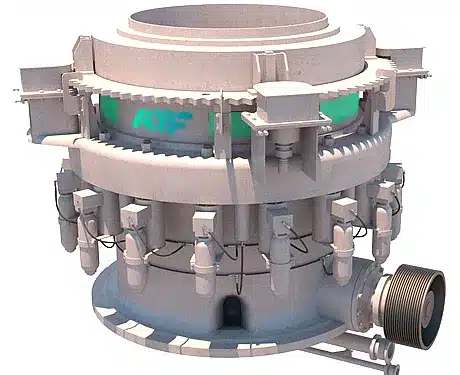

Cone Crusher Parts — Mantles, Bowl Liners & Components

Complete range of cone crusher wear and spare parts: mantles, bowl/concave liners, torch rings, feed cones, socket liners, eccentric assemblies, bearings, adjustment systems, seals, and hardware kits. Available in Mn13/Mn18/Mn22 manganese grades with optional TiC inserts. Compatible with Metso HP/GP, Sandvik CH/CS, Symons, Telsmith, and all major brands.

- 35+Years Experience

- 500+Global Customers

- 50+Countries Served

Your Complete Cone Crusher Parts Source

Cone crushers are the workhorses of secondary and tertiary circuits, requiring precision-engineered wear parts and reliable spare components. We manufacture and supply the complete range: mantles, bowl/concave liners, torch rings, feed cones, socket liners, eccentric assemblies, bearings, adjustment systems, seals, and hardware kits.

Our parts are compatible with all major brands including Metso Nordberg HP/GP series, Sandvik CH/CS, Symons, Telsmith, Terex, and Trio. Each component is dimensionally verified, metallurgically matched to your application, and backed by technical support to minimize downtime and optimize cost per ton.

Cone Crusher Wear Parts

Select the wear component you need. Click through for detailed specifications, material options, and pricing.

Mantles

Head liner that moves eccentrically to crush material. Available in coarse, medium, and fine chamber profiles.

Bowl / Concave Liners

Fixed liner in bowl assembly that shapes product. One-piece, two-piece, and segmented designs available.

Torch Rings & Feed Cones

Protects feed opening from abrasion and impact. Also called burning rings. High-manganese construction.

Material options: All wear parts available in Mn13, Mn18, Mn22 manganese grades with optional TiC insert reinforcement. See detailed material guide →

Cone Crusher Spare Parts — Complete Range

OEM-compatible spare and wear components for Metso Nordberg HP/GP, Sandvik CH/CS, Symons, Telsmith, Terex, Trio and more. All parts are traceable, dimensionally checked, and can be supplied as kits.

Head & Mainshaft Assembly

Head Assembly

- Head assembly / head center / head ball

- Mainshaft (standard & short head)

- Upper & lower head bushings

- Water baffle & head wiper ring

Socket & Socket Liner

- Socket assemblies

- Bronze socket liners

- Seals & O-rings kit

- Socket bushing & thrust plate

Step & Thrust Bearings

- Upper / lower thrust bearings & washers

- Step bearing plates & piston wear rings

- Spacer sets & shims

- Bearing covers & seals

Eccentric & Drive System

Eccentric Assembly

- Eccentric assemblies

- Inner / outer eccentric bushings

- Eccentric wear rings

- Eccentric locking assemblies

Countershaft & Gears

- Countershaft, box & bushings

- Gear & pinion sets

- Countershaft guards

- Lubrication lines & fittings

Drive Components

- Counterweight & guards

- Motors, pulleys & belts (select models)

- V-belt guards & tensioning systems

- Drive sheaves & keys

Adjustment & Bowl System

Adjustment Ring & Clamp

- Adjustment ring & clamp ring

- Clamping cylinders & hydraulic adjustment motor

- Bowl assembly & bowl bolts

- Lock posts (hydraulic / Duckworth)

Tramp Release System

- Tramp release cylinders & accumulators

- Relief valves & hydraulic hoses

- Pressure switches & sensors

- Nitrogen charging kits

Bowl & Frame

- Bowl liner retaining rings

- Concave filler rings (where applicable)

- Bowl support ring

- Mainframe arm guards & liners

Seals & Dust Protection

Dust Seal System

- Dust seal rings & retainers

- T-seals / O-ring kits

- Gaskets, wear sleeves & boots

- Labyrinths & deflectors

Lubrication System

- Oil pumps, coolers & filters

- Lubrication lines & manifolds

- Temperature & pressure sensors

- Oil sight glasses & drain valves

Hardware & Fasteners

- Locking bolts & nuts, studs & washers

- Lifting eyes & tools (mantle & concave)

- Backing compound (epoxy) & kits

- Complete seal & maintenance kits

Not sure what you need? Send your crusher model and part number (or a photo) and we’ll match the parts one-to-one.

Cone Crusher Parts Gallery

Complete range of wear and spare components

Material Selection Overview

Cone crusher liners require compression-resistant materials that work-harden under load. Select manganese grade based on impact level and abrasiveness.

Mn13 Grade

Traditional choice for variable feed with lower abrasion and moderate impact. Cost-effective baseline option.

Mn18 Grade

Industry standard for most operations. Better work-hardening capacity than Mn13 with improved wear life.

Mn22 Grade

Highest work-hardening response for severe impact and variable feed sizes. Primary crushing duty.

Mn + TiC Inserts

TiC reinforcement extends edge life while maintaining manganese toughness. Abrasive hard rock applications.

Ceramic MMC

Maximum wear life potential in controlled, clean feed applications. Requires consistent feed conditions.

Need Help Selecting?

Our detailed material guide covers chemical compositions, wear characteristics, and application matching.

Compatible with All Major Cone Crusher Brands

We reverse-engineer and manufacture parts for cone crushers from all major OEMs. Send us your model number or part reference for exact fitment confirmation.

- HP100, HP200, HP300, HP400, HP500, HP700, HP800

- GP100, GP200, GP300, GP500, GP550

Complete parts coverage: liners, bearings, eccentrics, seals

- CH420, CH430, CH440, CH660, CH870, CH880, CH895

- CS420, CS430, CS440, CS660

Hydrocone and legacy models also supported

- 2ft, 3ft, 4.25ft Standard/Short Head

- 5.5ft, 7ft models

Nordberg legacy and aftermarket parts

- SBS 4030, 5130, 7248, 8563

- Titan series

- RC Series (RC42, RC54, RC66)

- MVP Series

Other Major Brands

- Trio (TC/TP Series)

- KPI-JCI (Kodiak Plus)

- Eagle (UltraCone)

- FLSmidth (Fuller-Traylor)

Custom reverse-engineering for any model

Don’t see your model? We can reverse-engineer from sample, drawing, or OEM reference number.

Change-Out & Installation Guidelines

Proper installation procedures ensure safe operation and optimal wear life. Always follow OEM manuals and site-specific safety protocols.

Pre-Installation Checklist

- Complete LOTO procedure, verify zero energy

- Inspect all lifting equipment and certified lifting tools

- Clean seating surfaces and threads thoroughly

- Check backing compound expiration date

- Verify correct liner profile and alloy grade

- Have torque wrench calibrated and available

Mantle Installation

- Use certified lifting tools for mantle weight

- Clean head ball and mantle bore completely

- Heat mantle per OEM specifications (if required)

- Apply backing compound evenly, avoid air pockets

- Torque head nut to specification

- Verify mantle seating with feeler gauge

Bowl/Concave Installation

- Clean bowl seating surfaces thoroughly

- Apply backing compound per OEM instructions

- Install concaves in correct orientation

- Torque bowl bolts in star pattern to specification

- Re-torque after 4-8 hours of operation

- Verify CSS with lead impression or measurement

Warm-Up & Verification

- Run crusher empty for 15-30 minutes

- Check for unusual vibration or noise

- Start with light feed; gradually increase

- Monitor oil temperature and pressure

- Verify CSS setting under load

- Document installation date and hours

Troubleshooting Common Cone Crusher Problems

Identifying wear patterns and operational issues early helps prevent catastrophic failure and optimize part life.

❌ Rapid Top-Zone Wear

Symptom: Excessive wear in upper portion of liners; increasing fines production

Common Causes:

- CSS set too open for feed size

- Poor choke feed distribution

- Insufficient material in chamber

Solutions:

- Re-establish proper choke feed condition

- Close CSS in small increments (2-3mm)

- Consider thicker top-zone liner design

⚠️ Edge Rounding & Polishing

Symptom: Liner edges become rounded; product curve shifts coarser

Common Causes:

- Abrasive feed with high contact pressure

- CSS too close for material hardness

- Standard Mn13 in very abrasive duty

Solutions:

- Upgrade to Mn18 or Mn22 grade

- Add TiC insert reinforcement at edges

- Review chamber selection (coarse vs. fine)

🔧 Cracking or Chipping

Symptom: Cracks visible in liner surface; chunks breaking off

Common Causes:

- Tramp metal impacts

- Improper seating (voids in backing)

- Thermal shock from water spray

Solutions:

- Improve metal detection and removal

- Verify proper backing compound application

- Upgrade to Mn22 for severe impact duty

📉 Uneven Wear Pattern

Symptom: Wear concentrated in one area; irregular product size

Common Causes:

- Imbalanced feed distribution

- Head/bowl misalignment

- Worn eccentric bushings

Solutions:

- Stabilize feed distribution system

- Check head alignment; inspect thrust bearings

- Replace worn eccentric bushings

Quick Calculator — Estimate Life Gain & Cost per Ton

Enter your current average life and an expected improvement factor. Results are indicative and help compare options.

Cone Crusher Parts — FAQs

What’s the difference between a mantle and a bowl/concave liner?

The mantle is the moving liner attached to the head, which gyrates eccentrically. The bowl/concave is the stationary liner in the bowl assembly. Together they form the crushing chamber where material is compressed and broken.

When should I rotate or replace cone liners?

Replace liners when:

- Wear approaches minimum thickness limit (typically 70-75% worn)

- Product size distribution drifts significantly

- Power draw increases noticeably

- Visual inspection shows excessive wear or cracking

Replace before exposing seating surfaces to prevent damage to bowl and head.

What materials should I use for cone crusher liners?

Cone crushers require austenitic manganese steel (Mn13/Mn18/Mn22) which work-hardens under compression. Never use high-chrome white iron or materials designed for impact crushers. Optional TiC inserts can extend life in suitable applications. See detailed material guide →

Mn + TiC vs standard manganese — which should I choose?

TiC-reinforced manganese improves edge retention while maintaining impact toughness—good for hard, abrasive rock with variable feed. Standard manganese (Mn18/Mn22) is appropriate for moderate abrasion or when TiC cost premium isn’t justified. Choose based on your specific feed characteristics and wear patterns.

What spare parts should I keep in stock?

Recommended spare parts inventory:

- Critical: Mantle and concave set, socket liner, eccentric bushing set

- Important: Torch ring, feed cone, seal kits, hardware

- Consider: Thrust bearings, countershaft bushings, tramp release seals

Stock levels depend on crusher criticality and lead times. Contact us for inventory planning assistance.

How do I choose between coarse, medium, and fine chamber profiles?

Chamber selection depends on feed size and target product:

- Coarse: Larger feed (up to full feed opening), coarser product, higher throughput

- Medium: Balanced feed/product, most versatile

- Fine: Smaller feed, finer product, shaping applications

Are your parts compatible with OEM equipment?

Yes. We manufacture parts compatible with all major brands including Metso HP/GP, Sandvik CH/CS, Symons, Telsmith, Terex, and more. All parts are reverse-engineered to match OEM specifications for proper fit. Send your model number for compatibility confirmation.

What is the typical lead time for cone crusher parts?

Standard liner sets: 4-6 weeks. Common spare parts: 2-4 weeks from stock. Custom or specialized items: 6-8 weeks. Rush orders available for emergency situations. Contact us for current availability.

Get Your Custom Quote in 24-48 Hours

Expert guidance for your cone crusher parts needs. No hassle, no sales pressure.

35+ years serving mining & aggregate operations

Prefer a different method?

Email: [email protected]

Phone: +1 308 465 1950

What Happens Next?

-

1

Instant Confirmation

You’ll receive an email confirmation immediately

-

2

Expert Review

Our technical team analyzes your requirements

-

3

Custom Quote

Receive detailed pricing within 24 hours

Serving aggregate, mining & cement industries

OEM-compatible parts with technical support

Your information is protected and never shared

“ATF delivered exactly what we needed. Fast response, competitive pricing, and parts that lasted 30% longer than our previous supplier.”

— Operations Manager, Chilean Mining Company

Meet Our Cone Crusher Parts Engineering Experts

Our team of metallurgical and applications engineers is dedicated to optimizing your crushing performance and reducing your cost per ton.

Bao Xiuru

Product Manager — 18+ years optimizing cone crusher liner alloys and chamber profiles for aggregate & mining operations. Specializes in cost-per-ton reduction strategies.

Zhang Lin

Senior Foundry Engineer — Over 20 years of hands-on experience in the advanced casting and heat treatment of manganese steel cone liners.

Industries We Serve

Mining & Quarrying

Engineered wear parts for high-tonnage operations in hard rock mining, iron ore, copper, and gold extraction.

Aggregates Production

Optimized crusher parts for consistent product gradation in sand, gravel, and crushed stone operations.

Recycling & C&D

Durable wear parts for concrete recycling, asphalt reclamation, and demolition waste processing.

Cement Production

Reliable wear parts for continuous-duty limestone crushing in cement plants and lime operations.

Complete Your Crushing Circuit

Browse our full range of crusher wear parts

Cone Crusher Liners

Detailed specifications, material options, and chamber selection guide for mantles and concaves.

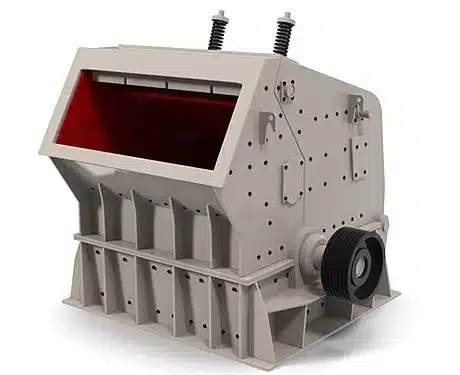

HSI Blow Bars

Impact crusher blow bars for aggregate, recycling, and mining applications.