About ATF Crusher Parts

ATF Crusher Parts is a China-based manufacturer of wear-resistant castings for crushing equipment, established in 1999. We operate a 50,000 m² ISO 9001 certified facility in Jinhua, Zhejiang Province, producing jaw plates, cone liners, blow bars, and mill components for mining, aggregate, cement, and recycling industries worldwide. Our engineering team provides application-specific material recommendations backed by 35+ years of combined metallurgy experience.

- 35+Years Experience

- 500+Global Customers

- 50+Countries Served

- ISO 9001Certified

Casting Quality Crusher Parts Since 1999

ATF Crusher Parts was established in 1999 in Jinhua, Zhejiang Province, China. We started as a small foundry specializing in wear-resistant castings for local mining operations. Over two decades, we’ve grown into an international supplier serving customers across six continents.

Our Foundation

We began with a straightforward focus: manufacture reliable crusher parts that perform consistently in demanding applications. Our investment in metallurgy research, modern casting equipment, and quality control systems enabled us to deliver components that meet OEM specifications.

Today, we produce wear parts for cone crushers, jaw crushers, impact crushers, grinding mills, and other mining equipment. Our customer base includes quarry operators, mining contractors, cement plants, and equipment dealers who need dependable replacement parts at competitive prices.

Our 50,000 square meter facility in Jinhua, Zhejiang Province

Mission & Values

The principles that guide our manufacturing operations and customer relationships

Our Mission

Deliver quality crusher wear parts that help our customers minimize downtime and control operational costs. We aim to be a reliable supplier that mining operations can depend on for consistent product quality and responsive service.

Our Approach

We focus on manufacturing fundamentals: proper alloy selection, controlled casting processes, and thorough quality inspection. Our engineering team works with customers to match materials and designs to specific applications and operating conditions.

Our Values

- Quality: Consistent manufacturing standards

- Service: Responsive technical support

- Integrity: Honest business practices

- Improvement: Continuous process development

What We Do

We manufacture and supply wear parts for crushing equipment used in mining and aggregate processing operations worldwide

Manufacturing

Our 50,000 square meter facility houses modern casting equipment, heat treatment furnaces, and CNC machining centers. We produce manganese steel, chrome steel, and alloy iron castings for crusher applications.

Engineering Support

Our technical team assists with part selection, material recommendations, and reverse engineering for obsolete components. We work with customers to optimize wear life based on their specific operating conditions.

Global Supply

We export to customers in Asia, Europe, North America, South America, and Africa. Our logistics team handles international shipping, customs documentation, and delivery coordination.

Quality Control

Every casting undergoes chemical analysis, hardness testing, and dimensional inspection. We maintain quality records and can provide material certifications when required by customers.

Custom Solutions

We can manufacture custom wear parts based on drawings or samples. Our engineering team can adapt designs for specific materials or modify dimensions to suit particular applications.

Competitive Pricing

As a direct manufacturer, we offer factory pricing with volume discounts available. We provide detailed quotes including material specifications, lead times, and shipping options.

Our Manufacturing Facility

Our Jinhua facility combines traditional foundry expertise with modern equipment and quality control systems

-

Casting Operations -

Heat Treatment -

CNC Machining -

Quality Laboratory -

Parts Warehouse -

Pattern Shop -

Inspection Area -

Shipping Department

Company Milestones

Key developments in ATF’s growth from local foundry to international supplier

Company Founded

ATF Crusher Parts established in Jinhua, Zhejiang Province, focusing on wear-resistant castings for local mining equipment.

ISO 9001 Certification

Achieved ISO 9001 quality management certification, implementing documented procedures and quality control standards.

International Expansion

Opened Hong Kong export office to serve international markets. Began exporting to customers in Southeast Asia, Europe, and North America.

Facility Upgrade

Invested in new casting equipment and expanded machining capacity to handle larger production volumes and improve delivery times.

Expanded Operations

Increased facility to 50,000 square meters with additional foundry lines and automated material handling systems.

500+ Customer Milestone

Reached over 500 active customers worldwide, serving mining operations, quarries, cement plants, and equipment dealers across six continents.

Management Team

Experienced professionals guiding ATF’s manufacturing operations and customer relationships

David Chen

General Manager

Oversees operations and business development. Background in metallurgy and 20+ years experience in wear parts manufacturing for mining industries.

Sarah Johnson

Technical Director

Manages product development and quality systems. Materials engineering background with expertise in wear-resistant alloys for crushing applications.

Michael Wong

Export Manager

Handles international sales and customer service from our Hong Kong office. Experienced in mining equipment parts and global logistics.

Certifications & Standards

Quality management systems and manufacturing standards that govern our operations

ISO 9001:2015

Our quality management system is certified to ISO 9001:2015 standards. We maintain documented procedures for production control, inspection, and continuous improvement.

Material Testing

In-house laboratory equipment includes spectrometers for chemical analysis and hardness testers for mechanical property verification. We provide material certifications upon request.

Manufacturing Standards

We follow ASTM standards for casting processes and material specifications. Our products are compatible with OEM specifications from major crusher manufacturers.

Environmental Compliance

Our facility complies with Chinese environmental regulations for foundry operations, including emissions control, waste management, and workplace safety standards.

Why Work With ATF

Advantages that distinguish our manufacturing approach and customer service

Direct Manufacturing

We manufacture all our products in-house, controlling quality at every stage from raw material to finished part. No middlemen means better pricing and faster communication.

Technical Knowledge

Our team understands crusher applications and can recommend appropriate materials for different operating conditions. We provide application guidance, not just parts.

Proven Track Record

35+ years in business with hundreds of repeat customers. We’ve supplied parts for operations ranging from small quarries to major mining projects.

Flexible Production

We handle orders from single emergency replacements to container loads for scheduled maintenance. Our production planning accommodates both stock and custom orders.

Quality Assurance

Every part is inspected and documented. We maintain quality records and can trace materials and processes for any component we manufacture.

Global Reach

We ship worldwide and have experience with various international shipping methods, customs requirements, and documentation. Our export team handles logistics coordination.

Frequently Asked Questions

Common questions about ATF Crusher Parts and our services

How long has ATF been manufacturing crusher parts?

ATF Crusher Parts was founded in 1999 in Jinhua, Zhejiang Province, China. We have over 25 years of experience manufacturing wear-resistant castings and crusher components for mining and aggregate industries worldwide.

What types of crusher parts do you manufacture?

We manufacture wear parts for jaw crushers (jaw plates), cone crushers (mantles and concaves), impact crushers (blow bars and impact plates), and other crushing equipment. We also produce components for grinding mills, screens, and material handling systems.

Are your parts compatible with OEM equipment?

Yes. We manufacture parts that are compatible with major equipment brands including Metso, Sandvik, Terex, Hazemag, and others. Our parts are reverse-engineered to match OEM specifications for proper fit and performance.

Do you offer custom manufacturing services?

Yes. We can manufacture custom parts based on drawings, samples, or specifications. Our engineering team can work with you to develop components for specialized applications or obsolete equipment.

What certifications does ATF hold?

ATF is ISO 9001:2015 certified for quality management. We maintain documented procedures for production control, material testing, inspection, and continuous improvement throughout our manufacturing processes.

How can I request a quote for crusher parts?

You can request a quote through our contact form, email, or phone. Please provide equipment model numbers, part descriptions or drawings, and required quantities. We respond to all inquiries within 24 hours with detailed pricing and lead times.

What is the typical lead time for orders?

Standard stock items typically ship within 2-4 weeks. Custom or made-to-order parts require 4-8 weeks depending on complexity and quantity. We can accommodate rush orders for emergency situations—contact us to discuss expedited production.

Do you provide technical support after purchase?

Yes. Our technical team is available to assist with installation guidance, wear pattern analysis, and material recommendations for future orders. We want our parts to perform well in your application and are happy to provide ongoing support.

Explore Our Products

Browse our complete range of crusher wear parts and spare components

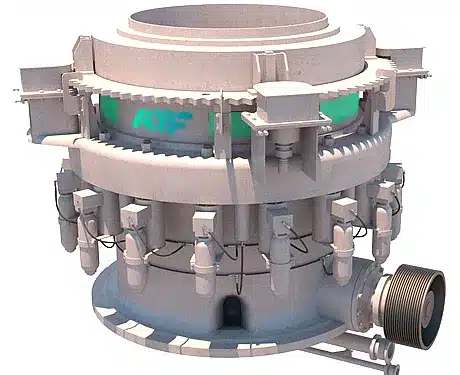

Cone Crusher Parts

Mantles, concaves, and feed cones for secondary and tertiary cone crushers.

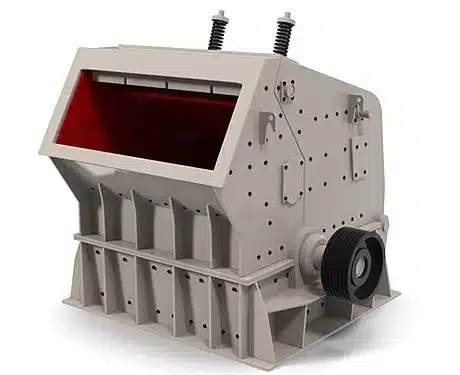

Impact Crusher Parts

Blow bars, impact plates, and side liners for HSI and VSI crushers.

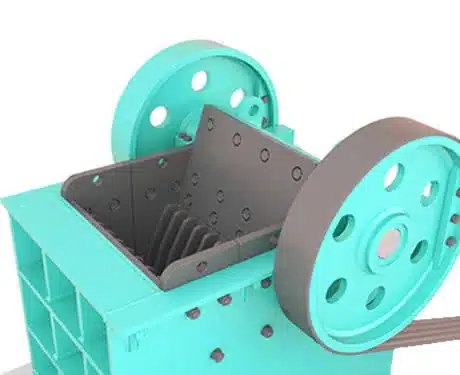

Jaw Crusher Parts

Fixed and swing jaw plates, cheek plates, and toggle plates for jaw crushers.