching their wear-limit, preventing costly rotor damage and ensuring stable product quality.

- Foundry Processes: Our strict quality control includes solution annealing, quenching, and tempering profiles optimized for each alloy to ensure metallurgical integrity.

| Alloy Family | Impact Tolerance | Abrasion Resistance | Feed Size Fit | Tramp/Rebar Tolerance | Best For | Avoid If | Inserts / Upgrade | Typical Standard Equiv. |

|---|---|---|---|---|---|---|---|---|

| Manganese (Mn) | Very High | Low–Medium | Large | High | Primary crushing, variable/unknown feed, high tramp-iron risk; ideal as aftermarket blow bars for Metso NP1315 | Clean, very abrasive secondary/tertiary applications | TiC optional (edge retention) | ASTM A128 Grade C |

| Manganese + TiC | Very High | Medium | Large–Medium | High | Primary or heavy demolition where plain Mn wears fast; improved edge life; suitable as aftermarket blow bars for Metso NP1620 | Ultra-clean, highly abrasive secondary duty with minimal impact | Integrated TiC rods | ASTM A128 Grade C Equivalent |

| Martensitic | Medium–High | Medium–High | Medium | Medium | Concrete recycling, mixed demolition, asphalt reclamation, moderate rebar; often used as aftermarket blow bars for Kleemann MR130 | Extreme primary shocks or frequent large unbreakables (fracture risk) | Ceramic optional (2–4× life in clean duty) | DIN 1.2704 / ASTM A536 Equivalent |

| Martensitic + Ceramic | Medium | High | Medium–Small | Low–Medium (controlled) | Recycling with screened feed; cleaner quarry feeds; enhanced wear life; a high-performance alternative for Sandvik QI442 wear parts | High tramp-metal or very large feed shocks (ceramic spalling risk) | Ceramic inlays for edge retention | DIN 1.2704 / ASTM A536 Equivalent Matrix |

| High Chrome | Low | Very High | Small | Low | Clean secondary stone/asphalt; controlled feed; minimal steel; high abrasion; a cost-effective choice for Metso NP1213 blow bars | Rebar/tramp metal or primary shocks (brittle fracture risk) | Upgrade to Ceramic / Ceramic Plus | ASTM A532 Class III Type A |

| High Chrome + Ceramic | Low | Max | Small | Low | Very abrasive, clean secondary/tertiary; manufactured sand; longest life; excellent for Tesab blow bars in clean applications | Any meaningful tramp-iron risk or high shock loads (ceramic spalling) | Ceramic inlays; 2–4× life in right duty | ASTM A532 Class III Type A Matrix |

| High Chrome + Ceramic Plus | Low | Max | Small | Low | Ultra-abrasive, clean secondary with tight feed control; extreme wear life; often outperforms Xwin blow bars in specific conditions | Primary shocks or any tramp-iron presence (ceramic failure) | Deeper/wider insert coverage; longest edge retention | ASTM A532 Class III Type A Matrix |

| High Chrome (Low Hardness) | Medium | High | Medium | Low–Medium | Medium-to-abrasive feeds with occasional impact shocks; variable quarry; a robust option for I44 blow bars | Ultra-abrasive, very clean feeds where max hardness is paramount | Tempered for added toughness | ASTM A532 Class III Type B Equivalent |

| High Chrome (Low Hardness) + Ceramic | Medium | High–Very High | Medium–Small | Low–Medium (controlled) | Abrasive feeds with some variability but limited tramp; balanced performance; a high-performance choice for I54 blow bars | Primary / very high shock duty (Martensitic or Manganese preferred) | Tempered matrix + ceramic inserts | ASTM A532 Class III Type B Equivalent Matrix |

Precision Machining & Fit: Pre-Installation Inspection

- Ensure seating faces are meticulously flat & fully supported; no light under a precision straight edge to prevent uneven loading.

- Verify positive noses/locators correctly engage rotor pockets; no rocking or lateral movement after installation.

- Confirm uniform section thickness—avoid deep grooves that compromise structural support under dynamic load and prevent spalling.

- Adhere to strict pocket fit & wedge torque specifications; perform re-check after initial warm-up (thermal expansion).

- Request Quality Documentation: Demand machining flatness reports, dimensional inspection certificates, and hardness maps to verify compliance.

Ceramic & TiC Composites: Maximize ROI with MMC

In clean, low-shock applications where abrasion is the dominant wear mechanism, advanced ceramic or TiC Metal-Matrix Composites (MMC) can deliver a proven 2–4× longer operational life versus mono-alloys. This translates directly to fewer change-outs, reduced labor costs, more consistent product shape index, and a significantly lower cost per ton. This also applies to aftermarket Metso NP1213 blow bars and Sandvik QI442 wear parts equivalent when properly selected.

Critical Note: If tramp-iron or rebar risk isn’t near zero, prioritize a tougher matrix alloy such as Martensitic steel or Manganese steel. Ceramic will not tolerate high impact from uncrushables.

Decision Matrix: Selecting Optimal HSI Blow Bars for Your Operation

Utilize our expert matrix to quickly identify the optimal blow bar metallurgy for your specific application. For personalized recommendations, try our Interactive Selector or Request a Technical Review.

High Tramp Metal / Large, Variable Feed (Primary Crushing)

Start: Manganese (Mn18Cr2) for maximum impact tolerance. → Upgrade: Manganese + TiC if manganese wears too fast and some abrasion needs addressing. Maximum (with feed control): Martensitic steel for balanced performance.

Prioritize highest impact tolerance and rebar/tramp metal resilience. TiC inserts improve edge retention without sacrificing significant toughness. Ideal for primary applications with high tramp metal risk, such as those typically requiring Metso NP1620 blow bars.

Concrete Recycling / Mixed Demolition (Moderate Rebar)

Start: Martensitic Steel for its superior balance of hardness and toughness. → Upgrade: Martensitic + Ceramic for 2–4× wear life when tramp metal is reliably controlled and abrasion dominates.

Offers balanced hardness & toughness; ceramic delivers extended life and reduced cost per ton when tramp is minimized. Excellent for applications often needing Kleemann MR130 aftermarket blow bars.

Clean Secondary Stone / Asphalt (Small, Controlled Feed)

Start: High Chrome for high abrasion resistance. → Upgrade: High Chrome + Ceramic. → Maximum Wear Life: High Chrome + Ceramic Plus for ultimate performance.

Engineered for very high abrasion resistance when steel is completely removed and impact loads are consistently low. Optimizes product shape index. Commonly used as Tesab blow bars or aftermarket Sandvik QI442 wear parts in ideal conditions.

Variable Quarry Conditions (Mostly Clean, Occasional Shocks)

Start: High Chrome (Lower Hardness) for improved toughness. → Add: High Chrome (Lower Hardness) + Ceramic if abrasion is the primary wear mechanism.

Tempered matrix strategically trades a small percentage of hardness for significantly enhanced toughness to handle intermittent impact shocks without fracturing. A resilient choice for I44 blow bars in challenging environments.

Highly Abrasive Feed (Silica, Manufactured Sand, Basalt)

Start: High Chrome + Ceramic for superior edge retention. → Maximum Performance: High Chrome + Ceramic Plus for the longest operational life.

Deep and wide ceramic coverage delivers unparalleled edge retention and resistance to micro-abrasion in low-shock, high-abrasion duties. Significantly reduces cost per ton.

Rebar or Tramp Metal Cannot Be Fully Avoided

Absolute Choice: Prioritize Manganese or Martensitic steel alloys. It is critical to avoid high-chrome white iron families unless steel is reliably and consistently removed from the feed stream.

High-chrome white iron (including ceramic composites) is inherently fracture-prone under mechanical shock or direct tramp metal impacts, leading to premature blow bar failure and potential rotor damage. This guidance is critical for concrete recycling blow bars and asphalt recycling blow bars where tramp metal is a constant threat.

Interactive Blow Bar Selector Tool

Input your crusher model, feed material, abrasiveness, and tramp metal risk to receive an instant, data-driven recommendation for the optimal ATF blow bar metallurgy.

Download Our Comprehensive Selection Guide

Get a printable PDF featuring detailed material comparisons, application guidance, and troubleshooting tips for HSI blow bars.

Why Advanced Ceramic MMC Blow Bars Deliver Quantifiable 2–4× Life Extension & Reduced Cost Per Ton

Leveraging proprietary advanced metallurgical science, ATF’s Metal-Matrix Composite (MMC) blow bars precisely integrate ultra-hard ceramic inlays or robust Titanium Carbide (TiC) rods into a high-performance martensitic steel or high-chrome white iron matrix. This engineered composite architecture strategically positions the ceramic phase to provide unparalleled protection to the primary strike edge against aggressive micro-abrasion and premature edge rounding , critical for maintaining consistent product shape index (PSI) . Concurrently, the resilient metallic matrix efficiently dissipates high impact energy and mitigates spalling fatigue . In rigorously validated industrial applications characterized by severe abrasive loads and meticulously controlled mechanical shock, our professional engineering clients consistently report a quantifiable 2–4× extension in blow bar service life . This directly translates to significant reductions in operational downtime , optimization of maintenance intervals , and a demonstrably lower total cost per ton across aggregate, mining, and recycling operations, maximizing overall plant uptime and profitability .

How Advanced MMC Technology Works

- Targeted Edge Armor: Ultra-hard ceramic tiles or TiC rods are strategically positioned at the primary wear zone, maintaining an aggressive cutting profile and resisting premature edge rounding.

- Dynamic Load Sharing: The ductile metallic matrix (Martensitic or High Chrome) effectively carries and dissipates impact loads and mechanical shock, while the ceramic phase specifically handles high abrasive forces. This synergy prevents spalling fatigue.

- Stable Product Size Distribution (PSD): Slower, more uniform edge wear results in a significantly steadier product size between change-outs, minimizing fines drift and optimizing closed side settings (CSS).

- Maximized Uptime & Reduced Labor: Quantifiable longer wear life directly translates to fewer unscheduled stops for blow bar swaps, drastically reducing operational downtime, labor risk, and specific energy consumption.

Optimal Applications for MMC Blow Bars

- High abrasion, low shock environments: Ideal for washed stone, high-silica manufactured sand, basalt, and asphalt recycling where steel contaminants are completely removed.

- Clean, meticulously controlled feed: Best performance is achieved with pre-screened material, predictable top size, and minimal uncrushable objects, ensuring consistent material flow.

- Throughput & consistency sensitive operations: Essential for plants prioritizing stable tons/hour output, consistent product quality (PSI), and minimized maintenance interruptions.

Best-fit ATF alloys: Martensitic + Ceramic, High Chrome + Ceramic, High Chrome + Ceramic Plus. These are often manufactured with advanced foundry processes like lost foam casting for precision.

When Not to Implement MMC Blow Bars

- Frequent tramp metal / rebar presence: In applications with unavoidable steel contamination, always choose high-impact alloys like Manganese or Martensitic steel.

- Large, highly variable primary feed: For extreme primary impacts with unpredictable feed, prefer tough monolithic alloys like Manganese or Manganese + TiC composites to survive heavy blows and prevent erosion corrosion.

- Extreme hot/thermal shock scenarios: Consult with ATF engineering specialists for specific alloy and insert pattern recommendations in environments with rapid temperature fluctuations.

Critical Warning: If tramp-iron risk isn’t near zero, explicitly avoid high-chrome ceramic families due to their low impact toughness and high susceptibility to brittle fracture.

Common MMC Misapplication Symptoms & Solutions

- Ceramic tile spalling or cracking: Indicates impact loads exceeding the composite’s design envelope.

- Delamination at insert interface: Suggests insufficient backing support or severe, unmanaged impacts.

- Premature edge chipping: Often caused by unremoved steel, oversized feed material, or excessive rotor overspeeding.

Corrective actions: Implement enhanced steel removal protocols (e.g., higher gauss magnets), reduce rotor speed, slightly open S1/S2 curtain gaps, or transition to a tougher matrix alloy (Manganese, Martensitic, or Mn + TiC) to mitigate erosion corrosion.

Ceramic Insert MMC Design

Our Blow Bar Manufacturing Process: From Foundry to Finish

A detailed look into our advanced processes, including alloy preparation, precision casting, controlled heat treatment, finish machining, and rigorous quality control for superior HSI blow bars.

Maximizing Uptime: Optimizing Operations & Preventative Maintenance for HSI Blow Bars

Beyond metallurgy selection, consistent day-to-day setup, meticulous maintenance, and operational discipline collectively make the biggest difference in achieving superior service life, minimizing cost per ton, and ensuring unwavering product consistency. Implement these strategies for maximum throughput and profitability and robust preventative maintenance schedules for impact crushers .

⚡ Rotor Speed Management & Product Shape Index (PSI)

- Start conservatively; increase rotor speed only if excessive oversize material persists.

- Higher speed → increased reduction, more fines, and exponentially faster wear rate. Lower speed → reduced wear, more oversize, and potentially lower specific energy consumption.

- Match rotor speed to alloy capabilities: Ceramic/white-iron families thrive with controlled, consistent feed and moderate tip speeds.

- Monitor product shape index (PSI) to ensure desired cubical product without over-crushing.

| Rotor Speed | Wear Rate | Fines Production | Oversize Product |

|---|---|---|---|

| Lower | ↓ | ↓ | ↑ |

| Higher | ↑ | ↑ | ↓ |

🪛 Curtain Gaps (S1/S2) & Chamber Geometry

- Tighten S1 (primary apron) first if product is too coarse; open S2 (secondary apron) slightly to relieve excessive secondary loading and minimize erosion corrosion.

- Maintain precise symmetry in curtain settings to prevent one-sided wear patterns and potential rotor imbalance, critical for consistent product shape.

- Re-check and adjust curtain gaps after significant liner changes or rebuilds, as settled liners can alter effective settings.

- Optimize closed side setting (CSS) for desired product gradation and specific energy consumption.

📦 Feed Control & Even Distribution

- Ensure feed material is consistently centered and distributed across the rotor width to promote efficient rock-on-rock buffering and uniform blow bar wear.

- Utilize feeder systems (e.g., vibratory grizzly feeders – VGF) to achieve a steady, choke-fed chamber and avoid erratic surges that spike shock loads and accelerate wear.

- Proactively scalp oversize material; most HSIs perform optimally with feed material ≤ ~60–70% of the rotor diameter (check specific model guidelines).

- Implement material flow optimization strategies to maximize throughput and minimize unnecessary wear.

🧹 Fines & Moisture Management

- Pre-screen fines efficiently; excessive -10mm material acts like highly abrasive sandblasting media on blow bars and curtains, significantly increasing wear rate.

- Apply water judiciously and only as required for effective dust suppression; strictly avoid slurry conditions forming inside the crushing chamber to prevent erosion corrosion and material buildup.

- Regularly monitor carryback and material buildup on chamber walls and under the rotor—clean before it hardens to prevent imbalance and flow obstructions.

🧲 Tramp-Metal & Rebar Control

- Implement a multi-stage tramp metal removal system: robust overband magnets, efficient manual picking stations, and consider metal detection systems at the feed point.

- White-iron families (High Chrome ± Ceramic) possess inherently low toughness and require absolute minimal steel exposure to prevent brittle fracture and spalling.

- If tramp metal or rebar is unavoidable in your feed, always prioritize impact-tolerant alloys such as Manganese or Martensitic steel.

🔄 When to Flip & Rotate Blow Bars

- Reverse or flip bars at approximately 50% wear, or typically every 200-400 hours, depending on duty severity and specific wear patterns.

- Flip immediately if significant edge rounding exceeds 5mm (measure with a radius gauge) to maintain crushing efficiency and product shape.

- Proactively rotate blow bar positions around the rotor to equalize wear rates across all positions and extend the overall life of the set.

- Maintain a meticulous log of flip dates, positions, and operational hours to accurately track wear patterns and optimize future schedules. This is a key crusher rotor protection solution.

📅 Blow Bar Replacement Intervals & Monitoring

- Replace all blow bars before any single bar reaches the OEM wear-limit marking (typically 15-18mm remaining from the backside) to prevent rotor damage.

- Always change the entire set simultaneously when any single bar approaches its wear limit; never mix old and new bars in the same rotor as this causes imbalance and uneven wear.

- Strictly adhere to minimum thickness specifications—operating beyond this point risks catastrophic rotor damage, which is extremely costly to repair.

- Budget for replacements based on application-specific wear rates; refer to our comprehensive service life table and consult with our engineers for application-specific estimates.

- Regularly conduct impact crusher wear patterns analysis to inform maintenance decisions.

🧰 Inspection & Monitoring Intervals (HSI Crusher Preventative Maintenance Schedule)

- Daily: Conduct visual and auditory inspections for unusual vibration, noise, or product drift, indicating potential issues.

- Weekly: Measure blow bar edge rounding and thickness. Inspect wedge condition and seating integrity.

- Every 200–400 operating hours: Perform a full internal chamber inspection, including blow bars, rotor pockets, impact liners, and the rotor body for wear or damage.

- Implement a predictive maintenance schedule based on wear rates to prevent unplanned downtime and optimize cost-per-ton optimization for HSI crushers.

📈 The Cost-per-Ton Mindset & Optimization for HSI Crushers

- Key Formula: Cost/ton = (Total Blow Bar Set Cost + Downtime Cost + Labor Cost) ÷ Total Tons Produced until Change-out.

- Always include the significant cost of downtime (lost production and associated revenue) and labor in your total cost analysis, not just the part purchase price.

- Advanced alloys like Ceramic MMC often deliver a demonstrably lower cost-per-ton despite a higher initial purchase price, achieved through significantly longer operational life and fewer disruptive change-outs. This is critical for cost-per-ton optimization for HSI crushers.

Request a quick cost/ton model customized to your specific feed material, operating hours, and production targets for a precise financial projection.

🔧 Installation Best Practices for HSI Blow Bars

- Always replace blow bars in matched sets only, ensuring the same alloy type and weight (within ±3%) to maintain rotor balance and prevent uneven wear.

- Verify that all seating faces are meticulously flat and fully supported in the rotor pockets—no gaps or visible light under a straight edge.

- Torque all clamping wedges to the precise OEM specification (refer to your crusher manual) using a calibrated torque wrench.

- Critical Step: Re-torque all wedges after the initial 1-2 hours of warm-up operation; thermal expansion and settling of components can loosen fasteners.

- Post-installation, re-check rotor balance and verify no unusual vibration or noise at startup, which could indicate improper installation or imbalance.

- Maintain a detailed log of installation dates, operational hours, and individual blow bar reference numbers for comprehensive wear tracking and traceability.

| Crusher Size Class | Example Models | Recommended Wedge Torque Specification |

|---|---|---|

| Small HSI | Metso NP1110, Kleemann MR100, Sandvik QI341 | 350-450 Nm (260-330 ft-lb) |

| Medium HSI | Metso NP1315, Kleemann MR130, Sandvik QI442 | 450-550 Nm (330-405 ft-lb) |

| Large HSI | Metso NP1520, Powerscreen Trakpactor 550 | 600-750 Nm (440-550 ft-lb) |

Important: Always verify and adhere to the exact OEM torque specifications provided in your specific crusher model’s operational manual. Over-torquing risks damaging threads or components; under-torquing allows blow bar movement, leading to accelerated wear, uneven stress, and potential rotor damage.

Key Operational Best Practices (The “DO’s”)

- Always center the feed stream and maintain a full, consistent crushing chamber to promote rock-on-rock crushing.

- Accurately match your blow bar alloy to the specific impact vs. abrasion balance and the anticipated tramp metal risk in your feed.

- Meticulously log all operational settings (rotor speed, S1/S2 gaps) and rigorously correlate them with observed blow bar wear rates for continuous optimization.

- Adhere strictly to scheduled flip/rotation intervals; always replace blow bars in matched sets to ensure rotor balance and extend service life.

Common Operational Missteps (The “AVOID’s”)

- Avoid overspeeding the rotor solely to increase fines production—utilize dedicated screens for precise gradation control.

- Never operate high-chrome or ceramic-composite blow bars with known rebar contamination or in applications with unknown feed characteristics.

- Strictly prevent blow bars from wearing past their OEM wear-limit; this poses a severe risk of costly rotor damage and significant unplanned downtime.

- Eliminate asymmetric crusher settings (e.g., uneven curtain gaps) that lead to localized wear patterns, imbalance, and reduced blow bar life.

Quantified Blow Bar Service Life by Application & Material

These data points represent aggregated performance from rigorous field testing and client feedback. Use this information as a benchmark to estimate replacement intervals, project operational costs, and calculate the true cost per ton for your specific HSI crushing operation. Actual wear life is subject to feed characteristics, crusher settings, and maintenance practices, with a focus on cost-per-ton optimization for HSI crushers and preventative maintenance schedules for impact crushers .

| Application | Recommended Material | Service Life (Hours) | Typical Tonnage | Key Success Factors for Max Life |

|---|---|---|---|---|

| Clean Asphalt Recycling | High Chrome + Ceramic Plus | 1,500-2,400 | 150,000-300,000 tons | Pre-screen fines below 10mm; rigorous steel removal with powerful magnets; moderate rotor speed (650-750 RPM) and controlled feed. |

| Asphalt Recycling (Mixed RAP) | Martensitic + Ceramic | 1,000-1,800 | 100,000-220,000 tons | Robust overband magnet system for steel removal; consistent, centered feed distribution; regular blow bar rotation. |

| Concrete Recycling (Controlled Rebar) | Martensitic + Ceramic | 800-1,600 | 80,000-180,000 tons | Highly effective manual steel picking station; strict avoidance of oversized feed chunks; monitor ceramic integrity. |

| Concrete Recycling (Standard) | Martensitic Steel | 400-700 | 50,000-90,000 tons | Consistent manual rebar removal; mandatory bar flipping every 200-300 hours; moderate rotor speed and stable feed. |

| Limestone (Clean Secondary) | High Chrome + Ceramic | 1,500-3,000 | 200,000-400,000 tons | Grizzly pre-screen to remove fines and small contaminants; consistent feed rate; tight S1/S2 settings for optimal reduction. |

| Limestone (Secondary) | High Chrome | 800-1,500 | 100,000-200,000 tons | Ultra-clean feed material; strict avoidance of tramp metal; implement a regular blow bar rotation schedule. |

| Basalt / Hard Rock (Secondary) | High Chrome + Ceramic Plus | 1,200-2,200 | 150,000-280,000 tons | Requires exceptionally clean feed; effectively scalp oversize; utilize a lower rotor speed optimized for hard rock crushing. |

| Manufactured Sand Production | High Chrome + Ceramic | 1,500-2,800 | 180,000-350,000 tons | Demands ultra-clean washed feed; tight feed control and consistent gradation for optimal product shape index (PSI). |

| Mixed C&D Demolition | Martensitic Steel | 400-800 | 50,000-100,000 tons | Requires high variable feed tolerance; robust overband magnet system strongly recommended; slower rotor speed to mitigate impact. |

| Primary Crushing (Variable Feed) | Manganese (Mn18Cr2) | 600-1,200 | 80,000-160,000 tons | Relies on work-hardening in service; tolerates large feed and significant tramp metal; flip every 250-400 hours for even wear. |

| Primary Crushing (Aggressive) | Manganese + TiC | 800-1,400 | 100,000-180,000 tons | TiC inserts extend primary edge life in abrasive primary feeds; handles primary shocks; pre-screen recommended for fines. |

| Gravel / River Rock (Clean) | High Chrome + Ceramic | 1,800-3,200 | 220,000-420,000 tons | Low abrasion + low impact provides longest life; requires washed feed and consistent sizing for optimal performance. |

Cost per Ton Calculation: To determine your true cost per ton, divide your blow bar set cost (including procurement, shipping, and installation labor) by the total tonnage processed until change-out. Example: An $8,000 bar set ÷ 200,000 tons = $0.04/ton. Always incorporate downtime costs (lost production revenue) and labor costs into your comprehensive total cost analysis for an accurate picture. This is key for cost-per-ton optimization for HSI crushers.

Troubleshooting HSI Blow Bar Wear: Diagnostics & Preventative Maintenance

Experiencing premature failure, unexpected wear patterns, or inconsistent product gradation? Use this diagnostic guide to identify root causes and implement targeted corrective actions to significantly extend service life and reduce operational expenses through preventative maintenance schedules for impact crushers .

❌ Blow Bar Breaking or Catastrophic Cracking

Symptom: Catastrophic fracture through the blow bar body, often observed near mounting holes or mid-section, leading to sudden failure.

Common Causes (Wear Mechanisms):

- Severe tramp metal impact: Uncrushable rebar or steel in brittle high-chrome alloys (inherently low toughness).

- Excessive oversized feed: Material exceeding crusher design specifications, inducing extreme impact loads.

- Internal casting defects: Micro-voids, shrinkage cavities, or non-metallic inclusions compromising structural integrity.

- Operating past wear limit: Excessive thinning reduces structural integrity and impact resistance, accelerating spalling fatigue.

- Thermal shock: Rapid temperature changes, e.g., cold water spray on hot blow bars, creating internal stresses and micro-cracks.

Solutions:

- Switch to Martensitic (100-300 J/cm² impact strength) or Manganese (very high impact strength) for superior rebar tolerance.

- Install robust overband magnets, cross-belt magnets, and implement a dedicated manual steel picking station at the feed point.

- Add a grizzly or pre-screen to effectively remove oversized material (ensure feed ≤ 60-70% rotor diameter per OEM specs).

- Implement a strict replacement schedule: change bars at 70-75% wear (well before reaching OEM minimum thickness marking).

- Request ultrasonic testing certificates (UT) from your supplier to verify internal casting integrity and eliminate hidden defects.

- Optimize water spray for dust control only—never for rapid cooling of hot blow bars.

⚠️ Premature Edge Chipping or Spalling

Symptom: Small chips breaking off the leading edge of the blow bar very early in its service life (often before 200 hours of operation).

Common Causes (Wear Mechanisms):

- Excessive rotor speed: Tip speed too high for the feed material hardness and alloy’s impact characteristics.

- Unscreened fines content: Significant -10mm material acting as highly abrasive sandblasting media (micro-abrasion).

- Oversized feed particles: Impact loads exceeding the alloy’s design limits, particularly for brittle alloys.

- Incorrect alloy selection: Using a high-chrome alloy in a high-shock or mixed feed application.

- Poor feed distribution: Material consistently impacting only one side of the rotor, leading to uneven stress.

Solutions:

- Systematically reduce rotor speed by 10-15% (e.g., 750 RPM → 650 RPM); closely monitor product gradation and specific energy consumption.

- Install an effective pre-screen grizzly to remove fines below 10mm, minimizing abrasive wear.

- Verify and control feed size to ≤ 60-70% of rotor diameter, strictly adhering to OEM specifications.

- Consider a tougher, more impact-tolerant alloy: High Chrome (Lower Hardness) at 55-58 HRC or Martensitic steel at 48-54 HRC.

- Center the feed stream precisely using adjustable feed chute deflectors or belt adjustments.

- Slightly increase the S1 (primary apron) gap to reduce initial impact severity on the blow bar edge.

🔧 Uneven Blow Bar Wear (One-Sided or Localized)

Symptom: Blow bars on one side of the rotor wear 30-50% faster, or specific areas show disproportionate wear, causing rotor imbalance.

Common Causes:

- Off-center feeding: Feed conveyor or hopper consistently directing material to one side of the rotor.

- Asymmetric S1/S2 settings: Impact curtain gaps are not matched (e.g., S1=30mm left, S1=40mm right).

- Feeder belt tracking issues: Material shifts or piles unevenly during transport to the crusher.

- Rotor imbalance: Mixing different alloy types, weights, or excessively worn bars in the same rotor positions.

- Worn impact apron: Damaged or improperly adjusted apron liners deflecting material asymmetrically.

Solutions:

- Precisely center the feed stream using adjustable feed chutes, deflector plates, or by realigning the conveyor.

- Accurately measure S1 and S2 gaps with a caliper; adjust to match within a tight tolerance (e.g., ±2mm).

- Inspect and level the feeder pad foundation; check feeder belt tracking and alignment.

- Always replace blow bars in matched sets only (same alloy, weight within ±3%) to maintain rotor balance and optimal performance.

- Inspect and promptly replace worn feed chute or impact apron liners to ensure consistent material presentation.

- Implement a schedule to rotate blow bar positions every 200-300 hours to equalize wear across the rotor.

💥 Ceramic Insert Spalling or Delamination

Symptom: Ceramic tiles crack, delaminate, or break off from the steel or high-chrome matrix of MMC blow bars.

Common Causes (Wear Mechanisms):

- Thermal shock: Direct cold water spray hitting a hot ceramic surface, causing rapid contraction and stress.

- Impact overload: Shock loads exceeding the ceramic composite’s application envelope (e.g., from tramp metal or oversized feed).

- Poor casting bond: Insufficient adhesion or metallurgical bond between the ceramic insert and the matrix during manufacturing.

- Wrong duty application: Misapplication of secondary/tertiary ceramic bars in a primary crushing environment.

- Direct tramp metal strikes: Rebar or steel directly impacting the ceramic edge, leading to brittle fracture.

Solutions:

- Minimize water spray to only what’s required for dust control—never use for active blow bar cooling.

- Rigorously verify that your feed material consistently matches low-shock secondary/tertiary duty requirements (not primary crushing).

- Request comprehensive casting process documentation and bond quality testing reports from your blow bar supplier.

- Switch to Martensitic or Manganese alloys for significantly higher impact tolerance.

- Implement advanced tramp metal removal systems: install stronger magnets, conduct more thorough manual picking, and consider metal detection.

- Reduce rotor speed by 10-15% to lower the kinetic impact energy on the ceramic inserts.

📉 Faster Wear Rate Than Expected (Cost-per-Ton Increase)

Symptom: Blow bars wearing out in 50-70% of their projected service life hours, leading to higher operational cost per ton .

Common Causes:

- Excessive rotor speed: Wear rate increases exponentially with higher tip speeds.

- High fines content: Unscreened -10mm material acting as highly abrasive media, accelerating wear (micro-abrasion).

- Incorrect alloy selection: Alloy metallurgy not optimally matched to the feed material’s abrasiveness or impact characteristics.

- Moisture management issues: Excessively wet or sticky material increasing adhesion and wear from material buildup.

- Tight S1/S2 settings: Imposing excessive crushing chamber load and curtain impact frequency.

Solutions:

- Precisely calculate current rotor tip speed (π × rotor diameter × RPM); reduce if found excessive and monitor product gradation.

- Install an efficient scalping screen to effectively remove fines before the material enters the crusher feed.

- Strategically upgrade your alloy: High Chrome → High Chrome + Ceramic; Martensitic → Martensitic + Ceramic for enhanced wear.

- Minimize moisture content to the absolute minimum needed for dust control, strictly avoiding slurry conditions in the chamber.

- Open the S1 (primary apron) gap by 5-10mm to reduce secondary loading and lower the overall wear rate.

- Verify blow bars are genuine OEM-spec hardness (or from a reputable aftermarket supplier like ATF); request a hardness map certificate for traceability.

🔩 Wedge or Mounting System Issues (Loose Bars, Rotor Damage)

Symptom: Loose wedges, visible blow bar movement in rotor pockets, or failures of the mounting system components, leading to accelerated wear or rotor damage.

Common Causes:

- Insufficient torque: Wedges or clamping bolts not tightened to the manufacturer’s specified value.

- No re-torque after warm-up: Thermal expansion of rotor components loosens fasteners after initial operation.

- Worn wedge threads: Repeated use of wedges without replacement leading to compromised clamping force.

- Poor pocket fit: Blow bars rocking or not fully seated flush against the rotor pocket faces.

- Worn rotor pockets: Metal loss or deformation of rotor pockets from previous blow bar wear-through or impacts.

Solutions:

- Torque wedges precisely to OEM specification (refer to table above); ensure use of a calibrated torque wrench.

- Implement mandatory re-torquing after 1-2 hours of warm-up operation (thermal expansion settles components, requiring re-tightening).

- Replace wedges every 2-3 blow bar changes; meticulously inspect threads for any signs of wear, elongation, or damage.

- Verify blow bar seating faces are meticulously flat and fully supported—no light visible under a precision straight edge.

- Thoroughly inspect rotor pockets for wear, deformation, or damage; perform weld repair or replace the rotor if damage is severe.

- Ensure positive locating features (noses/tabs) on the blow bars correctly engage rotor pockets to prevent rotational movement.

Precision-Engineered Blow Bars Compatible with Leading HSI Crusher Brands

ATF designs, engineers, and stocks high-performance blow bars for the most popular horizontal shaft impactors worldwide. Select your crusher brand below to view supported models and compatible alloy options, including specialized aftermarket blow bars for Metso NP1315 and Sandvik QI442 wear parts equivalent .

Metso (Nordberg) – NP Series

- NP1110

- NP1213 (Aftermarket blow bars for NP1213)

- NP1315 (Aftermarket blow bars for NP1315)

- NP1415

- NP1520

- NP13

- NP15

Kleemann – MOBIREX (MR)

- MR 100(i) NEO

- MR 110 EVO2

- MR 130 EVO2 (Aftermarket blow bars for Kleemann MR130)

- MR 130 PRO

- MR 122 Z

- MR 170 Z

Sandvik – QI Series

- QI341

- QI353

- QI442 (Sandvik QI442 wear parts equivalent)

Terex Pegson / Powerscreen – Trakpactor

- Trakpactor 230 / 230SR

- Trakpactor 260 / 260SR

- Trakpactor 290 / 290SR

- Trakpactor 320 / 320SR

- Trakpactor 480 (legacy)

- Trakpactor 550 / 550SR

- 4242SR (legacy)

- 428 (legacy)

Terex Finlay – I / IC Series

- I-100

- IC-100

- IC-110 / IC-110RS

- I-120

- I-130

- I-140

McCloskey – I Series

- I34 / I34R (compact)

- I44v3 (Aftermarket I44 blow bars)

- I54v3 (Aftermarket I54 blow bars)

- I4C

- I3C

Keestrack – R / I Series

- R3

- R4

- R5

- R6

- I4e

Rockster – R Series

- R700S

- R900

- R1000S

- R1100S

- R1100DS

RUBBLE MASTER – RM Series

- RM 60GO!

- RM 80GO!

- RM 70GO!

- RM 90GO!

- RM 100GO!

- RM 120X

Lippmann – Impactors

- 4800R

- I-1312 (tracked)

IROCK – TC / RDS Series

- TC-15

- TC-20

Eagle Crusher – UltraMax®

- 1200-25 CV / 1200-25 CC / 1200-25 OCSS

- 1400-45 OC

- 1600-69 CCS / 1600-69X-OC

HAZEMAG – HPI / HPI-H / APK / APPH

We support a full range of HAZEMAG primary (HPI & HPI-H) and secondary (APK/APPH) impactors. Provide your exact sub-model (e.g., HPI-H 1315) in your RFQ for precise fitment and optimal alloy recommendations.

Striker – HQR Series

- HQR1112

- HQR1312

Terex Cedarapids – IP / TI Series

- IP1313

- IP1316

- IP1516

- TI4143

- CRH1316 (portable plant with IP1316)

Terex EvoQuip – Cobra

- Cobra 230

- Cobra 230R

KPI-JCI / ASTEC – Andreas HSI

Supported platforms include FT4250 plants and various Andreas HSI units. For precise compatibility, please specify your exact crusher model and rotor size in your Request for Quote (RFQ).

SBM Mineral Processing – REMAX

- REMAX 200

- REMAX 300

- REMAX 400

- REMAX 450

- REMAX 600

Portafill – MI Series

Inertia – Phoenix / Falcon

- 4048 Phoenix

- 5066 Falcon

Hartl (legacy) – PC Series

- PC 1

- PC 3

- PC 5

Many Hartl impactor models are legacy; for precise cross-reference, please provide your exact part number or a detailed drawing in your RFQ.

Don’t see your exact HSI sub-model or need a custom solution? ATF proudly supports over 100 OEM specifications, including various legacy variants, and offers aftermarket blow bars for a wide range of popular models such as Metso NP1213 , Sandvik QI442 , Kleemann MR130 , and McCloskey I44 and I54 blow bars. Request a custom quote with your make/model and original part reference to confirm if we can supply high-performance blow bars, including advanced ceramic insert options, engineered specifically for your needs.

OEM Compatibility: Popular HSI Crusher Models & Optimized Blow Bar Alloys

Explore recommended alloy options and typical duty profiles for a selection of popular HSI impact crusher models. Engage with our engineers to discuss specific metallurgy choices, optimal change-out intervals, and profile geometry tailored for your unique operating conditions. This includes our range of aftermarket blow bars for Metso NP1315 , Sandvik QI442 wear parts equivalent , and Tesab blow bars .

| Brand | Model | Typical Duty Profile | Recommended Alloys* |

|---|---|---|---|

| Metso | NP1110 | Secondary limestone/asphalt recycling, clean feed | High-Chrome; High-Chrome + Ceramic |

| Metso | NP1213 | Secondary crushing; controlled feed size and minimal tramp (Aftermarket NP1213 blow bars available) | High-Chrome; High-Chrome + Ceramic |

| Metso | NP1315 | Secondary crushing; variable rock, mixed aggregates with some impact (Aftermarket NP1315 blow bars available) | Martensitic; Martensitic + Ceramic |

| Metso | NP1415 | High-throughput quarry applications, consistent feed | High-Chrome + Ceramic; Ceramic Plus |

| Metso | NP1520 | Large scale secondary crushing, high reduction ratio (Aftermarket NP1620 blow bars available) | High-Chrome + Ceramic; Ceramic Plus |

| Metso | NP13 | Mobile/compact plants, often for recycling or smaller quarries | High-Chrome; Martensitic |

| Metso | NP15 | High reduction applications, typically clean feed | High-Chrome + Ceramic |

| Kleemann | MR 100(i) NEO | Urban concrete and mixed recycling, often with rebar | Martensitic; Martensitic + Ceramic |

| Kleemann | MR 110 EVO2 | General recycling & quarry applications, versatile | Martensitic; Martensitic + Ceramic |

| Kleemann | MR 130 EVO2 | High-capacity recycling of concrete and asphalt, robust (Aftermarket Kleemann MR130 blow bars available) | Martensitic; Martensitic + Ceramic |

| Sandvik | QI341 | Mobile recycling and contract crushing, variable feed | Martensitic; Martensitic + Ceramic |

| Sandvik | QI353 | Quarry & recycling, balanced performance needs | Martensitic + Ceramic; High-Chrome |

| Sandvik | QI442 | High-throughput mobile applications, often for aggregates (Sandvik QI442 wear parts equivalent) | Martensitic + Ceramic; High-Chrome + Ceramic |

| Powerscreen | Trakpactor 230/230SR | Compact recycling and demolition, moderate impact | Martensitic; Martensitic + Ceramic |

| Powerscreen | Trakpactor 260/260SR | Recycling & aggregates production, versatile feed | Martensitic; High-Chrome |

| Powerscreen | Trakpactor 290/290SR | Versatile secondary crushing, mixed materials | Martensitic; High-Chrome |

| Powerscreen | Trakpactor 320/320SR | High-capacity secondary crushing, aggregates production | High-Chrome; High-Chrome + Ceramic |

| Powerscreen | Trakpactor 550/550SR | Large quarry applications, high tonnage output | High-Chrome + Ceramic |

| Terex Finlay | I-140 | Quarry & mining, often primary or large secondary | High-Chrome + Ceramic; Martensitic |

*Optimal alloy selection is highly dependent on specific feed material characteristics, percentage of fines, top feed size, and critical tramp-iron risk. Always consult with an ATF application engineer for precise tuning and guaranteed performance.

Ensure Perfect Fit: Confirm Blow Bar Compatibility for Your HSI Crusher

Search our comprehensive database by brand, impact crusher series, and specific model to view compatible blow bars and related wear parts. Our detailed cross-reference ensures precise fitment and optimal performance for various impact crusher blow bars , including aftermarket blow bars for Metso , Sandvik , and Kleemann .

Don’t see your exact model or require a custom solution? ATF offers specialized reverse-engineering services from your sample part or detailed drawings to ensure a perfect fit for aftermarket HSI blow bars for any major brand, including Tesab blow bars or McCloskey I44 blow bars .

Blow Bar Compatibility Reference

| Brand | Model | Reference | Material | Weight |

|---|---|---|---|---|

| Eagle | 1000 (UM-15) | 1000 (UM-15) | Martensitic; High Chrome; Ceramic Inserts | 240.000 |

| Eagle | 1200 (UM-25) | 1200 (UM-25) | Martensitic; High Chrome; Ceramic Inserts | 280.000 |

| Eagle | 1400 (UM-45) | 1400 (UM-45) | Martensitic; High Chrome; Ceramic Inserts | 315.000 |

| Eagle | 1600 (UM-69) | 1600 (UM-69) one piece | Martensitic; High Chrome; Ceramic Inserts | 590.000 |

| Eagle | 500 (UM-05) | 500 (UM-05) | Martensitic; High Chrome; Ceramic Inserts | 155.000 |

| Hartl | 1060 | 1060 | Martensitic; High Chrome; Ceramic Inserts | 192.000 |

| Hartl | 1270 | 1270 | Martensitic; High Chrome; Ceramic Inserts | 245.000 |

| Hartl | 1310 | 1310 | Martensitic; High Chrome; Ceramic Inserts | 355.000 |

| Hazemag | AP-PM 1822 | AP-PM 1822 | Martensitic; High Chrome; Ceramic Inserts | 865.000 |

| Hazemag | AP-PM 2225 | AP-PM 2225 | Martensitic; High Chrome; Ceramic Inserts | 1300.000 |

| Hazemag | AP-S 0813 | AP-S 0813 | Martensitic; High Chrome; Ceramic Inserts | 53.000 |

| Hazemag | APK1013 | APK1013 | Martensitic; High Chrome; Ceramic Inserts | 295.000 |

| Hazemag | APK105 | APK105 | Martensitic; High Chrome; Ceramic Inserts | 112.000 |

| Hazemag | APK40 | HAZ789 | Martensitic; High Chrome; Ceramic Inserts | 83.000 |

| Hazemag | APK50 | HAZ791 | Martensitic; High Chrome; Ceramic Inserts | 150.000 |

| Hazemag | APK60 | HAZ 850A | Martensitic; High Chrome; Ceramic Inserts | 182.000 |

| Hazemag | APP1013 | APP1013 | Martensitic; High Chrome; Ceramic Inserts | 256.000 |

| Hazemag | HAZ1013 | HAZ1013 | Martensitic; High Chrome; Ceramic Inserts | 300.000 |

| Hazemag | HAZ1036 | HAZ1036 | Martensitic; High Chrome; Ceramic Inserts | 270.000 |

| Hazemag | HAZ790 | HAZ790 | Martensitic; High Chrome; Ceramic Inserts | 115.000 |

| Hazemag | HAZ793 (2 grooves)- M3717454 | HAZ793 -M3717454 | Martensitic; High Chrome; Ceramic Inserts | 115.000 |

| Hazemag | HPI2025 | HPI2025 | Martensitic; High Chrome; Ceramic Inserts | 946.000 |

| Hazemag | M0172990 | M0172990 | Martensitic; High Chrome; Ceramic Inserts | 237.000 |

| Hazemag | M0174348 | M0174348 | Martensitic; High Chrome; Ceramic Inserts | 275.000 |

| Hazemag | M1022/APS1313/AP-PH1214 | M1022/APS1313/AP-PH1214 | Martensitic; High Chrome; Ceramic Inserts | 420.000 |

| Hazemag | M596 | M596 | Martensitic; High Chrome; Ceramic Inserts | 9.700 |

| Hazemag | MOD 686 | MOD 686 | Martensitic; High Chrome; Ceramic Inserts | 57.000 |

| Inertia | 4048 | 4048 | Martensitic; High Chrome; Ceramic Inserts | 308.000 |

| Inertia | 5066 | 5066 | Martensitic; High Chrome; Ceramic Inserts | 425.000 |

| Irock | S3151-13-4 | S3151-13-4 | Martensitic; High Chrome; Ceramic Inserts | 385.000 |

| Irock | S3151-13-5 | S3151-13-5 | Martensitic; High Chrome; Ceramic Inserts | 308.000 |

| Keestrack | Destroyer 1112,1113 | Destroyer 1112,1113 | Martensitic; High Chrome; Ceramic Inserts | 250.000 |

| Keestrack | R3 | R3 | Martensitic; High Chrome; Ceramic Inserts | 215.000 |

| Keestrack | R3 NEW | R3 NEW | Martensitic; High Chrome; Ceramic Inserts | 230.000 |

| Keestrack | R5 | R5 | Martensitic; High Chrome; Ceramic Inserts | 275.000 |

| Keestrack | R5 NEW | R5 NEW | Martensitic; High Chrome; Ceramic Inserts | 270.000 |

| Keestrack | R6 KP | R6 KP | Martensitic; High Chrome; Ceramic Inserts | 320.000 |

| Keestrack | R6 KT (Destroyer) | R6 KT (Destroyer) | Martensitic; High Chrome; Ceramic Inserts | 306.000 |

| Kleeman | MR-130 Z/R | 10665-2 | Martensitic; Martensitic+Ceramic; High Chrome; Other materials on request | 564.000 |

| Kleemann | MR100Z/ SHB10 (X shape) | MR100Z/ SHB10 (X shape) | Martensitic; High Chrome; Ceramic Inserts | 250.000 |

| Kleemann | MR110Z EVO (C shape) | MR110Z EVO (C shape) | Martensitic; High Chrome; Ceramic Inserts | 275.000 |

| Kleemann | MR122Z /SHB12 (X shape) | MR122Z /SHB12 (X shape) | Martensitic; High Chrome; Ceramic Inserts | 318.000 |

| Kleemann | MR130Z EVO (C shape) | MR130Z EVO (C shape) | Martensitic; High Chrome; Ceramic Inserts | 360.000 |

| Kleemann | MR130Z/SHB13 (S shape) | MR130Z/SHB13 (S shape) | Martensitic; High Chrome; Ceramic Inserts | 367.000 |

| Kleemann | MR150Z (C shape) | MR150Z (C shape) | Martensitic; High Chrome; Ceramic Inserts | |

| Kleemann | MR150Z (X shape) | MR150Z (X shape) | Martensitic; High Chrome; Ceramic Inserts | 440.000 |

| Kleemann | SHB14 | SHB14 | Martensitic; High Chrome; Ceramic Inserts | 370.000 |

| KPI-JCI(ASTEC) | FT4240 | FT4240 | Martensitic; High Chrome; Ceramic Inserts | 177.000 |

| KPI-JCI(ASTEC) | FT4250 | FT4250 | Martensitic; High Chrome; Ceramic Inserts | 230.000 |

| KPI-JCI(ASTEC) | FT5260 | FT5260 | Martensitic; High Chrome; Ceramic Inserts | 399.000 |

| Lippmann | 4248 | 4248 | Martensitic; High Chrome; Ceramic Inserts | 270.000 |

| Lippmann | 5165 | 5165 | Martensitic; High Chrome; Ceramic Inserts | 375.000 |

| McCloskey | I34 | I34 | Martensitic; High Chrome; Ceramic Inserts | 155.000 |

| McCloskey | I44 | I44 | Martensitic; High Chrome; Ceramic Inserts | 215.000 |

| McCloskey | I4C | I4C | Martensitic; High Chrome; Ceramic Inserts | 305.000 |

| McCloskey | I54 | I54 | Martensitic; High Chrome; Ceramic Inserts | 370.000 |

| Metso | NP-LT 1007 | NP-LT 1007 | Martensitic; High Chrome; Ceramic Inserts | 140.000 |

| Metso | NP-LT 1110 | NP-LT 1110 | Martensitic; High Chrome; Ceramic Inserts | 220.000 |

| Metso | NP-LT 1213/1313 (NP13) | N62252515 | Manganese; Martensitic; High Chrome; Ceramic Inserts | 335.000 |

| Metso | NP-LT 1213/1313 (NP13) | NP-LT 1213/1313 (NP13) | Martensitic; High Chrome; Ceramic Inserts | 325.000 |

| Metso | NP-LT 1315/1415 (NP15) | NP-LT 1315/1415 (NP15) | Martensitic; High Chrome; Ceramic Inserts | 445.000 |

| Metso | NP1520/1620 | NP1520/1620 | Martensitic; High Chrome; Ceramic Inserts | 730.000 |

| Portafill | 7000-IC Full | 7000-IC Full | Martensitic; High Chrome; Ceramic Inserts | 144.000 |

| Rockster | R700 | R700 | Martensitic; High Chrome; Ceramic Inserts | 128.000 |

| Rockster | R900 | R900 | Martensitic; High Chrome; Ceramic Inserts | 175.000 |

| Rubblemaster | RM100 | RM100 | Martensitic; High Chrome; Ceramic Inserts | 175.000 |

| Rubblemaster | RM120 | RM120 | Martensitic; High Chrome; Ceramic Inserts | 275.000 |

| Rubblemaster | RM60 | RM60 | Martensitic; High Chrome; Ceramic Inserts | 71.000 |

| Rubblemaster | RM70 | RM70 | Martensitic; High Chrome; Ceramic Inserts | 93.000 |

| Rubblemaster | RM80/90 | RM80/90 | Martensitic; High Chrome; Ceramic Inserts | 136.000 |

| Sandvik | CI124 | CI124 | Martensitic; High Chrome; Ceramic Inserts | 218.000 |

| Sandvik | CI224 | CI224 | Martensitic; High Chrome; Ceramic Inserts | 436.000 |

| Sandvik | QI340 (Extec I-C13, APP1013) | QI340 (Extec I-C13, APP1013) | Martensitic; High Chrome; Ceramic Inserts | 256.000 |

| Sandvik | QI341 (QI240) | QI341 (QI240) | Martensitic; High Chrome; Ceramic Inserts | 230.000 |

| Sandvik | QI353 | QI353 | Martensitic; High Chrome; Ceramic Inserts | 312.000 |

| Sandvik | QI441 (QI440) | QI441 (QI440) | Martensitic; High Chrome; Ceramic Inserts | 345.000 |

| SBM | 10.6.4 | 10.6.4 | Martensitic; High Chrome; Ceramic Inserts | 119.000 |

| SBM | 1311/1313 | 1311/1313 | Martensitic; High Chrome; Ceramic Inserts | 345.000 |

| SBM | REMAX 200 | REMAX 200 | Martensitic; High Chrome; Ceramic Inserts | 194.000 |

| SBM | REMAX 300 | REMAX 300 | Martensitic; High Chrome; Ceramic Inserts | 229.000 |

| SBM | REMAX 400 | REMAX 400 | Martensitic; High Chrome; Ceramic Inserts | 275.000 |

| Striker | 1112/1312 | 1112/1312 -100mm | Martensitic; High Chrome; Ceramic Inserts | 338.000 |

| Striker | 1112/1312 | 1112/1312 -120mm | Martensitic; High Chrome; Ceramic Inserts | 400.000 |

| Striker | 1315 | 1315 | Martensitic; High Chrome; Ceramic Inserts | 460.000 |

| Striker | 907 | 907 | Martensitic; High Chrome; Ceramic Inserts | 160.000 |

| Terex Cedarapids | 5048 HIS | 5048 HIS | Martensitic; High Chrome; Ceramic Inserts | 365.000 |

| Terex Cedarapids | 5064 HIS | 5064 HIS | Martensitic; High Chrome; Ceramic Inserts | 240.000 |

| Terex Evoquip | Cobra 230/260 | Cobra 230/260 | Martensitic; High Chrome; Ceramic Inserts | 140.000 |

| Terex Evoquip | Cobra 230/260 (Short/Half) | Cobra 230/260 (Short/Half) | Martensitic; High Chrome; Ceramic Inserts | 116.000 |

| Terex Evoquip | Cobra 290 | Cobra 290 | Martensitic; High Chrome; Ceramic Inserts | 190.000 |

| Terex Finlay | I-100 (IC-100) | I-100 (IC-100) | Martensitic; High Chrome; Ceramic Inserts | 140.000 |

| Terex Finlay | I-110 (I-1310) | I-110 (I-1310) | Martensitic; High Chrome; Ceramic Inserts | 187.000 |

| Terex Finlay | I-120 | I-120 | Martensitic; High Chrome; Ceramic Inserts | 214.000 |

| Terex Finlay | I-130 | I-130 | Martensitic; High Chrome; Ceramic Inserts | 365.000 |

| Terex Finlay | I-140 | I-140 | Martensitic; High Chrome; Ceramic Inserts | 377.000 |

| Terex Finlay | IC110 | IC110 | Martensitic; High Chrome; Ceramic Inserts | 190.000 |

| Terex Powerscreen | Pegson 1412 tracpactor (Hazemag chamber) | Pegson 1412 tracpactor (Hazemag chamber) | Martensitic; High Chrome; Ceramic Inserts | 425.000 |

| Terex Powerscreen | Pegson 428 | Pegson 428 | Martensitic; High Chrome; Ceramic Inserts | 206.000 |

| Terex Powerscreen | Trakpactor 320 (New clamped) | Trakpactor 320 (New clamped) | Martensitic; High Chrome; Ceramic Inserts | 214.000 |

| Terex Powerscreen | Trakpactor 320 (Old clamped) | Trakpactor 320 (Old clamped) | Martensitic; High Chrome; Ceramic Inserts | 215.000 |

| Terex Powerscreen | Trakpactor 550 (Hazemag chamber) | Trakpactor 550 (Hazemag chamber) | Martensitic; High Chrome; Ceramic Inserts | 425.000 |

| Terex Powerscreen | Trakpactor 550 (Terex chamber) | Trakpactor 550 (Terex chamber) | Martensitic; High Chrome; Ceramic Inserts | 390.000 |

| Terex Powerscreen | XH250 | XH250 | Martensitic; High Chrome; Ceramic Inserts | 140.000 |

| Terex Powerscreen | XH320 (unclamped) | XH320 (unclamped) | Martensitic; High Chrome; Ceramic Inserts | 215.000 |

| Tesab | RK1012 | RK1012 | Martensitic; High Chrome; Ceramic Inserts | 192.000 |

| Tesab | RK623/624 | 2-320 | Martensitic; High Chrome; Ceramic Inserts | 104.000 |

This static list is a subset for quick reference. Use the filters above for the full, up-to-date catalog.

Industries We Empower with Superior HSI Blow Bars

Mining & Quarrying

Precision-engineered wear parts for high-tonnage operations in hard rock mining, including iron ore, copper, gold, and aggregate extraction.

- Optimized for primary & secondary crushing circuits

- Designed for high-impact abrasive applications

- Guaranteed extended service life in demanding conditions

- Solutions for managing specific energy consumption

Aggregates Production

Optimized HSI crusher parts ensuring consistent product gradation and superior cubical shape (PSI) for sand, gravel, and crushed stone operations.

- Manufactured sand (M-sand) production specialists

- Critical for road base & high-spec construction aggregates

- Maintains stable Closed Side Setting (CSS) for compliance

- Reduces micro-abrasion for longer component life

Recycling & C&D

Rebar-tolerant and highly durable wear parts for efficient concrete recycling, asphalt reclamation, and demanding demolition waste processing.

- Specialized solutions for concrete & demolition waste

- Optimized for asphalt & RAP processing with minimal loss

- Contamination-resistant designs (manganese, martensitic)

- Reduces operational downtime from tramp metal incidents

Cement Production

Reliable, high-availability wear parts for continuous-duty limestone crushing in cement plants, lime operations, and clinker production.

- Optimized for limestone & cement raw materials crushing

- Ensures efficient raw mix preparation crushing

- Meets stringent high-availability and reliability requirements

- Resistant to erosion corrosion in specific applications

What are HSI blow bars and how do they work?

HSI blow bars are the primary wear elements in horizontal shaft impact (HSI) crushers.

These robust, rectangular wear parts are precisely mounted on the rotor, where they

strike incoming feed material at high speeds (often > 50 m/s). This high-energy impact

shatters the material against fixed impact curtains (breaker plates) within the crushing

chamber. The material is then further reduced as it cascades through the chamber,

achieving desired product gradation. Blow bar material, profile, and operational

setup directly influence reduction ratio, product shape index (PSI), wear life, and overall cost per ton.

What advanced materials are HSI blow bars made from?

Modern HSI blow bars are precision-cast from a range of advanced alloys engineered

for specific wear mechanisms:

- High Chrome White Iron: (e.g., ASTM A532 Class III Type A equivalent) Offers exceptional abrasion resistance but is sensitive to impact.

- Martensitic Steel: (e.g., DIN 1.2704 / ASTM A536 equivalent) Provides a superior balance of impact toughness and good abrasion resistance.

- Austenitic Manganese Steel: (e.g., ASTM A128 Grade C equivalent) Excels in high-impact, work-hardening applications with tramp metal.

- Metal Matrix Composites (MMC): Advanced designs embed ultra-hard ceramic inserts or Titanium Carbide (TiC) rods into high chrome or martensitic matrices to dramatically improve wear resistance and extend life in highly abrasive, controlled-impact applications.

The optimal material choice is critical for maximizing performance and minimizing cost per ton.

Which blow bar material is best for my specific application?

The optimal blow bar material is determined by a comprehensive assessment of feed

hardness, abrasiveness, maximum feed size, and the unavoidable presence of tramp metal (rebar)

in the material stream:

- High Chrome: Ideal for ultra-clean, highly abrasive, non-metallic feeds where impact is consistently low.

- High Chrome + Ceramic Inserts: Delivers extended operational life in extremely abrasive but stable feed, minimizing micro-abrasion.

- Martensitic Steel (with or without ceramic): The preferred choice for applications with better impact resistance, such as concrete recycling where some rebar ingress is expected.

- Manganese Steel: Specifically engineered for primary crushing duties involving heavy impact and a high, unavoidable risk of tramp metal.

In industrial practice, selecting the material that precisely matches your actual

operating conditions (rather than solely by initial price) is paramount for reducing total cost per ton.

What is the difference between high chrome and martensitic blow bars?

High chrome blow bars (e.g., ASTM A532 Class III Type A equivalent) offer very high abrasion

resistance due to their hard chromium carbide microstructure, but are more brittle

and highly sensitive to large uncrushable objects or tramp metal impacts. They

excel in clean, consistent feeds.

Conversely, martensitic steel blow bars (e.g., DIN 1.2704 / ASTM A536 equivalent) are

thermo-mechanically treated to be less hard but significantly tougher (100-300 J/cm² impact strength),

allowing them to tolerate more impact and occasional metal in the feed without fracturing.

The choice represents a critical engineering trade-off between maximizing wear life in

abrasive conditions versus ensuring robust impact resistance in variable or contaminated feeds.

What are ceramic insert (MMC) blow bars and when do they pay off?

Ceramic insert, or Metal Matrix Composite (MMC), blow bars combine a high-performance

metallic base (high chrome or martensitic steel) with strategically placed,

ultra-hard ceramic tiles or Titanium Carbide (TiC) rods embedded in the primary wear zones.

This composite architecture leverages the extreme hardness of ceramic to dramatically slow

down wear in the working area, often providing a quantifiable 2–4 times longer

service life compared to standard monolithic bars in suitable applications.

They pay off significantly in highly abrasive, low-impact environments with meticulously

controlled feed (e.g., manufactured sand, clean asphalt recycling) by reducing downtime,

optimizing maintenance intervals, and lowering the overall cost per ton.

How long do HSI blow bars typically last in operational service?

There is no universal service lifetime for HSI blow bars, as it is highly dependent

on a multitude of operational variables: specific feed material characteristics (hardness,

abrasiveness, moisture), precise crusher settings (rotor speed, S1/S2 curtain gaps),

the chosen alloy metallurgy, and actual production hours.

- In aggressive concrete recycling, martensitic bars may last 400-700 hours.

- In clean asphalt or limestone with High Chrome or ceramic inserts, operational life can extend to 1,500–3,000 hours.

Proactive tracking of wear rates (e.g., mm per hour, or tonnes per blow bar set) is the most

reliable method to compare performance between different materials and optimize your replacement schedule.

What is the optimal rotor speed for HSI blow bars in concrete recycling?

The optimal rotor speed for HSI blow bars in concrete recycling involves a trade-off

between reduction ratio, desired product shape index (PSI), and blow bar wear rate.

Higher rotor speeds generally increase fines production and reduction but significantly

accelerate wear. Conversely, lower speeds reduce wear but may lead to increased oversize.

For concrete recycling, a starting point of 650-750 RPM is often recommended, but it

should be fine-tuned based on your specific crusher model, feed material abrasiveness,

and the desired product gradation. Monitoring blow bar wear, vibration, and specific

energy consumption (kWh/ton) helps identify the most efficient speed for your operation.

How does tramp metal impact the integrity of high chrome blow bars?

Tramp metal (e.g., rebar, uncrushable steel) severely compromises the integrity of

high chrome blow bars due to their inherent brittleness and low impact strength (~10 J/cm²).

Unlike tougher alloys that deform under impact, high chrome material is prone to catastrophic

brittle fracture, cracking, or large-scale spalling when struck by foreign metallic objects.

This can lead to premature blow bar failure, costly unplanned downtime, and potentially

severe damage to the rotor and other crusher components. For applications with unavoidable

tramp metal, tougher alloys like Martensitic or Manganese steel are strongly recommended,

along with robust pre-screening and magnetic separation systems.

What is the significance of “work-hardening” in manganese blow bars?

“Work-hardening” is a critical property of austenitic manganese steel (e.g., ASTM A128

Grade C equivalent) that makes it exceptionally valuable for high-impact crushing. When

manganese blow bars are subjected to repeated impact (e.g., striking hard rock), their

surface hardness increases significantly (from an initial HB 200-240 up to HB 550+).

This localized increase in surface hardness enhances wear resistance precisely where it’s

needed most, while the underlying core remains tough and ductile to absorb extreme shock

loads. This characteristic makes manganese blow bars ideal for primary crushing applications

with large, variable feed and high tramp metal risk.

How do ceramic inserts extend blow bar service life in abrasive applications?

Ceramic inserts (Metal Matrix Composites – MMCs) extend blow bar service life by leveraging

the extreme hardness (typically HV 1600) of ceramic materials. These inserts are

strategically embedded into the blow bar’s metallic matrix at the primary strike edge,

which is the zone experiencing the most aggressive micro-abrasion.

The ceramic acts as a highly wear-resistant shield, protecting the softer metallic matrix

from abrasive wear, micro-chipping, and edge rounding. This composite design allows the

metallic backbone to absorb impact loads while the ceramic maintains a sharp, aggressive

crushing profile for extended periods, resulting in 2-4x longer wear life in controlled,

highly abrasive environments.

What are the key parameters to measure for blow bar wear analysis?

To conduct a comprehensive blow bar wear analysis and optimize performance, key parameters to measure include:

- Edge Rounding: Quantify the radius of the leading edge, typically with a radius gauge (e.g., 5mm or 10mm). Excessive rounding reduces crushing efficiency and product shape.

- Thickness Reduction: Measure the remaining thickness of the blow bar, especially near the wear limit markers, to track overall material loss.

- Weight Loss: Weigh bars at regular intervals to determine material consumption rate per hour or per ton processed.

- Wear Pattern Uniformity: Visually inspect for uneven wear across the bar surface and between different rotor positions.

- Operational Data: Correlate wear measurements with total operating hours, tonnage processed, feed material characteristics, and crusher settings (rotor speed, S1/S2 gaps) for accurate performance tracking and cost-per-ton calculations.

How can I proactively extend the operational life of my HSI blow bars?

Maximizing blow bar operational life involves a combination of best practices:

- Maintain a consistent, centered feed size and rigorously avoid oversized boulders or surges.

- Implement advanced tramp metal removal systems (powerful magnets, manual picking, metal detectors) to prevent premature failure.

- Operate within the manufacturer’s recommended rotor speed and optimize crusher settings (S1/S2 curtain gaps) for your specific material.

- Ensure correct blow bar seating, proper tightening with calibrated torque, and regular rotor balancing to prevent uneven wear and vibration.

- Adhere to a proactive schedule to rotate or turn blow bars before they reach their safe wear limit, utilizing all working edges efficiently.

- Pre-screen fines to reduce “sandblasting” wear, and manage moisture to avoid slurry conditions.

When should HSI blow bars be turned, rotated, or flipped?

Blow bars should be proactively turned, rotated, or flipped when the primary working

edge approaches the manufacturer’s minimum recommended thickness, or when wear becomes

significantly uneven and begins to negatively affect product size, shape (PSI), or

causes abnormal vibration in the crusher.

Typically, this occurs at approximately 50% wear or every 200-400 operating hours,

depending on the severity of the application. Timely rotation or flipping allows you

to safely utilize all available working edges, maximize the total tonnage processed

per blow bar set, and prevents costly damage to the rotor by maintaining proper balance.

Always refer to your crusher OEM manual for specific rotation diagrams and instructions.

What are the critical signs that HSI blow bars need immediate replacement?

Immediate replacement of HSI blow bars is crucial to maintain crushing efficiency,

prevent costly damage to the rotor, and ensure operational safety. Key indicators include:

- Visible Cracking or Breakage: Any signs of catastrophic fracture, significant cracking, or missing large pieces.

- Excessive Wear: When blow bars are worn close to the rotor body, bolt holes, or past the OEM minimum thickness marking.

- Inconsistent Product: Difficulty maintaining the required product size, shape, or desired gradation (e.g., increased oversize or fines drift).

- Increased Vibration or Abnormal Noise: Unexplained spikes in crusher vibration, unusual grinding sounds, or abnormal operational noise from the crushing chamber.

- Rotor Imbalance: Indications of rotor imbalance due to uneven wear or loss of blow bar material.

Blow bars must always be replaced well before they reach the critical minimum thickness

specification to safeguard the expensive rotor assembly and prevent unscheduled downtime.

Can I use aftermarket HSI blow bars instead of OEM parts?

Yes, many industrial operations successfully utilize high-quality aftermarket HSI blow bars as a cost-effective alternative to OEM parts. The critical factors for success are

ensuring that the aftermarket supplier maintains:

- Precise Geometry: Exact dimensional match to OEM specifications for proper fitment.

- Correct Alloy: Metallurgy specifically engineered or cross-referenced for your application.

- Stringent Quality Control: Consistent casting integrity, hardness, and heat treatment.

It is paramount that the fixing systems, weight, and critical dimensions of aftermarket

blow bars precisely match the original specifications to ensure proper rotor balance,

prevent uneven wear, and maintain safe, reliable crusher operation. ATF specializes in

engineering aftermarket parts that often meet or exceed OEM performance for leading brands like Metso NP1213 blow bars and Sandvik QI442 wear parts equivalent .

Are blow bars interchangeable between different crusher models?

Generally, HSI blow bars are specifically designed and engineered for each unique crusher

model and rotor configuration. While some models from the same manufacturer or similar