Advanced Crusher Wear Materials — MMC & TiC Insert Technology

Metal Matrix Composites (MMC) and Titanium Carbide (TiC) inserts represent the two most significant advances in crusher wear technology. MMC embeds ceramic phases in a metallic matrix for 2-4× wear life improvement in abrasion-dominant applications. TiC inserts reinforce manganese steel edges for 40-60% longer service while maintaining impact toughness. Selection depends on duty class, shock environment, and contamination risk.

- 35+Years R&D

- 2-4×Wear Life Gain

- 500+Field Validations

Two Technologies, Different Purposes

Understanding when to use Metal Matrix Composites versus TiC-reinforced manganese is fundamental to optimizing wear costs. Each technology excels in specific conditions—misapplication leads to premature failure or unnecessary expense.

Metal Matrix Composites (MMC)

What it is: Ceramic particles or tiles embedded in a metallic matrix (martensitic steel or high-chrome iron), creating a composite wear surface.

How it works: Ultrahard ceramic phases (Al₂O₃, ZTA, or SiC) resist micro-cutting and erosive wear. The metal matrix provides structural support and distributes impact loads around the ceramic.

Best for: Secondary/tertiary crushing, VSI applications, recycling with clean feed—anywhere abrasion dominates and impact is moderate.

Performance: 2-4× wear life improvement vs. mono-alloy in suitable applications.

TiC-Reinforced Manganese

What it is: Titanium carbide rods or tiles metallurgically bonded to Hadfield manganese steel at high-wear zones (tooth crests, leading edges).

How it works: TiC inserts (hardness ~3,000 HV) resist abrasive wear at the edge while the manganese matrix absorbs impact energy through work-hardening.

Best for: Primary crushing, jaw plates, cone liners in abrasive ore, any application requiring shock tolerance with improved edge retention.

Performance: 40-60% wear life improvement vs. plain manganese while maintaining break resistance.

| Characteristic | MMC Composites | TiC-Reinforced Manganese |

|---|---|---|

| Primary Strength | Maximum abrasion resistance | Abrasion resistance + impact tolerance |

| Impact Tolerance | Moderate (matrix-dependent) | High (Mn matrix work-hardens) |

| Tramp Metal Risk | ⚠️ Ceramic can fracture | ✓ Mn absorbs shock |

| Typical Applications | HSI blow bars, VSI tips, secondary liners | Jaw plates, cone liners, primary impact |

| Wear Life Gain | 2-4× vs. mono-alloy | 1.4-1.6× vs. plain Mn |

| Cost Premium | 40-80% over standard | 25-50% over plain Mn |

| Break Risk | Higher if misapplied to shock duty | Low—Mn provides safety margin |

Metal Matrix Composite (MMC) Technology

Engineered ceramic-metal composites for maximum abrasion resistance in controlled-impact applications.

How MMC Wear Parts Work

Metal Matrix Composites position engineered ceramic phases at the wear interface where abrasive particles cause material removal. The ceramic—typically aluminum oxide (Al₂O₃), zirconia-toughened alumina (ZTA), or silicon carbide (SiC)—resists micro-cutting, gouging, and erosive wear far more effectively than any metallic alloy.

The metallic matrix surrounding and supporting the ceramic serves two functions: it provides structural integrity under impact loads, and it wears preferentially to expose fresh ceramic surfaces. This controlled differential wear maintains the composite’s abrasion resistance throughout its service life.

Matrix Selection

The matrix alloy determines impact tolerance and sets the floor for overall toughness:

- Martensitic steel matrix (HRC 50-55): Higher toughness for applications with moderate impact—recycling, secondary HSI, demolition concrete with some contamination.

- High-chrome iron matrix (HRC 58-63): Maximum abrasion resistance for low-impact, highly abrasive flows—VSI, tertiary crushing, manufactured sand.

- Ni-Hard matrix (HRC 55-60): Balance of wear resistance and impact tolerance for intermediate applications.

Ceramic Types & Properties

- Aluminum Oxide (Al₂O₃): Hardness ~1,800 HV. Cost-effective, good general abrasion resistance. Standard choice for most applications.

- Zirconia-Toughened Alumina (ZTA): Hardness ~1,600 HV with improved fracture toughness. Better impact tolerance than pure alumina.

- Silicon Carbide (SiC): Hardness ~2,500 HV. Maximum wear resistance for extreme abrasion. Higher cost, lower impact tolerance.

MMC Design Parameters

- Ceramic coverage: 40-70% of wear face depending on impact severity

- Tile thickness: 10-25mm based on expected wear depth

- Tile geometry: Hexagonal or rectangular for optimal packing and stress distribution

- Edge protection: Metallic margins at impact zones prevent ceramic edge chipping

Performance Expectations

| Application | Life vs. Standard |

|---|---|

| HSI blow bars (limestone) | 2.5-3.5× |

| HSI blow bars (granite) | 2.0-3.0× |

| VSI rotor tips | 2.0-4.0× |

| Secondary cone liners | 1.8-2.5× |

Best-Fit Applications for MMC

✓ Ideal for MMC

- Secondary/tertiary HSI crushing

- VSI manufactured sand production

- Clean concrete recycling

- Limestone and soft rock aggregate

- Consistent, controlled feed

⚠️ Use Caution

- Primary crushing (impact severity)

- Variable feed with occasional large pieces

- Mixed recycling with unknown contamination

- Operations with limited quality control

✗ Avoid MMC

- Heavy rebar contamination (>5%)

- Primary jaw or gyratory crushing

- Frequent tramp metal events

- Underground mining with steel support

Titanium Carbide (TiC) Insert Technology

Strategic carbide reinforcement for manganese steel—extending edge life while preserving impact toughness.

How TiC Reinforcement Works

Titanium carbide inserts are metallurgically bonded to Hadfield manganese steel during the casting process. The TiC (hardness ~3,000 HV, compared to ~200-280 HV for as-cast manganese) provides localized abrasion resistance at high-wear zones—tooth crests, leading edges, and nip areas—while the manganese matrix absorbs impact energy through its characteristic work-hardening behavior.

Unlike MMC where ceramic covers large areas, TiC inserts are strategically positioned only where abrasive wear is most severe. This targeted approach preserves the manganese steel’s bulk toughness while addressing its primary weakness: rapid edge rounding under abrasive conditions.

Insert Configurations

- TiC rods (Ø8-15mm): Embedded perpendicular to wear surface. Self-sharpening as surrounding Mn wears. Common for jaw plate teeth.

- TiC tiles (10-25mm thickness): Larger coverage areas for cone liner lips, impact bar edges. Higher initial cost but longer service.

- TiC strips: Linear reinforcement along high-wear edges. Cost-effective for moderate abrasion applications.

Manganese Grade Selection

The base manganese alloy is selected based on application severity:

- Mn13Cr2 + TiC: Softer ores, moderate impact. Lower cost baseline with good toughness margin.

- Mn18Cr2 + TiC: Standard hard rock applications. Balanced work-hardening and toughness. Most common selection.

- Mn22Cr2 + TiC: Highly abrasive ores, severe duty. Maximum work-hardening potential with TiC edge protection.

Critical Manufacturing Controls

- Insert positioning: Modeled for neutral-axis stress distribution to prevent edge chipping

- Metallurgical bonding: Controlled pour temperature (1,400-1,450°C) for diffusion bond without insert degradation

- Heat treatment: Solution treatment at 1,050-1,100°C with rapid water quench to prevent carbide precipitation

- Quality validation: Ultrasonic inspection of insert bonding, hardness mapping of heat-treated matrix

Performance Expectations

| Application | Life vs. Plain Mn |

|---|---|

| Jaw plates (abrasive ore) | 1.4-1.8× |

| Cone liners (porphyry copper) | 1.3-1.6× |

| Primary HSI blow bars | 1.3-1.5× |

| Hammer mill hammers | 1.4-1.7× |

Best-Fit Applications for TiC-Reinforced Manganese

✓ Ideal for TiC+Mn

- Primary jaw crushers in abrasive ore

- Cone crushers in mining applications

- Primary/roughing HSI positions

- High-impact with edge wear concern

- Operations with tramp metal risk

⚠️ Consider Alternatives

- Soft limestone (plain Mn sufficient)

- Very low abrasion feeds

- Extreme impact without abrasion

- Cost-sensitive operations with acceptable plain Mn life

✗ TiC Unnecessary

- Clean limestone aggregate

- Low-silica industrial minerals

- Short-run or trial applications

- When plain Mn achieves target life

Material Specifications & Standards

Detailed chemical compositions, mechanical properties, and testing standards for advanced crusher wear materials. This technical reference provides specification-level data for engineering evaluation.

Manganese Steel Grades

Hadfield manganese steels form the foundation for most crusher wear applications. Carbon and manganese content determine work-hardening potential and as-cast hardness.

| Grade | C (%) | Mn (%) | Cr (%) | Si (%) | As-Cast HB | Work-Hardened HB |

|---|---|---|---|---|---|---|

| Mn13Cr2 | 1.0-1.3 | 11.0-14.0 | 1.5-2.5 | 0.3-0.8 | 180-220 | 450-550 |

| Mn14Cr2 | 1.0-1.4 | 13.0-15.0 | 1.5-2.5 | 0.3-0.8 | 190-230 | 480-580 |

| Mn18Cr2 | 1.1-1.4 | 16.0-19.0 | 1.5-2.5 | 0.3-0.8 | 200-250 | 500-600 |

| Mn22Cr2 | 1.2-1.5 | 20.0-23.0 | 1.5-3.0 | 0.3-0.8 | 220-280 | 550-650 |

| Mn22Cr3 | 1.2-1.5 | 20.0-23.0 | 2.5-3.5 | 0.3-0.8 | 240-300 | 580-680 |

High-Chrome White Iron Grades

High-chrome irons provide maximum abrasion resistance for impact-tolerant applications. Used as MMC matrix material and for grinding applications.

| Grade | C (%) | Cr (%) | Mo (%) | Ni (%) | Hardness HRC | Application |

|---|---|---|---|---|---|---|

| 15-3 Cr-Mo | 2.4-3.0 | 14-18 | 2.0-3.5 | 0.5-1.5 | 58-62 | HSI blow bars, mill liners |

| 20-2 Cr-Mo | 2.0-2.8 | 18-23 | 1.5-2.5 | 0.5-1.5 | 60-64 | VSI wear parts |

| 25-3 High-Cr | 2.5-3.2 | 23-28 | 1.0-2.0 | 0.5-1.5 | 62-66 | Maximum abrasion resistance |

| 28-0 Super-Cr | 2.8-3.5 | 26-30 | 0.5-1.5 | 0.3-1.0 | 64-68 | Extreme abrasion, low impact |

Ceramic Insert Specifications

Titanium Carbide (TiC) for Manganese Reinforcement

| Composition | TiC >99% |

| Hardness | 2,800-3,200 HV |

| Density | 4.93 g/cm³ |

| Melting Point | 3,160°C |

| Thermal Expansion | 7.4 × 10⁻⁶ /°C |

| Young’s Modulus | 450 GPa |

| Available Forms | Rods (Ø8-15mm), tiles, strips |

Aluminum Oxide (Al₂O₃) for MMC

| Composition | Al₂O₃ >92% |

| Hardness | 1,600-1,800 HV |

| Density | 3.75-3.95 g/cm³ |

| Flexural Strength | 300-400 MPa |

| Fracture Toughness | 3.5-4.5 MPa·m½ |

| Thermal Shock | Moderate (ΔT ~200°C) |

| Available Forms | Tiles, hexagonal inserts |

Testing Standards & Quality Control

Chemical Analysis

- Optical Emission Spectroscopy (OES): ASTM E415 for steel composition verification

- Combustion Analysis: ASTM E1019 for carbon/sulfur determination

- PMI (Positive Material Identification): XRF verification on finished castings

Mechanical Testing

- Hardness: ASTM E10 (Brinell), ASTM E18 (Rockwell C)

- Impact: ASTM E23 (Charpy) for toughness validation

- Tensile: ASTM E8 where specified

Microstructure Analysis

- Metallography: ASTM E3, E407 for sample preparation and etching

- Grain Size: ASTM E112 comparison method

- Carbide Distribution: Visual rating against reference standards

Non-Destructive Testing

- Ultrasonic: ASTM A609 for internal soundness

- Magnetic Particle: ASTM E709 for surface defects (ferromagnetic only)

- Dimensional: CMM inspection to drawing tolerances (±0.5mm typical)

Material Selection Matrix

Match your duty profile to the optimal material technology. Selection considers impact severity, abrasion intensity, contamination risk, and economic factors.

| Duty Profile | Primary (High Shock) | Secondary (Moderate) | Tertiary/VSI (Low Shock) |

|---|---|---|---|

| Clean, Low Abrasion (Limestone, soft sandstone) |

Plain Mn13-14 | Plain Mn18 or High-Chrome 15% | High-Chrome 20-25% |

| Moderate Abrasion (Granite, basalt, clean quarry) |

Mn18Cr2 or Mn18+TiC | Mn18+TiC or MMC (martensitic) | MMC (high-chrome matrix) |

| High Abrasion (Quartzite, taconite, copper ore) |

Mn22Cr3+TiC | Mn22+TiC or MMC (Ni-Hard) | MMC (high-chrome 25%+) |

| Contaminated Feed (Recycling, rebar, tramp metal) |

Mn18-22 (plain or TiC) | Martensitic steel or Mn+TiC | MMC with martensitic matrix only |

Impact Severity

High impact = favor Mn or Mn+TiC. Low impact = MMC viable. Uncertain = default to Mn-based for safety margin.

Abrasion Intensity

High silica (>65% SiO₂) = upgrade to TiC or MMC. Clean limestone = plain alloys often sufficient.

Contamination Risk

Tramp metal = avoid brittle ceramics. Rebar >5% = martensitic or Mn only. Clean feed = all options open.

Economics

Calculate cost-per-ton, not cost-per-part. Premium materials justify 25-80% upcharge if they deliver 2×+ life.

Manufacturing Process & Quality Control

From melt chemistry to final inspection—critical process controls that determine wear part performance.

Manganese Steel Production

1. Melting & Chemistry Control

- Furnace: Electric arc furnace (EAF) with basic refractory lining

- Charge materials: Low-phosphorus scrap, ferro-manganese, ferro-chrome, carbon additives

- Temperature: Tap at 1,520-1,560°C for optimal fluidity

- Deoxidation: Aluminum and/or calcium-silicon for clean steel

- Sampling: Spectrometer analysis before tap, adjustments as needed

2. Casting Process

- Mold preparation: Chemically-bonded sand molds, vented for gas escape

- Pour temperature: 1,450-1,500°C depending on section thickness

- Feeding: Risers and feeders sized for directional solidification

- TiC insert fixturing: Ceramic inserts positioned before pour, held by chaplets

- Cooling: Controlled cooling rate to minimize residual stress

3. Heat Treatment (Critical)

- Solution treatment: Heat to 1,050-1,100°C, hold 1 hour per 25mm section thickness

- Quenching: Water quench to below 200°C within 30 seconds of furnace exit

- Purpose: Dissolve carbides into austenite matrix, prevent grain boundary carbide films

- Verification: Hardness testing (target HB 180-280 depending on grade), metallography

MMC Production

1. Ceramic Tile Preparation

- Tile specification: Pre-fired Al₂O₃ or ZTA tiles, inspected for cracks and porosity

- Surface preparation: Roughened surface for mechanical bond, optional metallization

- Arrangement: Tiles positioned in mold cavity, secured with ceramic adhesive

- Spacing: 2-4mm gaps between tiles for metal infiltration

2. Metal Matrix Casting

- Melt preparation: Martensitic steel or high-chrome iron per specification

- Pour technique: Controlled pour rate to infiltrate around ceramics without displacement

- Temperature management: Preheated molds to prevent thermal shock to ceramics

- Solidification: Directional cooling from ceramic interface outward

3. Heat Treatment & Finishing

- Stress relief: Controlled cooling or low-temperature anneal to reduce residual stress

- Hardening: Austenitize and quench (or air cool) per matrix alloy requirements

- Tempering: 200-350°C temper for martensitic matrices to optimize toughness

- Inspection: Ultrasonic for ceramic-metal bond integrity, hardness verification

Quality Assurance Protocol

Incoming Materials

Raw material certification review, spectrometer verification of charge materials, ceramic tile inspection.

In-Process

Melt chemistry confirmation, pour temperature logging, heat treatment chart recording.

Final Inspection

Dimensional verification (CMM), hardness mapping, visual inspection, UT for critical parts.

Documentation

Material test certificates, heat treatment records, inspection reports. Full traceability to melt number.

Application Guides by Part Type

Material selection and operating recommendations optimized for cost-per-ton and machine protection.

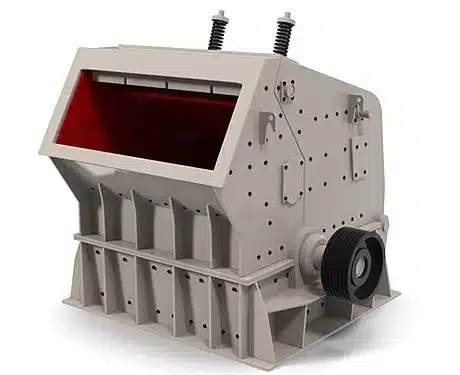

HSI Blow Bars

- Moderate shock, high abrasion: MMC blow bars (martensitic matrix) retain edge profile and stabilize gradation.

- High shock, tramp metal risk: Martensitic steel or Mn+TiC leading edges for breakage protection.

- Clean limestone: High-chrome 18-22% provides best cost-per-ton for predictable feeds.

Operating tip: Tune S1/S2 breaker plate gaps and rotor speed to match material choice. Tighter settings increase impact on bars.

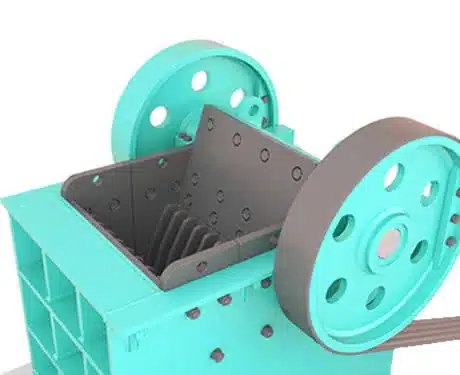

Jaw Plates

- Abrasive feeds with impact: Mn18+TiC or Mn22+TiC at tooth crests to slow nip loss.

- Soft, low-abrasion: Plain Mn13-14 often more economical than composites.

- Variable ore: Mn18Cr2 as baseline, upgrade to TiC if edge wear accelerates.

Operating tip: Replace before design wear limit to protect seats and maintain nip angle. Track tonnes per set for change-out timing.

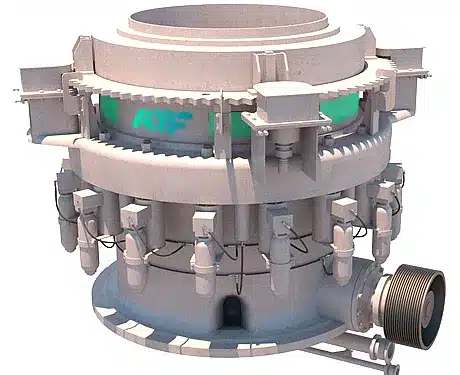

Cone Liners

- Standard: Mn13-Mn22 matched to feed hardness; leverage work-hardening for profile retention.

- Abrasive, moderate impact: Mn22+TiC-reinforced lips to slow rounding (validate insert depth vs. neutral axis).

- Maximum life: MMC option for predictable, low-impact feeds in tertiary position.

Operating tip: Maintain consistent choke feed. Track CSS, power draw, and product gradation to optimize change-out timing.

Technical FAQ — Materials & Innovation

Answers to common questions about MMC composites, TiC inserts, material selection, and manufacturing processes.

When should I choose MMC over TiC-reinforced manganese?

Choose MMC when abrasion dominates and impact is moderate to low—secondary/tertiary HSI, VSI applications, clean recycling. MMC delivers 2-4× wear life but requires controlled impact conditions. Choose TiC+Mn when you need manganese’s shock tolerance but want better edge retention—primary crushing, jaw plates, roughing positions with intermittent impact spikes. TiC+Mn provides 40-60% improvement while maintaining break resistance.

Do ceramic composites increase breakage risk?

Only if misapplied. Ceramics are brittle compared to metals—high-energy impact can fracture ceramic tiles or dislodge TiC inserts. We model insert depth, ceramic coverage, and matrix selection based on your duty profile. For high shock or tramp-metal applications, we favor Mn or Mn+TiC over full MMC. For low-shock, high-abrasion flows, properly designed MMC provides excellent service with minimal break risk.

What heat treatment controls are critical for manganese steel?

Solution treatment at 1,050-1,100°C dissolves carbides into the austenitic matrix. The critical step is rapid water quench—the casting must reach below 200°C within 30 seconds of furnace exit to prevent carbide precipitation at grain boundaries. Slow cooling creates continuous carbide networks that dramatically reduce toughness and cause brittle fracture. We validate every batch with hardness mapping and metallographic examination.

How do you validate that premium materials justify their cost?

We track field KPIs: tonnes per set, change-out frequency, power draw trends, and product gradation stability. Premium materials are approved for rollout only after pilot installations demonstrate cost-per-ton improvement—not just longer life, but economic benefit accounting for material cost premium. Typical targets: 40% cost-per-ton reduction for MMC to justify 60% price premium, requiring at least 2.7× life improvement.

What’s the difference between Mn13, Mn18, and Mn22 grades?

The number indicates nominal manganese content. Mn13 (11-14% Mn) provides good toughness at lower cost for moderate applications. Mn18 (16-19% Mn) is the workhorse grade balancing work-hardening potential and toughness—suitable for most hard rock applications. Mn22 (20-23% Mn) offers maximum work-hardening for highly abrasive ores like porphyry copper and taconite. Higher Mn content increases work-hardened surface hardness but also increases material cost.

How does chromium addition affect manganese steel?

Chromium (typically 1.5-3.5%) improves yield strength and abrasion resistance in manganese steel. Cr promotes carbide formation during solidification, which must be dissolved through proper heat treatment. Mn18Cr2 and Mn22Cr3 grades provide better baseline hardness and wear resistance than plain Mn grades. The tradeoff: higher Cr increases sensitivity to improper heat treatment—carbide networks are more likely if quench is delayed.

Can you retrofit existing wear parts with TiC inserts?

TiC inserts must be cast-in during manufacturing—they cannot be added to existing parts. The metallurgical bond between TiC and manganese forms during solidification at casting temperature. Attempting to weld or braze inserts onto finished parts creates weak bonds that fail in service. If you want TiC reinforcement, specify it when ordering new parts.

What ceramic type is best for MMC—alumina, ZTA, or silicon carbide?

Aluminum oxide (Al₂O₃) is the standard choice—good hardness (1,800 HV), reasonable cost, adequate toughness for most applications. ZTA (zirconia-toughened alumina) adds 10-15% zirconia for improved fracture toughness—better for applications with occasional impact spikes. Silicon carbide (SiC) provides maximum hardness (2,500 HV) but lowest toughness—reserved for extreme abrasion with minimal impact, like VSI tips in clean sand production.

How do I specify MMC or TiC parts for a quote?

Provide: (1) Equipment manufacturer and model, (2) Part number or drawing, (3) Material being crushed (rock type, moisture, contamination), (4) Current wear part material and service life, (5) Primary wear failure mode (edge loss, face wear, breakage). We’ll recommend specific material grade, insert configuration, and expected performance. If you’re unsure about any of these, our engineers can help develop the specification based on your operational description.

What warranty applies to advanced wear materials?

We warrant materials and manufacturing quality—parts are free from casting defects, meet specified chemistry and hardness, and have proper heat treatment. Wear life is not warrantied as it depends on application conditions we cannot control. However, we stand behind our performance projections: if a part significantly underperforms our stated expectations under agreed operating conditions, we investigate and provide resolution—replacement, upgrade, or credit depending on findings.

What’s the typical lead time for MMC and TiC parts?

Standard TiC-reinforced parts: 4-6 weeks (inserts must be positioned before casting). Custom MMC parts: 5-8 weeks (ceramic tile procurement, casting, heat treatment). We maintain stock of common MMC blow bar configurations for faster delivery. For planned maintenance, we recommend ordering 8-10 weeks ahead. Rush production (2-3 weeks) available for emergencies at premium pricing.

Do you provide test certificates and material documentation?

Yes. Every shipment includes: (1) Material test certificate with chemical analysis and hardness results, (2) Heat treatment record showing solution temperature, hold time, and quench details, (3) Dimensional inspection report for critical dimensions. For MMC parts, we also provide ceramic supplier certification. Full traceability to melt number is maintained for all parts.

Explore Advanced Wear Parts

Browse our product range featuring MMC and TiC-reinforced options for maximum wear life.

HSI Blow Bars

High-chrome, martensitic, and MMC ceramic composite options for impact crushers.

Jaw Plates

Standard manganese and TiC-reinforced jaw plates for extended service in abrasive applications.

Cone Liners

Mantles and concaves in standard Mn and TiC-reinforced grades for mining and aggregate.

Request Materials Consultation

Tell us about your application. We’ll recommend the optimal material technology and provide a detailed quote.

35+ years materials engineering experience

Prefer direct contact?

Email: info@atfcs.com

Phone: +1 308 465 1950

What Happens Next?

-

1

Application Analysis

We review your equipment, feed material, and operational requirements

-

2

Material Recommendation

Our engineers specify optimal alloy, insert configuration, and expected performance

-

3

Detailed Quote

Receive pricing with material specifications within 24-48 hours

Materials R&D serving global mining, aggregate & cement

500+ installations with documented performance gains

Full material traceability and test documentation

“ATF’s TiC-reinforced jaw plates increased our service life by 55% in highly abrasive copper ore. The materials recommendation was spot-on.”

— Maintenance Superintendent, Peruvian Copper Mine