HSI Impact Crusher Parts — Complete Wear Components

Complete range of horizontal shaft impact crusher wear parts: blow bars, impact plates, apron liners, side wear liners, rotor assemblies, and hardware kits. Available in martensitic steel, high chrome, and ceramic MMC alloys. Compatible with Metso NP, Kleemann MR, Sandvik QI, Trakpactor, McCloskey, Hazemag, and all major HSI brands.

- 35+Years Experience

- 500+Global Customers

- 50+Countries Served

Your Source for HSI Impact Crusher Parts

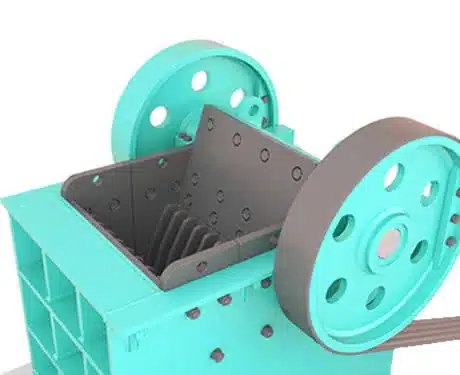

Horizontal shaft impact crushers require precision-engineered wear components to maintain product quality and throughput. We manufacture and supply the complete range of HSI wear parts including blow bars, apron liners, curtain plates, side wear liners, rotor assemblies, and hardware packages.

Our aftermarket HSI parts are compatible with all major brands including Metso, Sandvik, Hazemag, Kleemann, Terex, and McCloskey. We provide OEM reference cross-matching, technical support for material selection, and global logistics to minimize your downtime.

HSI Crusher Wear Parts — Full Range

Select the component you need. Click through for detailed specifications, material options, and pricing.

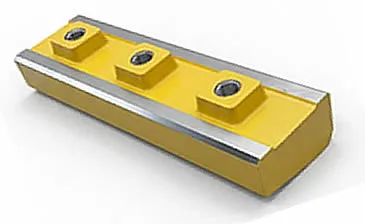

Blow Bars

Strike faces that determine output gradation and wear life. Multiple alloy options for different applications.

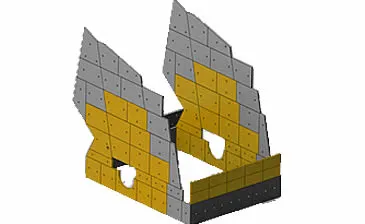

Impact Plates & Apron Liners

Secondary reduction surfaces that shape final product. Controls CSS and reduction ratio.

Side Wear Liners

Protects crusher housing from impact and abrasion. Interlocking segments for easy replacement.

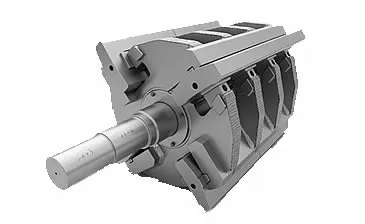

Rotor Assemblies & Shafts

Complete rotor packages with balancing and rebuild services. ISO-grade balancing available.

Clamps, Wedges & Hardware

Blow bar retention systems, liner hardware, and complete fastener kits per changeout.

Complete Wear Kits

Full blow bar set, impact plates, side liners, and hardware in one shipment. Package pricing available.

Material options: Blow bars available in martensitic steel, high chrome, and ceramic MMC. See detailed material guide on Blow Bars page →

HSI Crusher Parts Gallery

Complete range of wear components for horizontal shaft impact crushers

Material Selection Overview

HSI impact crusher parts require different alloys depending on whether the component sees primarily impact, abrasion, or combined loading.

Impact-Dominant Components

Blow bars are available in martensitic steel, high chrome, and ceramic MMC depending on feed type and tramp metal risk.

Impact + Abrasion Components

Curtain and apron liners typically use austenitic manganese or martensitic steel depending on crushing stage.

Abrasion-Dominant Components

Side wear liners use austenitic manganese or bimetallic construction for sliding contact wear resistance.

Structural Integrity

Rotor bodies, discs, and wedges require high-strength steel with proper heat treatment and NDT verification.

Compatible with All Major HSI Brands

We reverse-engineer and manufacture parts for horizontal shaft impactors from all major OEMs. Send us your model number or part reference for exact fitment confirmation.

- NP1110, NP1213, NP1315, NP1415, NP1520, NP1620, NP2023

NW Series portable models also supported

- MR 100(i) NEO, MR 110 EVO2, MR 130 EVO2, MR 130 PRO, MR 150

- Trakpactor 230/230SR, 260/260SR, 290/290SR, 320/320SR, 550/550SR

- I-100, IC-100, IC-110/IC-110RS, I-120, I-130, I-140

- I34/I34R, I44v3, I54v3, I4C, I3C

- APK Primary, APS Secondary, APP Tertiary

Provide exact sub-model in RFQ for precise fit

- R3, R4, R5, R6, I4e

Other Major Brands

- Rubble Master (RM Series)

- Rockster (R Series)

- Eagle Crusher (UltraMax)

- KPI-JCI (Andreas)

- Telsmith

Custom reverse-engineering available for any model

Don’t see your model? We can reverse-engineer from sample, drawing, or OEM reference number.

Blow Bar Parts Lookup

Search by brand → impact crusher series → model to view compatible blow bars and related wear parts.

Blow Bar Compatibility Reference

| Brand | Model | Reference | Material | Weight |

|---|---|---|---|---|

| Eagle | 1000 (UM-15) | 1000 (UM-15) | Martensitic; High Chrome; Ceramic Inserts | 240.000 |

| Eagle | 1200 (UM-25) | 1200 (UM-25) | Martensitic; High Chrome; Ceramic Inserts | 280.000 |

| Eagle | 1400 (UM-45) | 1400 (UM-45) | Martensitic; High Chrome; Ceramic Inserts | 315.000 |

| Eagle | 1600 (UM-69) | 1600 (UM-69) one piece | Martensitic; High Chrome; Ceramic Inserts | 590.000 |

| Eagle | 500 (UM-05) | 500 (UM-05) | Martensitic; High Chrome; Ceramic Inserts | 155.000 |

| Hartl | 1060 | 1060 | Martensitic; High Chrome; Ceramic Inserts | 192.000 |

| Hartl | 1270 | 1270 | Martensitic; High Chrome; Ceramic Inserts | 245.000 |

| Hartl | 1310 | 1310 | Martensitic; High Chrome; Ceramic Inserts | 355.000 |

| Hazemag | AP-PM 1822 | AP-PM 1822 | Martensitic; High Chrome; Ceramic Inserts | 865.000 |

| Hazemag | AP-PM 2225 | AP-PM 2225 | Martensitic; High Chrome; Ceramic Inserts | 1300.000 |

| Hazemag | AP-S 0813 | AP-S 0813 | Martensitic; High Chrome; Ceramic Inserts | 53.000 |

| Hazemag | APK1013 | APK1013 | Martensitic; High Chrome; Ceramic Inserts | 295.000 |

| Hazemag | APK105 | APK105 | Martensitic; High Chrome; Ceramic Inserts | 112.000 |

| Hazemag | APK40 | HAZ789 | Martensitic; High Chrome; Ceramic Inserts | 83.000 |

| Hazemag | APK50 | HAZ791 | Martensitic; High Chrome; Ceramic Inserts | 150.000 |

| Hazemag | APK60 | HAZ 850A | Martensitic; High Chrome; Ceramic Inserts | 182.000 |

| Hazemag | APP1013 | APP1013 | Martensitic; High Chrome; Ceramic Inserts | 256.000 |

| Hazemag | HAZ1013 | HAZ1013 | Martensitic; High Chrome; Ceramic Inserts | 300.000 |

| Hazemag | HAZ1036 | HAZ1036 | Martensitic; High Chrome; Ceramic Inserts | 270.000 |

| Hazemag | HAZ790 | HAZ790 | Martensitic; High Chrome; Ceramic Inserts | 115.000 |

| Hazemag | HAZ793 (2 grooves)- M3717454 | HAZ793 -M3717454 | Martensitic; High Chrome; Ceramic Inserts | 115.000 |

| Hazemag | HPI2025 | HPI2025 | Martensitic; High Chrome; Ceramic Inserts | 946.000 |

| Hazemag | M0172990 | M0172990 | Martensitic; High Chrome; Ceramic Inserts | 237.000 |

| Hazemag | M0174348 | M0174348 | Martensitic; High Chrome; Ceramic Inserts | 275.000 |

| Hazemag | M1022/APS1313/AP-PH1214 | M1022/APS1313/AP-PH1214 | Martensitic; High Chrome; Ceramic Inserts | 420.000 |

| Hazemag | M596 | M596 | Martensitic; High Chrome; Ceramic Inserts | 9.700 |

| Hazemag | MOD 686 | MOD 686 | Martensitic; High Chrome; Ceramic Inserts | 57.000 |

| Inertia | 4048 | 4048 | Martensitic; High Chrome; Ceramic Inserts | 308.000 |

| Inertia | 5066 | 5066 | Martensitic; High Chrome; Ceramic Inserts | 425.000 |

| Irock | S3151-13-4 | S3151-13-4 | Martensitic; High Chrome; Ceramic Inserts | 385.000 |

| Irock | S3151-13-5 | S3151-13-5 | Martensitic; High Chrome; Ceramic Inserts | 308.000 |

| Keestrack | Destroyer 1112,1113 | Destroyer 1112,1113 | Martensitic; High Chrome; Ceramic Inserts | 250.000 |

| Keestrack | R3 | R3 | Martensitic; High Chrome; Ceramic Inserts | 215.000 |

| Keestrack | R3 NEW | R3 NEW | Martensitic; High Chrome; Ceramic Inserts | 230.000 |

| Keestrack | R5 | R5 | Martensitic; High Chrome; Ceramic Inserts | 275.000 |

| Keestrack | R5 NEW | R5 NEW | Martensitic; High Chrome; Ceramic Inserts | 270.000 |

| Keestrack | R6 KP | R6 KP | Martensitic; High Chrome; Ceramic Inserts | 320.000 |

| Keestrack | R6 KT (Destroyer) | R6 KT (Destroyer) | Martensitic; High Chrome; Ceramic Inserts | 306.000 |

| Kleeman | MR-130 Z/R | 10665-2 | Martensitic; Martensitic+Ceramic; High Chrome; Other materials on request | 564.000 |

| Kleemann | MR100Z/ SHB10 (X shape) | MR100Z/ SHB10 (X shape) | Martensitic; High Chrome; Ceramic Inserts | 250.000 |

| Kleemann | MR110Z EVO (C shape) | MR110Z EVO (C shape) | Martensitic; High Chrome; Ceramic Inserts | 275.000 |

| Kleemann | MR122Z /SHB12 (X shape) | MR122Z /SHB12 (X shape) | Martensitic; High Chrome; Ceramic Inserts | 318.000 |

| Kleemann | MR130Z EVO (C shape) | MR130Z EVO (C shape) | Martensitic; High Chrome; Ceramic Inserts | 360.000 |

| Kleemann | MR130Z/SHB13 (S shape) | MR130Z/SHB13 (S shape) | Martensitic; High Chrome; Ceramic Inserts | 367.000 |

| Kleemann | MR150Z (C shape) | MR150Z (C shape) | Martensitic; High Chrome; Ceramic Inserts | |

| Kleemann | MR150Z (X shape) | MR150Z (X shape) | Martensitic; High Chrome; Ceramic Inserts | 440.000 |

| Kleemann | SHB14 | SHB14 | Martensitic; High Chrome; Ceramic Inserts | 370.000 |

| KPI-JCI(ASTEC) | FT4240 | FT4240 | Martensitic; High Chrome; Ceramic Inserts | 177.000 |

| KPI-JCI(ASTEC) | FT4250 | FT4250 | Martensitic; High Chrome; Ceramic Inserts | 230.000 |

| KPI-JCI(ASTEC) | FT5260 | FT5260 | Martensitic; High Chrome; Ceramic Inserts | 399.000 |

| Lippmann | 4248 | 4248 | Martensitic; High Chrome; Ceramic Inserts | 270.000 |

| Lippmann | 5165 | 5165 | Martensitic; High Chrome; Ceramic Inserts | 375.000 |

| McCloskey | I34 | I34 | Martensitic; High Chrome; Ceramic Inserts | 155.000 |

| McCloskey | I44 | I44 | Martensitic; High Chrome; Ceramic Inserts | 215.000 |

| McCloskey | I4C | I4C | Martensitic; High Chrome; Ceramic Inserts | 305.000 |

| McCloskey | I54 | I54 | Martensitic; High Chrome; Ceramic Inserts | 370.000 |

| Metso | NP-LT 1007 | NP-LT 1007 | Martensitic; High Chrome; Ceramic Inserts | 140.000 |

| Metso | NP-LT 1110 | NP-LT 1110 | Martensitic; High Chrome; Ceramic Inserts | 220.000 |

| Metso | NP-LT 1213/1313 (NP13) | N62252515 | Manganese; Martensitic; High Chrome; Ceramic Inserts | 335.000 |

| Metso | NP-LT 1213/1313 (NP13) | NP-LT 1213/1313 (NP13) | Martensitic; High Chrome; Ceramic Inserts | 325.000 |

| Metso | NP-LT 1315/1415 (NP15) | NP-LT 1315/1415 (NP15) | Martensitic; High Chrome; Ceramic Inserts | 445.000 |

| Metso | NP1520/1620 | NP1520/1620 | Martensitic; High Chrome; Ceramic Inserts | 730.000 |

| Portafill | 7000-IC Full | 7000-IC Full | Martensitic; High Chrome; Ceramic Inserts | 144.000 |

| Rockster | R700 | R700 | Martensitic; High Chrome; Ceramic Inserts | 128.000 |

| Rockster | R900 | R900 | Martensitic; High Chrome; Ceramic Inserts | 175.000 |

| Rubblemaster | RM100 | RM100 | Martensitic; High Chrome; Ceramic Inserts | 175.000 |

| Rubblemaster | RM120 | RM120 | Martensitic; High Chrome; Ceramic Inserts | 275.000 |

| Rubblemaster | RM60 | RM60 | Martensitic; High Chrome; Ceramic Inserts | 71.000 |

| Rubblemaster | RM70 | RM70 | Martensitic; High Chrome; Ceramic Inserts | 93.000 |

| Rubblemaster | RM80/90 | RM80/90 | Martensitic; High Chrome; Ceramic Inserts | 136.000 |

| Sandvik | CI124 | CI124 | Martensitic; High Chrome; Ceramic Inserts | 218.000 |

| Sandvik | CI224 | CI224 | Martensitic; High Chrome; Ceramic Inserts | 436.000 |

| Sandvik | QI340 (Extec I-C13, APP1013) | QI340 (Extec I-C13, APP1013) | Martensitic; High Chrome; Ceramic Inserts | 256.000 |

| Sandvik | QI341 (QI240) | QI341 (QI240) | Martensitic; High Chrome; Ceramic Inserts | 230.000 |

| Sandvik | QI353 | QI353 | Martensitic; High Chrome; Ceramic Inserts | 312.000 |

| Sandvik | QI441 (QI440) | QI441 (QI440) | Martensitic; High Chrome; Ceramic Inserts | 345.000 |

| SBM | 10.6.4 | 10.6.4 | Martensitic; High Chrome; Ceramic Inserts | 119.000 |

| SBM | 1311/1313 | 1311/1313 | Martensitic; High Chrome; Ceramic Inserts | 345.000 |

| SBM | REMAX 200 | REMAX 200 | Martensitic; High Chrome; Ceramic Inserts | 194.000 |

| SBM | REMAX 300 | REMAX 300 | Martensitic; High Chrome; Ceramic Inserts | 229.000 |

| SBM | REMAX 400 | REMAX 400 | Martensitic; High Chrome; Ceramic Inserts | 275.000 |

| Striker | 1112/1312 | 1112/1312 -100mm | Martensitic; High Chrome; Ceramic Inserts | 338.000 |

| Striker | 1112/1312 | 1112/1312 -120mm | Martensitic; High Chrome; Ceramic Inserts | 400.000 |

| Striker | 1315 | 1315 | Martensitic; High Chrome; Ceramic Inserts | 460.000 |

| Striker | 907 | 907 | Martensitic; High Chrome; Ceramic Inserts | 160.000 |

| Terex Cedarapids | 5048 HIS | 5048 HIS | Martensitic; High Chrome; Ceramic Inserts | 365.000 |

| Terex Cedarapids | 5064 HIS | 5064 HIS | Martensitic; High Chrome; Ceramic Inserts | 240.000 |

| Terex Evoquip | Cobra 230/260 | Cobra 230/260 | Martensitic; High Chrome; Ceramic Inserts | 140.000 |

| Terex Evoquip | Cobra 230/260 (Short/Half) | Cobra 230/260 (Short/Half) | Martensitic; High Chrome; Ceramic Inserts | 116.000 |

| Terex Evoquip | Cobra 290 | Cobra 290 | Martensitic; High Chrome; Ceramic Inserts | 190.000 |

| Terex Finlay | I-100 (IC-100) | I-100 (IC-100) | Martensitic; High Chrome; Ceramic Inserts | 140.000 |

| Terex Finlay | I-110 (I-1310) | I-110 (I-1310) | Martensitic; High Chrome; Ceramic Inserts | 187.000 |

| Terex Finlay | I-120 | I-120 | Martensitic; High Chrome; Ceramic Inserts | 214.000 |

| Terex Finlay | I-130 | I-130 | Martensitic; High Chrome; Ceramic Inserts | 365.000 |

| Terex Finlay | I-140 | I-140 | Martensitic; High Chrome; Ceramic Inserts | 377.000 |

| Terex Finlay | IC110 | IC110 | Martensitic; High Chrome; Ceramic Inserts | 190.000 |

| Terex Powerscreen | Pegson 1412 tracpactor (Hazemag chamber) | Pegson 1412 tracpactor (Hazemag chamber) | Martensitic; High Chrome; Ceramic Inserts | 425.000 |

| Terex Powerscreen | Pegson 428 | Pegson 428 | Martensitic; High Chrome; Ceramic Inserts | 206.000 |

| Terex Powerscreen | Trakpactor 320 (New clamped) | Trakpactor 320 (New clamped) | Martensitic; High Chrome; Ceramic Inserts | 214.000 |

| Terex Powerscreen | Trakpactor 320 (Old clamped) | Trakpactor 320 (Old clamped) | Martensitic; High Chrome; Ceramic Inserts | 215.000 |

| Terex Powerscreen | Trakpactor 550 (Hazemag chamber) | Trakpactor 550 (Hazemag chamber) | Martensitic; High Chrome; Ceramic Inserts | 425.000 |

| Terex Powerscreen | Trakpactor 550 (Terex chamber) | Trakpactor 550 (Terex chamber) | Martensitic; High Chrome; Ceramic Inserts | 390.000 |

| Terex Powerscreen | XH250 | XH250 | Martensitic; High Chrome; Ceramic Inserts | 140.000 |

| Terex Powerscreen | XH320 (unclamped) | XH320 (unclamped) | Martensitic; High Chrome; Ceramic Inserts | 215.000 |

| Tesab | RK1012 | RK1012 | Martensitic; High Chrome; Ceramic Inserts | 192.000 |

| Tesab | RK623/624 | 2-320 | Martensitic; High Chrome; Ceramic Inserts | 104.000 |

This static list is a subset for quick reference. Use the filters above for the full, up-to-date catalog.

Rotor Maintenance & Rebuild Services

HSI rotor assemblies are critical to crusher performance. We provide inspection, repair, balancing, and complete rebuild services to extend rotor life and maintain safe operation.

Inspection Services

- Visual inspection: Crack detection, wear assessment, hardware condition

- NDT testing: Magnetic particle, dye penetrant, ultrasonic as needed

- Runout measurement: Shaft straightness, disc alignment verification

- Report: Detailed findings with repair recommendations and estimated costs

Rebuild Services

- Welding repairs: Crack repair, buildup of worn seating surfaces

- Machining: Re-face rotor body, true mounting surfaces

- Component replacement: New discs, wedges, keys as required

- Final balancing: Dynamic balancing per ISO 1940-1 standards

Balancing Requirements

Proper rotor balance is critical for bearing life, vibration control, and safe operation. We perform dynamic balancing to G6.3 grade or better.

- Rotor speed range: 450–1200 RPM typical

- Residual unbalance: ≤10 g-mm/kg maximum

- Documentation: Balance report with before/after readings

Emergency Services

Rotor failure can cause extended downtime. We maintain stock rotor assemblies for common models and offer expedited rebuild services.

- Exchange programs: Pre-balanced spare rotors available

- Rush service: 48–72 hour turnaround for critical repairs

- Field service: On-site inspection and repair capabilities

Need rotor inspection or rebuild? Send photos and model information for preliminary assessment.

Installation Guidelines & Safety

Proper installation procedures ensure safe operation and optimal wear life. Always follow OEM manuals and site-specific safety protocols.

Pre-Installation Checklist

- Complete LOTO procedure, verify zero energy state

- Inspect all lifting equipment and certified lifting tools

- Clean all seating surfaces thoroughly before installation

- Check blow bar weights — ensure matched set for balance

- Verify hardware grade matches OEM specifications

- Have torque wrench calibrated and available

Blow Bar Installation

- Use certified lifting tools designed for blow bars

- Install bars in correct sequence per OEM manual

- Verify seating faces are flat and fully supported

- Torque wedges to specification

- Re-torque after 1-2 hours of warm-up operation

- Confirm rotor balance before full-speed operation

Impact Plate Installation

- Verify S1/S2 gap settings before and after installation

- Check hydraulic cylinder function if equipped

- Ensure proper backing support behind plates

- Use correct grade fasteners and torque values

- Verify curtain alignment and clearances

Side Liner Installation

- Install interlocking segments in correct sequence

- Verify door clearances and seal integrity

- Check for proper fit without forcing or gaps

- Inspect mounting points for wear or damage

- Torque all fasteners to specification

Troubleshooting Common HSI Problems

Identifying wear patterns early helps prevent catastrophic failure and optimize part life.

❌ Uneven Wear Pattern

Symptom: One side of rotor wears 30-50% faster than other side

Common Causes:

- Off-center feed distribution

- Asymmetric S1/S2 curtain settings

- Worn feed chute deflecting material

Solutions:

- Center feed stream using chute adjustments

- Measure and match S1/S2 gaps within ±2mm

- Rotate bar positions every 200-300 hours

⚠️ Excessive Product Fines

Symptom: Product gradation shifts toward fines over time

Common Causes:

- Blow bar edge rounding past optimal point

- Rotor speed too high for application

- S1 gap too tight

Solutions:

- Flip or replace blow bars

- Reduce rotor speed 10-15%

- Open S1 gap in 5mm increments

🔧 Vibration or Noise

Symptom: Unusual vibration or rattling during operation

Common Causes:

- Loose blow bar wedges or hardware

- Rotor imbalance from worn bars

- Damaged bearings

Solutions:

- Stop immediately and inspect wedge torque

- Replace worn bars in matched sets

- Check bearing condition and lubrication

📉 Rapid Wear on New Parts

Symptom: Parts wearing 50-70% faster than expected

Common Causes:

- Wrong alloy selection for feed type

- Excessive rotor speed

- High fines content in feed

Solutions:

- Review alloy selection vs feed characteristics

- Install pre-screen to remove fines below 10mm

- Reduce tip speed; monitor product gradation

HSI Parts — FAQs

What are the main wear parts in an HSI crusher?

The primary wear parts are blow bars (rotor strike faces), impact/apron plates (curtain liners), side wear liners (frame protection), and rotor assemblies. Hardware including wedges, clamps, and fasteners also require periodic replacement.

How often should I replace HSI crusher parts?

Replacement intervals vary by application:

- Blow bars: Varies by material and feed type

- Impact plates: Typically 2-3× blow bar life

- Side liners: Typically 3-5× blow bar life

- Rotor rebuild: Every 3-5 years or per wear assessment

Always inspect regularly and replace before reaching wear limits.

Can I mix different manufacturers’ parts on my HSI?

Blow bars must be matched sets (same alloy and weight within 3%) to maintain rotor balance. Impact plates and side liners can typically be mixed if dimensions match. Always verify fitment and consult your service manual before mixing parts from different suppliers.

What’s included in a complete HSI wear kit?

A complete wear kit typically includes full blow bar set, all impact/apron plates, complete side liner set, and hardware package (wedges, clamps, fasteners). Kits are sized for major maintenance shutdowns and include estimated service hours based on typical applications.

How do I determine the right material for my application?

Material selection depends on feed type (hard rock vs. recycled concrete), abrasiveness (silica content), impact level (primary vs. secondary duty), and contamination (tramp metal risk). See our detailed blow bar material guide or contact us with your feed details for specific recommendations.

Do you offer rotor balancing services?

Yes, we provide dynamic balancing per ISO 1940-1 standards (G6.3 grade or better). Services include rotor inspection, crack repair, component replacement, machining, and final balancing with documentation. We also offer exchange programs for common models and 48-72 hour rush service.

Are your parts compatible with OEM equipment?

Yes. We manufacture parts compatible with all major HSI brands including Metso NP, Kleemann MR, Sandvik QI, Trakpactor, McCloskey, Hazemag, and more. All parts are reverse-engineered to match OEM specifications. Send your model number for compatibility confirmation.

What is the typical lead time for HSI parts?

Standard blow bar sets: 3-5 weeks. Common spare parts: 2-4 weeks from stock. Complete wear kits: 4-6 weeks. Rush orders available for emergency situations. Contact us for current availability.

Get Your Custom Quote in 24-48 Hours

Expert guidance for your HSI crusher parts needs. No hassle, no sales pressure.

35+ years serving mining & aggregate operations

Prefer a different method?

Email: [email protected]

Phone: +1 308 465 1950

What Happens Next?

-

1

Instant Confirmation

You’ll receive a confirmation message immediately

-

2

Expert Review

Our technical team analyzes your requirements

-

3

Custom Quote

Receive detailed pricing within 24 hours

Serving aggregate, mining & cement industries

OEM-compatible parts with technical support

Your information is protected and never shared

“ATF delivered exactly what we needed. Fast response, competitive pricing, and parts that lasted 30% longer than our previous supplier.”

— Operations Manager, Chilean Mining Company

Meet Our HSI Impact Crusher Parts Engineering Experts

Our team of metallurgical and applications engineers is dedicated to optimizing your impact crushing performance and reducing your cost per ton.

Bao Xiuru

Product Manager, HSI Wear Parts — 18+ years optimizing blow bar alloys and designs for maximum wear life in aggregate & recycling plants.

Zhang Lin

Senior Foundry Engineer — Over 20 years of hands-on experience in the advanced casting and heat treatment of martensitic and high-chrome blow bars.

Industries We Serve

Mining & Quarrying

Engineered wear parts for high-tonnage operations in hard rock mining, iron ore, copper, and gold extraction.

Aggregates Production

Optimized crusher parts for consistent product gradation in sand, gravel, and crushed stone operations.

Recycling & C&D

Rebar-tolerant wear parts for concrete recycling, asphalt reclamation, and demolition waste processing.

Cement Production

Reliable wear parts for continuous-duty limestone crushing in cement plants and lime operations.

Complete Your Crushing Circuit

Browse our full range of crusher wear parts

HSI Blow Bars

Detailed specifications, material options, and application guidance for impact crusher blow bars.

Cone Crusher Liners

Mantles and concaves for secondary and tertiary crushing applications.